Dynamic adjustment technology

Multi-mode drive system

The quality of a road is determined from the moment it’s paved. As hot material slowly spreads ahead, the screed follows closely behind, and the road’s initial shape gradually takes shape, driven by the steel machinery. The asphalt paver is the undisputed protagonist in this process. With steady and precise operation, it evenly and continuously spreads the asphalt mixture onto the roadbed, not only creating a smooth appearance but also laying the foundation for long-term durability. It’s thanks to the asphalt pavers that roads truly move from blueprint to reality.

Where does it add value? — Asphalt Paver Applications

An asphalt paver is more than just a piece of construction equipment; its presence directly determines the smoothness and durability of roads. Different construction scenarios require different performance and adaptability from an asphalt paver machine. Understanding its application range helps you choose the right model and more intuitively understand why it plays an indispensable role in road construction.

| Expressways and freeways: | Long life and high smoothness are required. Asphalt paving machines must have strong continuous operation capabilities and precise leveling systems to ensure safety and comfort at high speeds. |

| Urban roads and municipal engineering projects: | Construction efficiency and maneuverability are emphasized. Asphalt paving machine must operate flexibly within confined spaces while ensuring the appearance and durability of the municipal roads. |

| Rural roads and service roads: | These often face complex terrain and restricted construction environments. Small or multi-purpose asphalt paver machine demonstrate greater adaptability in these applications. |

| Airport and port roads | Load-bearing capacity is extremely demanding, and even the slightest unevenness can impact safety. Asphalt pavers for sale must provide high-precision paving and stable smoothing results. Industrial park and factory roads: Balancing durability and construction costs, pavers must ensure quality while also achieving economic efficiency. |

From highways to municipal projects, from rural roads to large-scale infrastructure, road paver machine is ubiquitous. Their flexible adaptability and precise operation enable road construction to achieve not only speed but also quality and long-term value.

The Power of Coordination: From Mixing to Pavement Formation

In road construction, pavers are often considered the core equipment that determines the apparent quality of the pavement. They are responsible for evenly placing the mix on the road base, directly impacting the road’s smoothness and initial form.

However, truly high-quality pavement doesn’t rely solely on the paver. Asphalt mixing plants, rollers, emulsified asphalt equipment, and asphalt pavers form a tightly coordinated construction chain. Any fluctuation in any link will be reflected in the final road quality.

Asphalt Mixing Plants – Guaranteeing Mixture Quality at the Source

The performance of a paver depends primarily on the mixing quality of the asphalt mixing plant.

- Mixture uniformity: Uneven mixing can lead to irregular aggregate grading and inconsistent temperatures, making it more susceptible to defects such as segregation and loosening after paving.

- Temperature control: The mixture must be maintained within an appropriate temperature range. Excessive cooling can affect compaction, while overheating can cause asphalt degradation, directly shortening the life of the road.

- Feed continuity: Stable and continuous feed ensures uniform paving; otherwise, cold joints and grains will occur.

- Mix ratio accuracy: Even the slightest error in the ratio of asphalt, aggregate, and mineral powder can lead to fluctuations in mixture performance, limiting the paver’s performance.

In short, the asphalt mixing plant is the source of the paver’s operation, determining the quality and stability of the output and directly impacting the foundational quality of the finished pavement.

Rollers – Guaranteeing Density and Durability

If the paver is responsible for “laying the pavement,” then the roller is key to ensuring the pavement is truly formed.

- Initial compaction: This is performed immediately after paving to prevent heat loss and ensure basic formation.

- Secondary compaction: Vibratory rolling is used to further eliminate voids and tightly bind the aggregate.

- Final compaction: This improves surface density, creating a smooth, wear-resistant pavement.

If compaction is insufficient, road defects such as rutting, looseness, and cracking will quickly develop. Conversely, excessive compaction or improper temperature control can also lead to asphalt extrusion and oily pavement. Therefore, the roller’s compaction process must be matched to the asphalt paver’s operating speed to achieve optimal results.

Emulsified Asphalt Equipment – Surface Treatment and Elongation Performance

Emulsified asphalt equipment is commonly used for tack coat, seal coat, and micro-surfacing applications. Its synergistic effect with pavers is demonstrated in the following ways:

- Tack coat spraying: Creates a bonding bridge between the new and old layers, preventing delamination and slippage. Uneven spraying can lead to interlayer delamination even when the paver lays a smooth surface.

- Mist seal/micro-surfacing: Maintains and improves surface functionality, enhancing skid resistance and durability.

