Highly efficient mixing and emulsification performance

Wide range of application scenarios

In the field of road construction and maintenance, emulsified asphalt is becoming an important direction of industry development due to its advantages of environmental protection, energy saving, and convenient construction. As the core tool for producing emulsified asphalt, emulsified asphalt equipment is also gaining more and more attention. If you want to keep up with this industry trend, this guide will give you a comprehensive understanding of the relevant knowledge of asphalt emulsification equipment.

What is emulsified asphalt equipment?

To keep up with the trend in this field, the first and most important thing is to understand what is emulsified asphalt? How does the asphalt emulsification equipment work?

Emulsified asphalt is a stable emulsion formed by mixing asphalt with water and emulsifier under a specific process. It overcomes the problems of high temperature, high energy consumption and serious pollution in traditional hot asphalt construction. Asphalt emulsification equipment is a special equipment specially used to achieve this conversion process.

Simply put, the asphalt emulsification equipment heats the asphalt, mixes and heats the mixture of water and emulsifier (water phase), and then sends the two into the colloid mill for high-speed shearing and grinding in a certain proportion, and finally produces uniform and stable emulsified asphalt. It is the key bridge connecting asphalt raw materials and emulsified asphalt products, and is also the core guarantee for promoting the widespread application of emulsified asphalt in road engineering.

Core Advantages

| Efficient mixing: | fully combine asphalt with water and emulsifier to break the barrier of oil and water immiscibility. |

| Particle size control: | through high-speed shear technology, ensure that the asphalt particles are small and uniform (usually 1-5 microns) to improve the stability of the emulsion. |

| Temperature management: | accurately control the production temperature to avoid asphalt aging or emulsion stratification. |

| Energy saving and environmental protection: | cold construction reduces fuel consumption and reduces carbon dioxide emissions. |

Core structure and technical parameters of emulsified asphalt equipment

Above we have roughly introduced the working process of asphalt emulsification equipment, but if you want to have a deeper understanding, a simple introduction is not enough. Next, let us take a look at the core structure and process flow of an emulsified asphalt equipment and the parameters of the Macroad asphalt emulsification equipment.

Asphalt Emulsification Equipment

The following are the main technical parameters of the common asphalt emulsification equipment mainly sold by Macroad. The parameters of different models of equipment will vary:

- Equipment size: 6 meters long, 2.2 meters wide, 2.4 meters high (not fixed, can be adjusted according to the model and configuration)

- Heating method: direct heating burner heating, thermal oil heating

- Colloid mill power: 22-37 kilowatts

- Asphalt heating temperature: about 130℃

- Water heating temperature: about 60℃

Detailed explanation of core structure and process

The core structure of a complete emulsified asphalt equipment revolves around four major links: asphalt treatment, water phase treatment, mixing and shearing, and control system. The entire production process and production process mainly include:

Asphalt heating system

Responsible for heating solid or high-viscosity asphalt to a specific temperature (usually around 130°C) to make it have good fluidity for subsequent processing. Common heating components of asphalt emulsification equipment include burners, thermal oil heaters, etc.

Water phase (emulsifier solution) preparation system

Composed of a water tank, an emulsifier addition device, a stirring device and a heating device. It is used to heat water to a suitable temperature (usually around 60°C) and fully mix it with the emulsifier to form a uniform water phase solution.

Colloid mill

This is the heart of the asphalt emulsification equipment. Through the strong shearing and grinding action between the high-speed rotating rotor and the stator, the asphalt particles are broken and evenly dispersed into the water phase to form a stable emulsified asphalt. Its performance directly affects the fineness and stability of the emulsified asphalt.

Transportation and metering system

Including asphalt pumps, water pumps, flow meters, etc., used to accurately control the delivery volume of asphalt and water phase to ensure that the two are mixed in a set ratio.

Control system

It is composed of control cabinets, sensors, instruments, etc., which can realize accurate control of parameters such as temperature, flow, stirring speed, etc., to ensure the stability and efficiency of the production process.

Finished product storage

The produced emulsified asphalt is temporarily stored in the finished product tank, waiting for use or transportation.

Application scenarios of emulsified asphalt equipment

Asphalt emulsification equipment has a wide range of application scenarios, and its customer groups are mainly concentrated in areas related to road construction and maintenance, as follows:

- Road maintenance units: including local highway bureaus, municipal engineering departments, maintenance companies, etc. Mainly used for daily road minor repairs and maintenance, such as crack repair, pavement sealing (slurry sealing, micro-surfacing, etc.). Such scenarios have certain requirements for the flexibility and mobility of the equipment.

