Precision Spraying Control

High-Efficiency Heating System

Why do some roads begin to crack within a year of use? Why does the road surface become loose, rutted, or even pothole-ridden after the first rainstorm or heavy vehicle traffic? Often, the problem lies not with the material itself, but with uneven asphalt application during construction.

In road construction, asphalt distributors perform a crucial task: evenly spraying heated asphalt between the base and surface layers, forming a solid bond. This seemingly simple process directly determines whether the pavement adheres tightly and can withstand rainwater penetration and long-term loads. Without this step, even the best surface layer will quickly fail due to insufficient bonding.

For this reason, asphalt distributors are called the invisible guardians of road life. From highways to municipal roads, from airport runways to rural highways, they are indispensable in every construction scenario.

Beyond Support: Versatile Uses of Asphalt Distributors

Many people believe that asphalt distributors are merely auxiliary equipment in road construction, primarily serving within the asphalt mixing plant’s construction chain. In reality, their role is far more diverse than imagined: they can collaborate with asphalt mixing plants and asphalt pavers to complete large-scale highway construction, but they can also operate independently, taking on small and medium-sized projects and even emergency repairs.

| In conjunction with asphalt mixing plants: | Asphalt distributors are indispensable for large-scale projects such as highways, airport roads, and municipal arterial roads. They are responsible for spraying a uniform binder coat on the base layer or between layers, ensuring a tight bond between the new and old asphalt layers, thereby enhancing the overall strength and service life of the pavement. |

| Routine road construction and maintenance: | A powerful tool for small and medium-sized projects: When working on small and medium-sized projects such as parking lots, rural roads, and non-motorized vehicle lanes, asphalt distributors can operate independently without the need for an asphalt mixing plant. They can directly apply emulsified or hot asphalt to perform tasks such as sealing, waterproofing, and pothole repair, making them a flexible and efficient construction unit. |

| Emergency and special operations: | In addition to routine road construction and maintenance, asphalt distributors are also frequently used for emergency repairs. For example, if cracks or potholes appear after a heavy rainstorm, asphalt asphalt distributors can be quickly deployed to perform localized spraying, minimizing further road damage and traffic hazards. |

This demonstrates that asphalt distributors are both team players in large-scale projects and independent experts in small-scale construction, truly enabling flexible adaptation across multiple scenarios and roles.

Which type of asphalt distributor is right for your project?

Different road construction environments require varying precision, efficiency, and flexibility in asphalt spraying. For this reason, asphalt distributors are not one-size-fits-all; instead, they come in a variety of types based on their functional configurations and structural forms. Understanding these classifications will help you select the most suitable model from the outset of your project, avoiding rework and increased costs later due to equipment mismatch.

Classification by functional configuration

Basic Asphalt Distributor: An Economical and Durable Starter Choice

Basic asphalt distributors are renowned for their reliability and cost-effectiveness. They are typically operated manually or semi-automatically, feature a simple structure, are easy to maintain, have widely compatible parts, and minimize future investment. They are ideal for projects requiring minimal precision but focused on cost control.

Applicable Scenarios

- Rural Road Seal Application: For lower-grade roads, even spraying is sufficient, and basic sprayers are perfectly suited for this application.

- Repair of older residential areas: For budget-constrained individuals, overly complex equipment is not necessary.

- Agricultural Canal Anti-seepage: Precision spraying is less critical, prioritizing coverage and cost-effectiveness.

- Winter Anti-skid Coating Application in Mountainous Areas: A simple construction environment makes it easier to operate.

Intelligent Asphalt Distributor: Precise and Efficient, Meeting High-Standard Construction Standards

Intelligent asphalt distributors represent a trend in modern road construction. Equipped with automatic temperature control and closed-loop control systems, they adjust spray volume in real time based on vehicle speed and nozzle status. Independent nozzles operate in separate zones, ensuring uniform coverage, minimizing material waste, and ensuring road surface quality.

Applicable Scenarios:

- Composite seal coating for highways: The large-scale construction requires high precision, necessitating intelligent control;

- Bonding layer laying for steel bridge decks: Temperature and thickness accuracy are critical, and only intelligent models can ensure this;

- Anti-rutting layer construction for heavy-duty highways: The high pressure required requires uniform interlayer bonding, making intelligent models a clear advantage.

Classification by structural form

Truck-mounted Asphalt Distributor: Flexible and Maneuverable, the Most Common Workhorse Model

A truck-mounted asphalt distributor mounts the asphalt tank and spraying system directly onto a truck chassis, forming an integrated unit. This design offers high mobility, a high level of integration, and convenient operation, making it particularly suitable for projects requiring frequent cross-site movement. It is currently the most widely used model.