- Cold recycling: Mixes emulsified asphalt with old material and paves it again with a paver, achieving environmentally friendly road recycling.

The stability of the emulsified asphalt equipment determines whether the paving process can achieve good interlayer bonding and surface performance.

Asphalt Pavers – a critical step in the initial formation of road surfaces

High-quality mixes enable paver performance to reach its maximum potential. Their automatic leveling system, auger, and screed vibration technology determine the road’s smoothness, thickness consistency, and initial compaction.

However, the paver’s precise operation relies on the coordinated efforts of front-end and rear-end equipment: stable material supply from the mixing plant at the front and timely compaction from the roller at the back ensure seamless road surfaces.

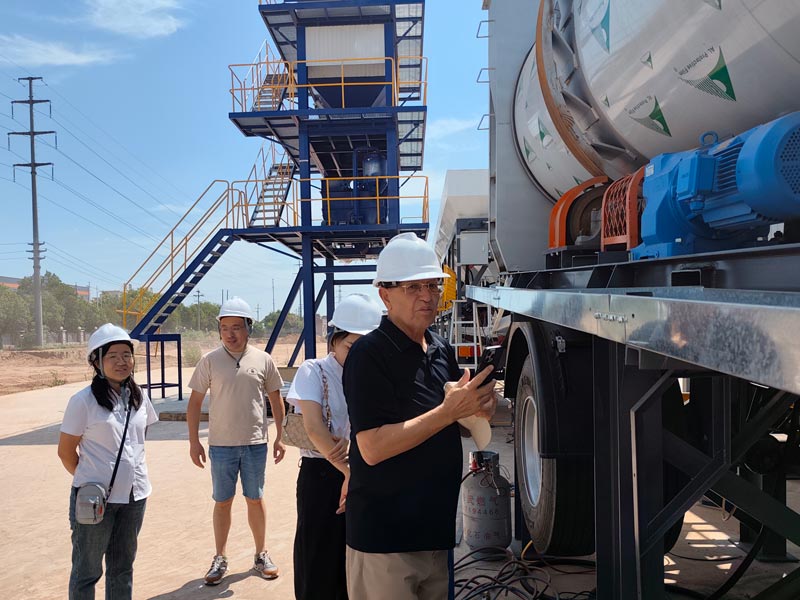

Road construction is a complete industry chain. The asphalt mixing plant determines the quality of the mix; the paver determines the smoothness of the paving; the roller determines the effectiveness of compaction; and the emulsified asphalt equipment determines the interlayer bond and pavement extension performance. Only when these four elements work together efficiently can a smooth, beautiful, and durable road be created. This is not only a test of equipment performance, but also a reflection of the overall collaborative capabilities of the construction team.

Diverse Choices of Asphalt Paver, Precise Fit

Different construction environments place varying demands on asphalt paving machine for sale. Some require flexibility, while others demand stability and efficiency. To meet these diverse needs, Macroad offers two types of asphalt paver: wheeled and crawler. Each type is optimized in performance and detail, ensuring ideal paving results for both municipal roads and highways.

Wheeled Asphalt Pavers

Urban road construction often faces limited space, winding roads, and frequent traffic disruptions, requiring equipment to be highly maneuverable. Wheeled road paving equipment, with their smaller turning radius and higher relocation efficiency, can quickly adapt to narrow sections and complex working conditions. They also offer significant advantages in operations requiring frequent short-distance relocations, maintaining construction efficiency while reducing time lost due to equipment scheduling.

- Applicable Applications: Urban roads, small and medium-sized projects, and projects requiring short-distance relocations.

- Representative Models: APZ45E / APZ60E / APL45E / APL60E

- Key Advantages:

- Hydraulically driven steering system reduces turning radius by 30%, enabling flexible operation in narrow construction sites.

- Modular design reduces routine maintenance time by 50%, significantly minimizing downtime.

- Continuously variable paving speeds of 0–16 m/min enable flexible adaptation to a wide range of working conditions, from municipal roads to residential roads.

Tracked Asphalt Pavers

Highways, airport runways, and mountain roads often require large, continuous construction areas, placing extremely high demands on asphalt road construction machines stability and load-bearing capacity. Tracked pavers offer a large contact patch and low pressure, enabling stable operation on complex terrain, such as soft or sloping surfaces. Furthermore, their wide, scalable paving width and powerful thrust ensure high quality and efficiency even in heavy-duty projects.

