Precisely control the proportion of modifier addition

Intelligent temperature control and stirring system

As road construction standards continue to rise, conventional asphalt is gradually exposing its limitations, such as high-temperature rutting, low-temperature cracking, and insufficient durability. To meet the higher performance requirements of projects like highways, airports, and municipal roads, modified asphalt has become an inevitable choice for the industry.

Modified asphalt significantly improves high-temperature stability, low-temperature crack resistance, and durability by adding modifiers such as SBS or rubber powder. However, stable, mass-produced high-quality modified asphalt requires specialized modified asphalt production plant—precise heating, intelligent mixing, and automated proportioning—to ensure consistent performance in each batch, meeting stringent project standards.

The value and use of modified asphalt

As road construction standards continue to improve, the shortcomings of traditional asphalt, such as rutting at high temperatures, cracking at low temperatures, and insufficient durability, have gradually become apparent. Consequently, an increasing number of road construction projects are turning to modified asphalt, not only for better pavement performance but also to reduce long-term maintenance costs and extend road life.

Core Values of Modified Asphalt

| Adaptability to Extreme Climates: | Maintains excellent performance in both hot summers and cold winters, making it suitable for areas with complex climates. |

| Excellent Durability: | Resists cracking or deformation under heavy traffic and frequent use, significantly extending the life of roads. |

| Stronger Adhesion: | Provides a tighter bond with aggregate, reducing delamination and improving overall pavement stability. |

| Sustainability: | Utilizing recycled materials such as scrap tire rubber helps reduce waste and minimize environmental impact. |

| Long-Term Cost-Effectiveness: | While the initial investment may be higher than that of conventional asphalt, lower maintenance costs and a longer service life provide higher returns. |

Key Application Scenarios

Modified asphalt production plant is widely used worldwide, particularly in projects requiring high road performance:

| Expressways and urban arterial roads: | Withstand long-term, high-intensity traffic pressure and maintain a smooth surface. |

| Airport runways and bridge projects: | Meet high safety and durability standards. |

| Municipal roads and overpasses: | Improve the comfort and service life of municipal roads. |

| Roads in extreme climates: | Address material challenges posed by high temperatures or freezing temperatures. |

In these projects, high-quality modified asphalt production plant is crucial for ensuring construction quality and production efficiency.

Different needs, different choices: two types of modified asphalt production plant

In practice, project scales, construction environments, and performance requirements vary. To make it easier for customers to find the right solution, Macroad categorizes its modified asphalt equipment into two core types, each tailored to specific construction needs.

Standard Modified Emulsified Asphalt Production Plant

This type of modified asphalt production plant is compact and easy to operate, making it ideal for small and medium-sized projects or construction scenarios requiring flexible scheduling.

- Equipment Dimensions: Typical specifications are approximately 7.5m × 2.2m × 2.4m, requiring minimal space and easy transportation and installation.

- Flexible Heating Methods: Supports direct-heat burner or thermal oil heating, selectable based on site conditions.

- Intelligent Proportioning System: Features built-in solids content detection, automatically adjusting the asphalt-to-water ratio to ensure consistent finished product quality.

- Heat Exchange Design: Equipped with a finished product heating heat exchanger to enhance emulsified asphalt application performance.

- Energy Consumption and Output: Mill power is approximately 45-55kW, offering an excellent balance between efficiency and energy consumption.

- Suitable Applications: Municipal roads, small-scale repair projects, or multi-site projects.

Rubber-Modified Asphalt Production Plant

This type of modified asphalt production plant is the preferred choice for projects requiring higher production and performance of modified asphalt.

- Customizable Size: Production capacity can be customized according to project requirements, typically supporting 10-30 cubic meters per hour.

- Stable Heating System: Utilizes thermal oil heating, and requires a thermal oil boiler to ensure stable heating of the asphalt to 180°C, meeting the process requirements for SBS or rubber modification.