- Road construction companies: In new highways, municipal roads, rural roads and other projects, used for the construction of base or surface layers, such as cold recycling construction, gravel sealing, etc., usually require equipment with larger production capacity.

- Asphalt mixing Plants: Some asphalt mixing plants will be equipped with emulsified asphalt equipment to expand product lines and provide customers with a variety of asphalt materials.

- Operation and maintenance units in places such as airports and ports: used for the construction and maintenance of airport runways, aprons, and port roads. Such scenarios have higher performance requirements for emulsified asphalt, and correspondingly, the accuracy and stability requirements of the equipment are also more stringent.

- Internal road construction units such as mines and industrial parks: used for the laying and maintenance of self-built internal roads, mostly choose small and medium-sized equipment to meet their own needs.

Classification of emulsified asphalt equipment

Just like asphalt plants, different application scenarios have different requirements for equipment. There are various ways to classify asphalt emulsification equipment. The asphalt emulsification equipment corresponding to different classification standards has differences in function and applicable scenarios. The following are common classification methods and specific descriptions:

Classification by movement mode

Stationary emulsified asphalt equipment

- Equipment introduction: The equipment is fixedly installed in the factory or a specific site as a whole and cannot be moved at will. It is usually equipped with a large-capacity raw material storage tank and an automated control system.

- Core features: large production capacity (mostly medium-sized and above), high production efficiency, long-term stable operation, suitable for linkage with other large equipment.

- Applicable scenarios: supporting production of large asphalt mixing stations, professional emulsified asphalt processing plants, large-scale production bases at fixed sites, etc., which have large production capacity requirements and fixed production locations.

Mobile emulsified asphalt equipment

- Equipment introduction: The equipment is integrated in a trailer, truck chassis or container, and can be moved across sites by towing or self-driving.

- Core features: strong flexibility, convenient transfer, small footprint, and some small mobile equipment can achieve immediate production upon arrival.

- Applicable scenarios: road maintenance projects (such as township road repairs, local maintenance of urban roads), small construction projects, and scenes that require rotation of operations between multiple construction sites, especially suitable for emergency repairs or decentralized construction needs.

Classification by production method

Continuous equipment

- Equipment introduction: Adopting the asphalt production mode of continuous input of raw materials – online mixing – continuous output, the real-time ratio of asphalt, water and emulsifier is controlled by a precise metering system, and the production process is uninterrupted.

- Core features: high production efficiency (hourly production capacity can reach tens of tons), strong product stability (small batch difference), suitable for standardized large-scale production.

- Applicable scenarios: new construction of highways, construction of municipal trunk roads, large-scale slurry sealing/micro-surfacing projects, etc., which require continuous supply of a large amount of emulsified asphalt.

Intermittent equipment

- Equipment introduction: Adopting the mode of batch feeding – batch production – batch discharge like asphalt batching plant, the raw material ratio and process parameters can be flexibly adjusted before each batch of production, and the single batch output ranges from a few tons to more than ten tons.

- Core features: flexible formula adjustment, suitable for small-batch production of multiple varieties, relatively simple equipment structure, and low initial investment.

- Applicable scenarios: scientific research experiments, alternating production of multiple types of emulsified asphalt (such as ordinary emulsified asphalt, modified emulsified asphalt), or small-scale maintenance projects (such as rural road repairs, local crack treatment) and other small-batch demand scenarios.

Classification by emulsifier type

The charge properties of the emulsifier determine the polarity of the emulsified asphalt. The asphalt emulsification equipment needs to be adapted to the corresponding type of emulsifier, so the following classifications are derived:

Cationic emulsified asphalt equipment

- Equipment introduction: Designed specifically for the production of cationic emulsified asphalt. The equipment material (such as pipelines and storage tanks) needs to be adapted to the chemical properties of the cationic emulsifier to avoid corrosion or reaction that affects the stability of the product.

- Core features: The emulsion is positively charged and has strong adhesion to acidic stones (such as granite and quartzite). The demulsification speed can be adjusted through the formula (fast cracking, medium cracking, slow cracking).

- Applicable scenarios: Road construction in rainy areas (good water stripping resistance), projects that require rapid curing (such as gravel seal), and base/surface construction with acidic stones as the main materials.

Anionic emulsified asphalt equipment

- Equipment introduction: Adapted to anionic emulsifiers, the equipment material needs to be compatible with its chemical properties (such as avoiding reactions with strong alkaline materials).