- Applicable Applications: Continuous paving over large widths, soft or sloping terrain, and heavy-duty projects.

- Representative Models: APE75 / APE90.

- Key Advantages:

- Rubber track contact pressure ≤0.08 MPa, effectively protecting the compacted base layer.

- Intelligent constant temperature control minimizes mixture temperature fluctuations to ≤±5°C, ensuring paving uniformity and excellent adhesion.

- Paving widths can be expanded up to 15 meters, increasing daily work output by 40%, meeting the efficiency requirements of large-scale projects.

Whether you’re working on urban road construction that prioritizes mobility or heavy-duty projects that demand stability and efficiency, Macroad, as one of the asphalt paving supplies, can provide the best asphalt paver. Choosing the right machine model not only improves construction efficiency but also ensures the long-term quality of the road.

The Craft Behind the Road — How Does An Asphalt Paver Work

As mentioned earlier, different types of paving equipment have their own specific applications. But whether wheeled or tracked, they ultimately accomplish the same task: laying high-temperature asphalt mixture evenly, smoothly, and densely on the road surface. So, how exactly do asphalt paver parts accomplish this seemingly simple, yet in reality complex, process?

Core Structure and Functional Modules in Asphalt Paver

Main System: The core of power and transportation

- Power System: A diesel engine or electric motor provides overall power, driving a hydraulic pump unit through a transfer case, which drives subsystems such as propulsion, feeding, and vibrating.

- Propulsion System: Tracked models are suitable for heavy loads, while wheeled models are more maneuverable. A closed hydraulic circuit combined with microprocessor control ensures consistent and synchronized propulsion, ensuring uniform paving.

Material Delivery and Distribution System

- Scraper Conveyor: Transports asphalt mixture from the dump truck hopper to the rear paving chamber. Contact sensors automatically adjust the feed rate.

- Auger Spreader: Independently hydraulically driven on both sides, distributes material evenly across the entire width, with the material level typically submerging the auger blades to maintain density.

Screeding Device: The key to shaping and compaction

- Vibration Mechanism: The pre-vibrating beam and main vibrating beam alternate at high speeds to initially compact the mixture and reduce voids.

- Vibration Mechanism: High-frequency vibrators provide additional compaction, achieving an initial compaction of 85%-90%.

- Floating screed: Relying on a dynamic balance between its own weight and the material’s resistance, it automatically adapts to the undulations of the base layer, reducing the transmission of unevenness by 50%-70%.

- Heating system: Maintains a screed temperature of 120-150°C to prevent asphalt adhesion and ensure a smooth, even surface.

Key Workflows of Asphalt Paver

Mixture Transportation and Distribution

After the dump truck unloads the asphalt mixture into the hopper, a scraper conveyor feeds the mixture longitudinally, while an auger distributes the mixture horizontally. This ensures a continuous and stable flow of the mixture into the paving chamber, preventing localized material shortages or uneven stacking, and ensuring a consistent paving layer foundation.

Vibration and Initial Compaction

Within the paving area, dual vibrating beams and a high-frequency vibration device work together to provide initial compaction of the mixture. This stabilizes the loose-paving coefficient at 1.15–1.35, creating ideal conditions for the subsequent final compaction by the roller and preventing premature subsidence.

Automatic Leveling and Thickness Control

Longitudinal and transverse slope sensors monitor the road surface in real time, and a hydraulic system automatically adjusts the screed elevation angle based on deviations. Combined with laser or sonar leveling technology, automatic adjustment can be achieved without the need for reference stakes, keeping the flatness error to ≤ 2mm/3m, ensuring precise and consistent pavement thickness and slope.

The three core processes of how does an asphalt paving machine work—stable material feeding, effective compaction, and precise leveling—together constitute the critical process chain for high-quality pavement. Each step is essential: initial material feeding ensures material uniformity, vibration and compaction determine the road’s bearing capacity, and leveling control directly impacts driving comfort and safety. For this reason, asphalt paver models are more than just a paving machine; it is also a guarantor of road life and quality.

Mastering Details, Driving Excellence

When many people look at asphalt pavers, they often focus on engine power, paving width, or screed performance. However, in actual construction, it’s often not these large components that determine efficiency and road surface quality, but rather the often overlooked details. Just as a single skirt belt in an asphalt mixing plant can impact overall loading efficiency, certain small asphalt paver spare parts also silently play a critical role.