Applicable Scenarios:

- Interregional high-speed construction: Rapid site movement is required, and a truck-mounted asphalt distributor saves time and transportation costs;

- Municipal road construction: Flexible access to and from the construction site reduces traffic disruption;

- Maintenance and inspection: Ready for deployment, small-scale emergency spraying.

Trailer-mounted Asphalt Distributor: An economical choice for fixed-area operations

Trailer-mounted asphalt distributors are primarily trailer-mounted and towed by a tractor. While relatively simple in design, they offer large capacity and high spraying efficiency. They also feature simple equipment and low investment costs, easy maintenance, and a long service life. They are ideal for continuous construction in a fixed area, rather than projects with frequent relocations.

Applicable Scenarios:

- Construction near fixed sites or material yards: Reduces relocation and allows for centralized operations with high efficiency.

- Airport road maintenance: With concentrated areas and high demand, trailer-mounted sprayers offer significant capacity advantages.

- Company-owned construction sites: Low investment costs and suitable for long-term, repeated use within a single area.

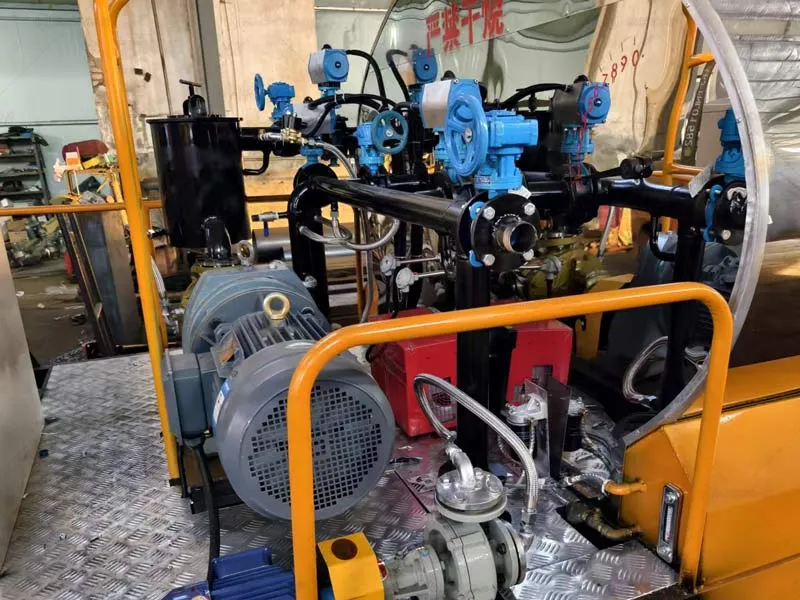

Uncovering the Secrets Behind Asphalt Distributor

After understanding the different types of asphalt distributor and their applicable scenarios, a more critical question becomes: How do they precisely apply the scalding asphalt to the road? On the surface, an asphalt distributor appears to simply spray while driving, but in reality, each even spread is based on a rigorous process, and each step directly impacts the lifespan and construction quality of the road surface.

Heating and Insulation

- After entering the tank, the asphalt is heated to the ideal application temperature by a burner and stabilized by the insulation layer.

- Key Effect: The asphalt maintains excellent fluidity, preventing it from solidifying due to low temperatures or deteriorating due to overheating.

Pressure Circulation

- A dedicated asphalt pump builds pressure, allowing the asphalt to continuously circulate between the tank, pipelines, and nozzles.

- Key Effect: Prevents clogging and ensures the asphalt is always ready for spraying.

Precision Spraying

- The nozzles are arranged in rows at the rear of the vehicle, allowing the operator to open and close them according to vehicle speed and application requirements. Intelligent models also automatically adjust the flow rate and speed.

- Key Effect: Achieve uniform spraying volume and consistent layer thickness.

Synchronous Adjustment

- The asphalt distributor completes the spraying process while in motion, allowing operators to flexibly adjust the spray width, flow rate, and travel speed.

- Key Effect: Adapts to diverse working conditions, including highways, municipal roads, and rural roads.

Uniform Formation

- After spraying, a uniform bond coat or seal layer quickly forms on the road surface.

- Key effect: Strengthen the bonding between the upper asphalt layer and the lower structure, significantly improving the durability and stability of the road.

Human or machine? One comparison reveals the difference

Manual spreading is still common in many small-scale road repairs or remote areas. Workers heat asphalt in drums and then use watering cans or shovels to apply the hot asphalt to the road surface. This method is low-cost, flexible, and suitable for small, temporary projects.