- Core features: The emulsion is negatively charged, has excellent adhesion to alkaline stone (such as limestone and dolomite), has a relatively slow demulsification speed, and a longer construction window period.

- Applicable scenarios: road construction in dry climate areas, large-area paving that requires delayed demulsification time (such as cold recycled base), projects mainly based on alkaline stone, or scenarios with loose requirements on construction time.

Classification by heating method

Heating is a key link in the production of emulsified asphalt. Different heating methods directly affect the stability of asphalt and the applicable scenarios of the asphalt emulsification equipment:

Direct heating burner heating equipment

- Equipment introduction: The asphalt tank and water tank are directly heated by the burner (fuel or gas), the heat transfer is direct, and the heating speed is fast (asphalt can be heated from room temperature to 130℃ within 1-2 hours).

- Core features: high heating efficiency, low energy consumption, simple equipment structure (no complex heat transfer oil circulation system), low initial investment cost, but relatively low temperature control accuracy (local temperature difference may reach ±5℃).

- Applicable scenarios: scenarios with high requirements for heating speed, strong production continuity but low temperature sensitivity, such as rural road construction, small and medium-sized maintenance projects, emergency repairs, etc., especially suitable for grassroots construction or ordinary projects with general requirements for emulsified asphalt stability.

Thermal oil heating equipment

- Equipment introduction: Indirect heating method of thermal oil circulation is adopted: the burner heats the thermal oil, and the hot oil flows through the interlayer of the asphalt tank and the water tank through the pipeline to achieve uniform heating, and the temperature fluctuation can be controlled within ±2℃.

- Core features: uniform heating, avoiding asphalt aging or emulsifier failure caused by local overheating, and can accurately control the temperature, which is suitable for scenes with high requirements for raw material quality.

- Applicable scenes: highway micro-surfacing, airport runway maintenance, modified emulsified asphalt production and other projects with strict requirements on the quality of emulsified asphalt, especially suitable for high-precision construction scenes that require long-term stable production and are sensitive to temperature.

How to choose suitable emulsified asphalt equipment

Since there are many types of asphalt emulsification equipment, choosing the right emulsified asphalt equipment is essential to join the emulsified asphalt industry. The selection of emulsified asphalt equipment needs to comprehensively consider its own needs and equipment performance. The following are some key factors:

| Capacity requirements: | Determine the hourly capacity of the equipment according to your own production scale or construction progress. If it is a large-scale engineering project, you should choose medium-sized and large-sized equipment; small-scale maintenance projects can choose small equipment. |

| Construction scenario: | If you need to move between multiple sites, mobile equipment is preferred; if the production location is fixed, fixed equipment is more suitable. |

| Emulsified asphalt type and quality requirements: | Different types of emulsified asphalt (such as ordinary emulsified asphalt, modified emulsified asphalt, etc.) have different requirements for equipment. If you need to produce high-quality or special types of emulsified asphalt, you should choose equipment with higher configuration (such as high-performance colloid mill, precise control system). |

| Heating method: | Direct heating burner heating equipment has a fast heating speed, but the temperature control accuracy is relatively low; thermal oil heating equipment has more uniform temperature control and is suitable for temperature-sensitive emulsified asphalt production. It can be selected according to actual needs. |

| Budget: | Under the premise of meeting production needs, choose cost-effective equipment based on your own budget. At the same time, long-term costs such as equipment operating costs and maintenance costs should also be considered. |

| Equipment stability and after-sales service: | Choose an asphalt equipment manufacturers with good reputation and mature technology to ensure stable operation of the equipment and timely after-sales service, such as equipment installation and commissioning, maintenance, and spare parts supply. |

Market analysis of emulsified asphalt equipment

Now you have a more detailed understanding of the overall emulsified asphalt equipment. If you are still considering whether to invest in emulsified asphalt equipment, perhaps the following market analysis will help you make a choice.