Hopper Buffers and Anti-Stick Liners

If the hopper liner is not wear-resistant enough or the surface is heavily adhered, it can lead to poor material feeding, localized material shortages, and uneven paving. High-quality wear-resistant liners and a well-designed buffer ensure continuous material flow and minimize downtime for cleaning.

Auger Blade Wear

The auger is responsible for evenly distributing the material laterally. If the blades are worn or the gap between them increases, uneven material distribution can occur on both sides, causing segregation or loose patches on the pavement. Regular inspection and replacement of the blades can significantly improve pavement uniformity.

Screed Heating System

The screed heating system is often considered merely an auxiliary function to prevent sticking. However, if the temperature is insufficient or the heating is uneven, pavement quality issues such as roughness and segregation can occur. A stable heating system is the invisible guarantee for a smooth pavement.

Sensor and Leveling Beam Accuracy

Automatic leveling systems rely on sensors and leveling beams. If these small components are inaccurate, errors in grade and slope control will occur. Even the best performing tractor can result in wavy or uneven slopes across the entire pavement in asphalt paving machinery.

Hydraulic Pipes and Seals

The hydraulic system drives the core movements of the paver. However, leaks in pipe joints or seals can affect travel, material feeding, and even screed adjustment. Many construction failures are often traced back to these small components. Proper routine maintenance can prevent extensive downtime.

Asphalt paver machine working is a complex system. Large components determine its performance ceiling, while smaller components determine operational stability. Seemingly insignificant details like the liner, blades, sensors, and seals often directly impact smooth paving and a smooth surface. Ignoring these details can lead to project delays and quality risks; paying attention to them can maximize new asphalt pavers for sale efficiency and ensure a more reliable finish.

The Key to Smooth Projects Starts with Choosing the Right Asphalt Paver Supplier

We’ve previously explored in detail the classification, principles, and key details of asphalt pavers. However, simply understanding what is asphalt paving isn’t enough to ensure project success. The value of an asphalt pavers lies not only in its hardware asphalt paver machine specifications but also in the long-term, stable support provided by its supplier. Choosing the right asphalt paver manufacturers, like choosing the right partner for a project, can significantly increase project efficiency.

Comprehensive Technology and Product Line

- Comprehensive Model Coverage: Excellent asphalt pavers manufacturers should offer both tracked and wheeled asphalt paver models, as well as models of varying power levels, to meet the needs of projects of varying scale and complexity.

- Complete Solutions: Beyond selling standalone machines, asphalt paver company can provide integrated asphalt production solutions encompassing pavers + asphalt mixing plants + construction processes tailored to the specific needs of each customer’s project.

- Extensive Application Experience: Proven application case studies across diverse working conditions, including highways, airport roads and municipal roads, ensure the asphalt pavers for sale near me’s adaptability.

Reliable Asphalt Paver Cases and Customer Reputation

- A sufficient number of case studies: A diverse range of real-world project examples provide direct evidence of the supplier’s strength.

- Diverse environments covered: Complex scenarios such as mountainous roads, soft soil foundations, and wide-width continuous paving demonstrate the all in one asphalt paving machine’s adaptability.

- Credible customer reviews: Whether the asphalt paving equipment manufacturers can provide real customer testimonials or user feedback, not just promotional materials.

Comprehensive After-Sales Service and Parts Guarantee

- Fast Parts Supply: With a local parts warehouse, commonly worn parts can be delivered within 24-48 hours, preventing construction delays.

- Timely Service Response: A professional maintenance asphalt paving machine manufacturers are available to quickly respond to on-site or remotely troubleshoot problems as needed.

- Comprehensive Support System: From regular maintenance to emergency repairs, provide clear service procedures and commitments.

Continuous Innovation and Technological Upgrade Capabilities

- Outstanding R&D Capabilities: We have our own R&D team or collaborate with leading research institutions to continuously optimize our products.

- Mature New Technology Applications: Advanced features such as automatic leveling, intelligent sensing, and energy-saving drive have been incorporated into small asphalt paving machines for sale to improve construction quality and efficiency.

- Flexible Upgrades and Expansions: Support for remote upgrades and functional expansion ensures asphalt paver machine for sale remains technologically advanced and prevents rapid obsolescence.

Systematic Training and Operational Guidance

- Comprehensive Training System: Provides comprehensive operational training courses, not just simple demonstrations upon delivery.

- Comprehensive Documentation: Provides detailed operating manuals and instructional videos to help construction teams learn about asphalt paver machine and equipment used in road construction at any time.

- On-site Guidance: Technical personnel can be dispatched on-site during construction to ensure new users quickly get up to speed and reduce operational risks.