- High-Shear Mixing Capacity: A high-shear mill with a power of 55-120kW ensures thorough dispersion of the modifier and more stable finished product performance.

- Simple and Intuitive Control: Core parameters are precisely controlled, with flexible adjustment of temperature and shear force, making it easy for operators to operate.

- Efficient Heat Exchange: A large-area heat exchanger design delivers high energy efficiency and low heat loss.

- Suitable Applications: Large infrastructure projects such as highways, airport runways, and bridges.

With the support of these two types of modified asphalt production plants, Macroad can cover all needs from small municipal roads to large highway and airport projects, helping you achieve efficient, stable and economical modified asphalt production in different scenarios.

Production principles of modified asphalt production plant

With the support of the various equipment mentioned above, the asphalt production of modified asphalt is not just an assembly line, but a process system that requires precise control. Only when each link is closely connected can the modified asphalt ensure excellent road performance.

Production Process

Heating the Asphalt: The production process begins by heating the base asphalt to a specific temperature, typically between 150°C and 180°C. Heating reduces the asphalt’s viscosity, making it easier to mix with the modifier.

Adding the Modifier: Once the asphalt reaches the required temperature, the modifier can be added. The mixing process must ensure that the modifier is thoroughly incorporated into the asphalt. High-shear mixing techniques are typically used to provide the necessary energy for uniform dispersion of the modifier.

Quality Control: Quality control is a critical aspect of modified asphalt production. Samples are collected at various stages to test properties such as viscosity, elasticity, and temperature sensitivity. These tests ensure that the modified asphalt meets industry standards and is suitable for its intended application.

Storage and Transportation: After passing quality inspection, the modified asphalt is transferred to storage tanks. The material must be maintained at the appropriate temperature until it is ready for transportation to the construction site.

Modified asphalt production plant working process detail

In this complete production process, Macroad modified asphalt equipment works in conjunction with a variety of supporting materials to ensure stable and efficient production at every stage:

Modifier Addition

- Polymers (SBS, EVA): Improve asphalt elasticity and temperature adaptability, preventing pavement cracking and deformation.

- Ground Rubber (GTR): Enhances durability and wear resistance while also repurposing waste tires.

- Chemical Additives: Such as anti-stripping agents and adhesion promoters, improve the adhesion between asphalt and aggregate.

Production Equipment

- Heating Device: Ensures that the base asphalt and modifier reach the ideal temperature, creating conditions for uniform mixing.

- High Shear Mixing Tank: The core unit, ensuring the complete integration of the modifier and asphalt, is crucial to the performance of the finished product.

- Storage Tank: Insulated design ensures that the finished product maintains stable temperature and quality before transportation.

Pumping and Transportation System

- Specialized Pumping Equipment: Maintains the fluidity and stable performance of the asphalt during transportation.

- Insulated transport vehicles: Temperature control throughout the entire process ensures that the modified asphalt remains in optimal condition when it arrives at the construction site.

The key to project success: mastering the response strategy for each link

Once you’ve mastered the basics of modified asphalt equipment, the project truly begins. However, any project is a complex whole, with every step impacting the final outcome. Therefore, a clear understanding of each project step, along with foresight and appropriate solutions, is crucial to ensuring smooth, efficient, and cost-effective construction.

Modified Asphalt Production Plant Selection and Capacity Matching

- Possible Situations: Projects vary in size and construction schedules are tight. Blindly selecting equipment can easily lead to insufficient capacity or excessive capital utilization.

- Our Solution: We provide customized selection solutions based on project size, daily production requirements, construction schedule, and budget. We also simulate production capacity and construction schedules to ensure equipment is perfectly matched to the project and investment is profitable.

Production Efficiency and Construction Quality

- Possible Situations: High temperatures or long construction times can affect mixing uniformity, leading to unstable finished product performance. Equipment operation is complex and prone to errors during construction.