Overall market development trend and overview

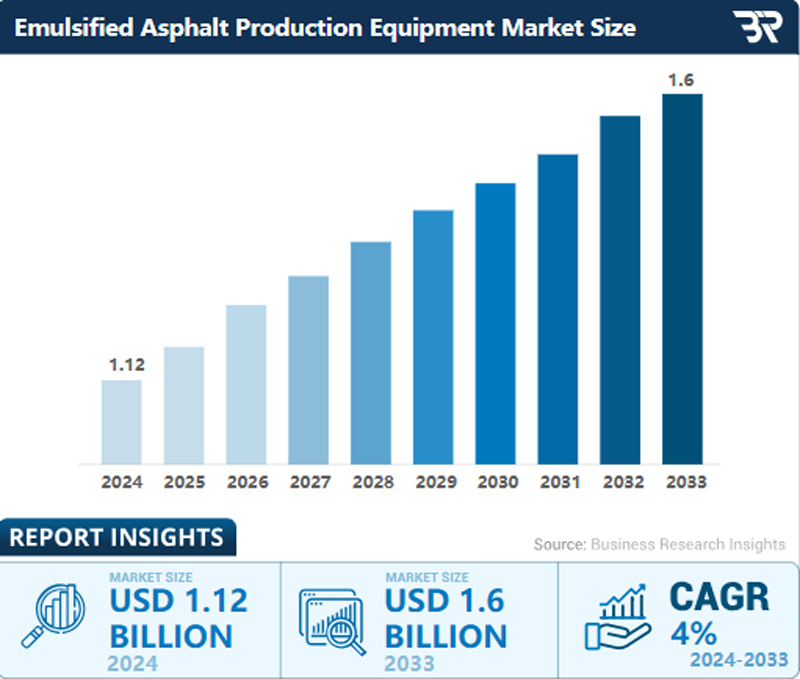

In recent years, with the continuous improvement of road network, the demand for road maintenance has been increasing. At the same time, the global requirements for environmental protection and energy conservation have been continuously improved. As an environmentally friendly pavement material, the application scope of emulsified asphalt continues to expand, driving the development of the emulsified asphalt equipment market.

From the overall point of view, the emulsified asphalt equipment market presents the following trends:

- Steady growth in market demand: Affected by factors such as the expansion of the road maintenance market and the increase in the proportion of emulsified asphalt in new roads, the demand for emulsified asphalt equipment has increased year by year.

- Continuous technology upgrading: In order to meet the production needs of higher quality emulsified asphalt, the technology of equipment in automation control, energy saving and consumption reduction, production efficiency, etc. has been continuously improved, such as the application of intelligent control systems and the adoption of high-efficiency and energy-saving heating technologies.

- Products are developing towards diversification and customization: The needs of different customers vary greatly, and equipment manufacturers are increasingly focusing on providing personalized solutions and customizing special equipment according to customer production capacity, construction scenarios, product types and other needs.

Analysis of market segment prospects

Highway market

Highways have long mileage and high maintenance standards, and the demand for emulsified asphalt is large, and the quality requirements for emulsified asphalt are strict. As highways enter the large-scale maintenance period, the demand for high-performance emulsified asphalt equipment will continue to grow steadily, and the market prospects are broad.

Municipal road market

Municipal roads include urban main roads, secondary roads, branch roads, etc., with high maintenance frequency and scattered construction sites. Small and mobile emulsified asphalt equipment is widely used in municipal road maintenance. With the advancement of urbanization and the increase in investment in municipal road construction, the demand for equipment in this market segment will continue to rise, and the prospects are good.

Airport road market

Airport runways, aprons, etc. have extremely high performance requirements for pavement materials. Emulsified asphalt is also used in the construction and maintenance of airport roads. Although the scale of the airport road market is relatively small, it has high requirements for the technical content and stability of equipment, high equipment added value, and good development potential.

Rural road market

With the implementation of the rural revitalization strategy, the construction and renovation of rural roads have been intensified. Emulsified asphalt is increasingly used in rural road projects due to its advantages such as convenient construction and relatively low cost. The demand for small and medium-sized emulsified asphalt equipment will be gradually released, and the market space is relatively large.

In general, the expressway and municipal road markets are the main areas for the application of emulsified asphalt equipment due to their large demand scale and stable growth, and have relatively broader prospects; the airport road and rural road markets also have their own characteristics and have good development potential.

FAQs

Q: What is the price range of emulsified asphalt equipment?

Q: What should be paid attention to in the maintenance of emulsified asphalt equipment?

Q: Can one emulsified asphalt equipment produce multiple types of emulsified asphalt?

Q: After purchasing emulsified asphalt equipment, will the manufacturer provide technical support?

Q: If I have an emulsified asphalt plant, does that mean I no longer need an asphalt mixing plant?

Through the above content, I believe you have a more comprehensive understanding of emulsified asphalt equipment. Whether it is used for road construction and maintenance, or engaged in the emulsified asphalt production industry, understanding the performance, process, market and other information of the equipment can help you make more informed decisions and better grasp the development opportunities of the industry. If you have further needs, such as equipment selection consultation, technical details, etc., you can fill in the form below at any time and communicate your project needs with us at any time.