But the problem is that when the construction area expands to hundreds of meters or kilometers, the inefficiency and unevenness of manual spreading become infinitely magnified. This is precisely the purpose of asphalt distributors: to replace the unstable manual method and use mechanization to ensure the long-term quality of roads.

Why is it inevitable that asphalt distributors will replace manual spreading?

| Higher quality requirements: | Modern highways and expressways have strict requirements for the thickness and uniformity of the binder layer, which cannot be accurately controlled by manual methods. |

| Significant safety hazards: | Manual workers need to come into direct contact with hot asphalt, posing a high risk of burns and accidents./td> |

| Different cost calculations: | Manual work may seem cost-effective, but it is inefficient and labor-intensive, making it more expensive than asphalt distributors in the long run. |

| Increasing deadline pressure: | Large and medium-sized projects are generally under tight deadlines, and manual spreading cannot meet the schedule requirements. |

Manual Spreading vs. Asphalt Distributor

Manual spreading still has its place in some small repair projects, but in larger-scale, more demanding road construction, the gap between it and the asphalt distributor is obvious. The following comparison from several dimensions will give you an intuitive understanding of the necessity of the asphalt distributor.

Construction Costs

- Manual Spreading: Equipment investment is almost zero, which may seem cost-effective, but it requires multiple people working for long hours, resulting in high labor costs and time costs.

- Asphalt Distributor: While the initial purchase cost is high, their efficiency and labor requirements are minimal, making them more economical in the long run.

Construction Quality

- Manual Spreading: Relying entirely on workers’ experience, it’s difficult to guarantee the thickness of the asphalt, shortening the road’s lifespan.

- Asphalt Distributor: Through automated or intelligent control, they spray evenly and achieve consistent layer thickness, ensuring the overall durability of the road surface.

Construction Efficiency

- Manual Spreading: Small repairs of a few dozen meters are adequate, but they become inadequate once the work area expands.

- Asphalt Distributor: Easily cover several kilometers of road, exponentially increasing construction speed and significantly shortening construction schedules.

Safety

- Manual Spreading: Workers come into direct contact with hot asphalt, posing a high risk of burns and accidents.

- Asphalt Distributor: Mechanized operation keeps workers away from hot liquids, ensuring a safer construction process.

Manual spreading may still be useful in small-scale emergencies, but in any medium- to large-scale project, an asphalt distributor truck has become an irreplaceable standard equipment. It not only reduces overall costs but also ensures road quality and construction safety.

Configured Right, Works Right

As we’ve seen, asphalt distributors offer significant advantages over manual spreading in terms of efficiency and quality. However, for customers, the true value difference between different asphalt distributor trucks lies not in the comparison of large trucks versus small trucks, but in their configuration and accessories. Some asphalt distributors can operate smoothly and efficiently for years without any issues, while others can experience frequent breakdowns, inaccurate spraying, and even delay project completion. The difference often lies in the details. The following five issues are common to almost every customer and are key factors in determining the value of an asphalt distributor.

Is spraying uniform? — Directly impacts pavement quality.

- Problem scenario: Uneven spraying can lead to locally thick or thin bond coats, directly causing gaps between pavement layers, bulging, or spalling, impacting service life and project acceptance.

- Configuration differences: Ordinary nozzles have limited flow control accuracy; intelligent nozzles feature independent control and closed-loop regulation, automatically adjusting spray volume based on vehicle speed and temperature.

- Customer value: Ensures uniform and consistent spraying quality, avoiding rework and material waste, improving overall project reliability, and safeguarding the construction company’s credibility.

Is it prone to clogging? — A test of construction continuity

- Problem scenarios: Temperature drops or material accumulation can cause nozzle clogging, requiring equipment downtime for cleaning, directly delaying construction progress.

- Configuration differences: Basic vehicles have fewer heating points, resulting in uneven heat distribution; high-end models utilize multi-point combustion and full-process insulation to ensure optimal material flowability.

- Customer value: Achieve continuous and stable spraying, reduce downtime for maintenance, and ensure on-time completion of projects.

Can the equipment lifespan be guaranteed? — The core of return on investment

- Problem scenario: Low-end equipment tanks are prone to corrosion, chassis frequently fail, and maintenance costs rise year by year.

- Configuration differences: Ordinary tanks lack corrosion-resistant treatment; high-quality models use corrosion-resistant steel plates, double-layer insulation, and are equipped with high-grade chassis, resulting in a longer overall lifespan.