- Our Solution: High-shear mixing, high-precision temperature control, and intelligent automation systems ensure uniform mixing and stable performance. Real-time monitoring and automated control streamline operational processes, reduce human intervention, and improve production efficiency and construction quality.

Material Usage and Cost Control

- Possible Situations: Inaccurate modifier ratios can lead to significant material waste and poor finished product consistency.

- Our Solution: Automated mixing and solids content detection systems precisely control the asphalt to modifier ratio, ensuring that every batch meets standard requirements. This effectively reduces material loss, ensures consistent finished product performance, and controls production costs.

Transportation and Construction Site Management

- Possible Situations: Long-distance transportation or multiple construction sites may cause asphalt cooling and fluctuating properties, increasing construction risks.

- Our Solution: Insulated storage tanks, dedicated pumping systems, and heated transport vehicles ensure temperature control throughout the entire process from production to the construction site, maintaining optimal material properties. Construction teams can focus on construction without worrying about transportation or site conditions.

Post-Maintenance and Long-Term Return on Investment

- Possible Situations: Short equipment component lifespan, complex maintenance, and high long-term costs; project expansion or capacity increases require the purchase of new equipment.

- Our Solution: Upgraded wear-resistant components, modular construction, and predictive maintenance design ensure critical components have a lifespan of up to millions of tons, reducing downtime and repair costs. The modular design supports future expansion or upgrades, ensuring maximum long-term investment value.

Insight into market trends and grasp the future of modified asphalt production plant

As road construction demands continue to escalate, high-performance modified asphalt is increasingly being used across a wide range of projects. From highways to airport, from urban arterial roads to roads in extreme climates, modified asphalt equipment is becoming a key tool for ensuring construction quality and efficiency. In this rapidly evolving market, understanding the current industry landscape and future trends not only helps companies plan their investments wisely but also enables them to seize opportunities for technological advancement and market expansion, ultimately generating higher returns and long-term value for their projects.