Purchasing an asphalt paver isn’t a one-time transaction; it’s the beginning of a long-term partnership. Only by choosing an asphalt paver manufacturer with a comprehensive product line, proven experience, reliable after-sales service, and continuous innovation can your equipment investment truly translate into efficient construction and stable returns.

Strategies for Maximizing Asphalt Paver Utilization

Purchasing an asphalt paver is a long-term investment. Maximizing its asphalt paver price not only impacts construction efficiency but also directly influences return on investment. Maximizing utilization requires systematic management across multiple dimensions, including equipment maintenance, construction strategies, and asset management, to ensure each paver generates maximum asphalt paving pricing throughout its lifecycle.

Scientific and Regular Maintenance of Asphalt Paver

Equipment performance and lifespan directly determine construction quality and operating of asphalt paving machine price. Scientific and regular maintenance can significantly extend equipment lifespan and reduce failure rates, thereby ensuring stable construction and a positive return on investment for road paver machine price.

- Regular inspections of key systems: The hydraulic system, conveying system, and screed unit can detect potential failures and avoid downtime.

- Timely replacement of wearing parts: Maintenance and replacement of key components such as liners, spiral blades, and hydraulic seals ensure long-term, efficient operation of the equipment.

- Cleaning and lubrication management: Maintaining the hopper, conveying system, and screed plate clean and lubricated reduces wear and adhesion, thereby improving equipment efficiency.

Efficient Construction and Optimized Operation of Asphalt Paver

Rational planning of construction plans and operational procedures for asphalt paver cost can improve equipment utilization and reduce unnecessary wear and tear.

- Matching machine models to project requirements: Select the most appropriate machine model based on road section type, width, asphalt paver machine price and working conditions to avoid wasted resources or overloading.

- Optimizing construction rhythm: Scientifically scheduling work schedules and construction sequences to reduce frequent starts and stops and inefficient operations, thereby improving construction efficiency.

- Operator training: Systematically improve operator skills through training to reduce equipment damage caused by human error.

Idle Management and Leasing Strategies of Asphalt Paver

Rationally utilizing idle equipment time can generate additional revenue and maintain equipment activity.

- Idle Maintenance: Perform maintenance, lubrication, and rust prevention during the off-season to keep equipment ready for immediate use.

- Short-term Leasing: Leasing equipment to other construction companies for periodic construction or small projects maximizes asset value.

- Shared Operations: Establish a sharing mechanism with construction partners to increase equipment utilization and reduce idle costs.

Data-driven Management and Operational Analysis of Asphalt Paver

Digitally recording equipment usage data and construction performance enables scientific decision-making and improved utilization efficiency.

- Operational Data Monitoring: Records working hours, paving volume, and fault conditions for each construction phase, providing a basis for operational optimization.

- Maintenance Record Management: Establishes a record of parts replacement and maintenance to implement preventive maintenance and extend equipment life.

- Performance Evaluation and Optimization: Analyzes equipment utilization and construction quality, optimizes scheduling and operation strategies, and improves return on investment.

Secondhand Value and Asset Extension of Asphalt Paver

Good full-lifecycle management not only extends the service life but also increases its value in the secondhand market, ensuring future upgrades or capital recovery.

- Comprehensive Maintenance Records: Complete maintenance and repair records enhance credibility and transaction value in the secondhand market.

- Equipment Condition Assessment: Regularly assess the wear and tear of key components to provide guidance for sale or replacement.

- Brand and Parts Advantages: Select equipment with reliable brands and readily available parts to ensure secondhand circulation and reinvestment value.

Maximizing the value of an asphalt paver depends not only on the equipment itself but also on a systematic operational strategy, scientific maintenance, rational construction management, and asset optimization. Through full-lifecycle management and refined operations, each paver can achieve efficient operation, extend its lifespan, and continue to generate economic value in how much is asphalt paving through subsequent secondhand sales or rentals.

Asphalt pavers are essential core equipment in road construction, and their performance, operation, and management directly impact construction efficiency and road surface quality. By thoroughly understanding machine model selection, operating principles, key components and details, supplier selection, and lifecycle utilization strategies, you can make informed choices, optimize operations, extend equipment life, and create additional value in the idle or used market.

Choosing a reliable partner is crucial. With proven technology, extensive engineering experience, and comprehensive after-sales and training services, Macroad ensures that each asphalt paver achieves its full potential within a project, making investments more efficient and robust, and providing customers with long-term, reliable protection.