- Customer value: Reduced lifecycle costs and extended service life make equipment a reliable asset rather than a consumable.

Is it easy to operate? — The hidden difference in labor costs

- Problem scenario: Traditional asphalt distributors require multiple people to operate, resulting in high labor costs and a high reliance on skilled workers.

- Configuration differences: Manual valves are complex to operate; smart asphalt distributors are equipped with one-touch start/stop and wireless remote control, allowing a single person to complete the entire process.

- Customer value: Reduced labor input, lower training costs, and increased construction flexibility.

Is fault handling efficient? — Ensuring project stability

- Problem scenarios: Construction sites are often located in remote areas with limited maintenance resources. A single failure can cause significant downtime.

- Configuration differences: Low-end models lack self-diagnosis features, making it difficult to detect problems promptly. High-end models integrate automatic cleaning and fault warning systems to proactively address potential problems.

- Customer value: Reduce unplanned downtime, improve equipment availability, and ensure the stable progress of construction projects.

Customer feedback indicates that the value of a spray truck goes far beyond simply completing spraying operations. Rather, it lies in its ability to improve project efficiency, reduce risk, and accelerate return on investment. All of this is determined by its configuration and accessories.

Pre-Purchase Asphalt Distributor Checklist: Ensure Quick Operation

When purchasing an asphalt distributor, many customers tend to focus solely on the equipment itself. However, adequate preparation before purchasing can also impact the equipment’s operational efficiency and future returns. Overlooking these details can lead to delays in commissioning after delivery and even incur additional costs. The following three major preparations are essential for every purchaser.

Project Needs Assessment – Clarify the Construction Environment and Application

Some customers place orders based solely on “needing an asphalt distributor,” ignoring the site environment and specific tasks. As a result, the equipment they receive is either underpowered or oversized, resulting in waste.

Key Recommendations:

- Project Type: Highway, rural road, and bridge deck construction have distinctly different spraying requirements.

- Climate: Cold regions require enhanced insulation systems, while tropical regions require more corrosion protection.

- Material Type: Emulsified asphalt, modified asphalt, and medium-duty asphalt require different spraying systems.

- Clarifying requirements upfront ensures tailored equipment and avoids secondary investment due to incorrect selection.

Confirm supporting conditions – the construction chain must be complete.

Although the asphalt distributor is in place, the site lacks a heating tank or feed pump, or the site is too narrow, preventing the equipment from operating smoothly.

Key Recommendations:

- Confirm the material supply and storage conditions on the construction site

- Check the width and operating radius of the construction road to ensure flexible vehicle access

- Coordinate the connection between the asphalt distributor, the mixing plant, and the paver to ensure continuous construction

- Confirming supporting conditions in advance ensures that the equipment is ready for operation upon arrival, avoiding wasted construction time

Operation and Maintenance Preparation – Get Asphalt Distributor into Operation Quickly

Many construction companies, after purchasing equipment, find they lack skilled workers to operate it, or even simple malfunctions, forcing equipment downtime.

Key Recommendations:

- Arrange for operators to attend manufacturer training to master the control system and basic operations

- Prepare frequently worn parts in advance to reduce waiting time for repairs

- Establish a daily maintenance plan to ensure equipment is in optimal condition

- Proper operation and maintenance preparation ensures long-term stable operation of the equipment and reduces uncontrollable risks.

The true value of a asphalt distributor truck lies not just in its purchase, but in its ability to quickly enter construction, maintain stable operation, and generate a return on investment. All of these require systematic preparation before purchasing the truck.

FAQs

What kind of work can an asphalt distributor perform?

Can asphalt distributors spray hot asphalt? Can they be used in winter?

What capacity asphalt distributor should I choose?

This depends on the scale of your project:

- Small projects or municipal road maintenance: A capacity of 4,000–6,000L is sufficient;

- Medium-sized projects (township and county roads): 8,000–10,000L is more suitable;

- Large highway and national road projects: 10,000–12,000L is more efficient.

If you’re unsure, the manufacturer can provide a customized solution based on the contractor’s daily workload.

What should I do if my asphalt distributor isn’t applying evenly?

How many people are needed to operate an asphalt distributor?

Do asphalt distributor nozzles frequently clog?

What is the typical service life of an asphalt distributor?

Asphalt distributors transform spraying from manual labor to precise, controllable work, improving efficiency while ensuring consistent, long-term construction quality. Whether working on highways or municipal roads, they can be a reliable partner in your projects. If you’re looking for an efficient and durable spreading solution, contact us now to start a more professional construction experience.