Current Market Landscape

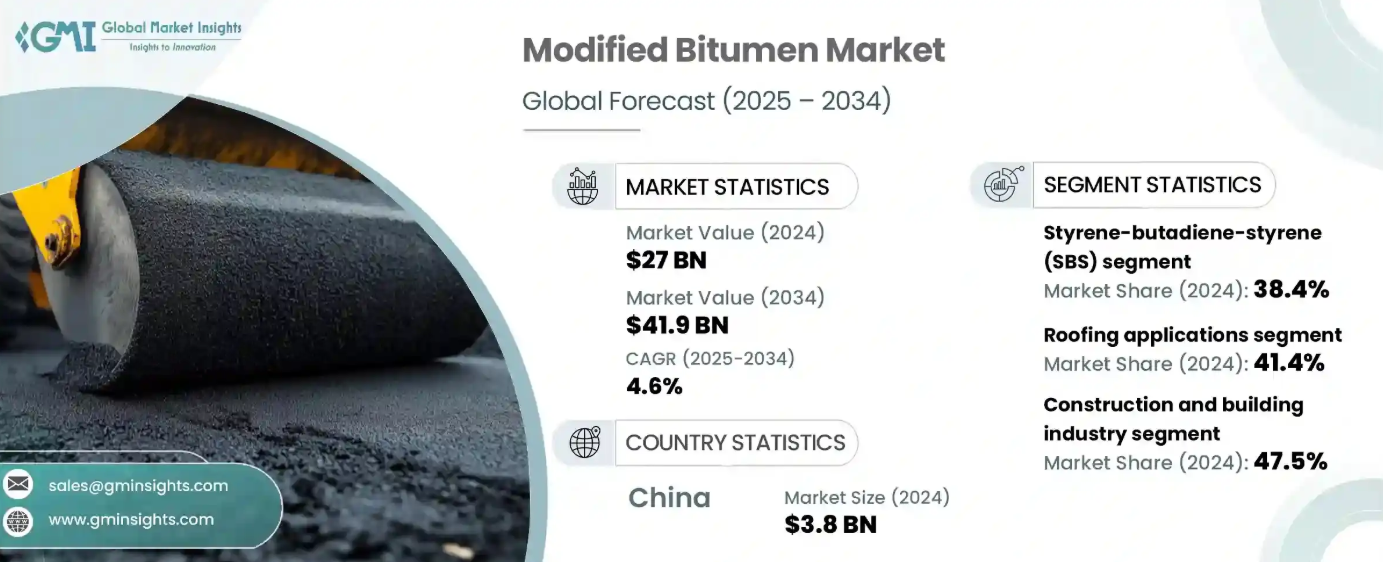

- Continuous Growth in Market Size: The global modified asphalt market reached US$27 billion in 2024 and is projected to reach US$41.9 billion in 2034 (CAGR of 4.6%).

- Clear Technology Leadership: SBS-modified asphalt holds a 60.4% market share, followed by rubber modifiers (such as crumb rubber) and epoxy resin-modified asphalt.

- Diverse Project Demands: Urban roads, bridges, airports, and highways all have varying performance, construction efficiency, and environmental requirements. This necessitates equipment that balances flexibility, capacity, and intelligent control.

Future Development Trends

High-Performance Nanocomposite Modified Materials

- Self-Healing Potential: Nanotube networks capture microcracks and conduct heat, enabling localized temperature rises to trigger asphalt flow and fill cracks, effectively extending the service life of the pavement.

- Multifunctional Applications: Anti-icing and anti-skid modifiers and conductive materials can melt snow and ice; photocatalytic TiO₂-modified asphalt decomposes NOx and VOCs, contributing to the construction of “carbon-negative” roads.

Green and Low-Carbon Process Innovations

- Low-Temperature Modification Technology: For example, USP low-temperature modified asphalt uses composite additives to lower the mixing temperature to 120-160°C (compared to the traditional 180-210°C), reducing energy consumption by 40% and carbon emissions by 65-85%, while also improving anti-rutting performance by 200%.

- Odor-Free and Environmentally Friendly Process: Waste tire rubber crumb modified asphalt is treated with a vulcanizing agent and a deodorizer, reducing benzopyrene emissions during construction by 90%, achieving “smoke-free and odor-free” operations.

Intelligent and digital production system

- AI-based optimization of mix proportions and quality control: An AI algorithm based on a multi-source database (RAP components and climate data) dynamically adjusts modifier dosage (with an error rate of <0.8%) to adapt to varying loads and climate conditions. RCA compounded dual modifiers utilize nano-dispersion technology to achieve real-time gradation optimization, improving high-temperature performance by 300%.

- IoT-based full-process monitoring: Infrared thermal imaging and laser particle size analysis track the mix status in real time, while a cloud-based platform provides early warning of quality deviations to ensure construction and production stability.

The modified asphalt equipment market is undergoing rapid development. From the widespread application of SBS and rubber modification technologies to the continuous innovation of intelligent, low-carbon, and functional materials, the entire industry is showing a trend of efficient and sustainable development. For every modified asphalt project, understanding the current market situation and future development trends not only helps companies plan equipment investments scientifically, but also allows for the proactive planning of construction processes and material management, ensuring efficient, stable, and cost-effective projects.

FAQs

Can modified asphalt production plant replace ordinary asphalt mixing plants?

Modified asphalt equipment is specifically designed for the production of SBS or rubber-modified asphalt. It can handle the uniform mixing of high-temperature, high-viscosity materials and modifiers. Its high-shear mixing and intelligent temperature control system ensure that the finished product meets high-standard engineering requirements.However, conventional asphalt mixing plants remain irreplaceable in the production of standard asphalt: their mature structure, stable production capacity, and simple operation make them suitable for large-scale traditional asphalt production. Both types of plants have their own advantages in terms of function and application scenarios. It’s not a simple substitution; choosing the right equipment based on project requirements maximizes construction efficiency and material performance.