Strategic Partner of Fortune Global 500 Companies

High-Precision Weighing System: Aggregate Error ± 0.5%, Powder and Asphalt Error ± 0.25%

Over 90% of early damage to asphalt pavements worldwide stems from unstable mixture quality, gradation deviations, inaccurate asphalt-aggregate ratios, and temperature segregation. These hidden defects often lead to serious problems such as rutting and cracking within a few years of a project’s opening.

Asphalt batch mix plant is the core weapon to end this persistent problem: each batch is independently and precisely metered, batch biaxial mixing is implemented, and the error is controlled within 0.3%, ensuring the mixture meets standards from the source.

A precise batch asphalt plant is often the watershed between a project’s initial compliance and its benchmark status. Whether your project is a rainy highway in Southeast Asia, a frigid national road in Central Asia, a heavy-duty mining road in Africa, Macroad asphalt batching plant can ensure your pavement remains like new for ten years, significantly reducing total life-cycle maintenance costs.

Asphalt Batch plant: In which scenarios is it indispensable?

A precise high-performance batch mix plant can elevate the quality of asphalt mixtures from acceptable to benchmark. But where does it truly shine? In the global wave of infrastructure construction, high-performance asphalt mixing plants have long been the preferred choice for high-standard road projects. According to data from Congruence Market Insights, the global batch mix asphalt plant market is projected to continue expanding at a CAGR of 3.5% from 2025 to 2032, and the share of asphalt batch plants are rapidly increasing—the reason is simple: more and more countries and regions are rejecting substandard road surfaces that are merely functional, and instead pursuing higher durability and environmental performance.

| Highway and Provincial Road Construction: | In highway projects in Southeast Asia (e.g., Indonesia, Vietnam), Central Asia (Kazakhstan), asphalt batching plants are the preferred choice. These projects often require extremely high asphalt-aggregate ratio precision and gradation uniformity to effectively resist high-temperature rutting and rain erosion. |

| Airport Roads and Aprons: | Large-scale airport expansions in the Middle East (Dubai, Saudi Arabia) and Africa (Ethiopia, Kenya) have stringent requirements for the asphalt mixture’s resistance to fuel erosion and heavy-load capacity. The independent testing of each batch of asphalt can meet the most stringent international standards such as FAA and ICAO. |

| Urban Arterial Roads and Municipal Road Renovation: | Projects such as old road renovation in Europe, urban renewal in Australia and New Zealand, and projects supported by North American infrastructure laws increasingly emphasize the mix proportions of different asphalt formulations. Batch mix asphalt can flexibly and quickly switch between special formulas, precisely controlling the ratio of mineral powder and additives. |

| Heavy-Duty Logistics and Port Roads: | In scenarios such as mining roads in Africa and agricultural transport corridors in Brazil, the road surface must withstand the constant pressure of heavy trucks. The higher mixing intensity of a batch type asphalt plant allows large-diameter aggregates to be fully coated with asphalt, significantly improving the fatigue resistance of the pavement. |

| Extreme Climate Environments: | From the Siberian highways and the Mongolian Plateau in Russia to temperatures exceeding 50°C in the Middle Eastern deserts, the intelligent and precise temperature control system of the batching plant for asphalt meets the extremely cold areas road construction environmental regulations while significantly reducing energy consumption. |

This is why global contractors often highlight the use of high-performance, compacted asphalt batch mixing plant as a technological advantage when bidding on projects. Macroad HPM mixing plants have been deployed in over 60 countries worldwide, helping clients deliver time-tested road surfaces from the equator to the Arctic Circle.

Which category does your next project fall into? Read on as we use real-world case studies to show you how asphalt batching plant machine have repeatedly transformed challenging projects into benchmark projects.

Macroad Asphalt batch plant solves construction problems

Malaysia client Building Confidence with the First Asphalt Batch Plant Investment

- Model: ALQ120

- Project Manager: The ALQ120 delivered stable performance and accurate mixing, giving us confidence in our first purchase.

ALQ80 Asphalt Batch Plant Stable Output Even in Mongolia Extreme Cold

- Capacity: 80tph

- Operations Supervisor: Even in sub-zero temperatures, the ALQ80 maintained stable production—a remarkable performance.

On-Site Training Ensures Kyrgyzstan ALQ80 Asphalt Batch Plant Fast Commissioning

- Capacity: 80tph

- Site Construction Manager: The on-site training helped our team master the operation quickly, speeding up project progress.

ALQ120 Achieved Reliable Mixing for Municipal Road Projects

- Project Location:Jamaica

- Quality Supervisor: Every batch of ALQ120 was consistent and stable, which greatly improved the reliability of our municipal works.

ALYQ90 Asphalt Batch Plant With Fast Relocation for Multi-Site Construction

- Capacity: 90tph

- Equipment Supervisor: The ALYQ90’s rapid relocation ability allowed us to progress multiple sites simultaneously.

Two core series asphalt batch plants to meet all scenario needs

We never think that one type of asphalt batch mix plant can be adapted to all projects. In particular, there are actually more branches under each type of project mentioned above. Therefore, based on 20+ years of project experience, Macroad has created two targeted asphalt batch plants for sale, from stationary to mobile asphalt batch mixing plants, covering different construction periods, sites and production capacity requirements:

ALQ series

Designed for long-term on-site and large-scale production projects, one batch type stationary asphalt plant is a prefect asphalt mixture factory, and stable output is its core label:

- High heating efficiency: The drying drum removes moisture from cold aggregate in the downstream mode. The wind rolled up from the center of the drum can ensure high thermal efficiency and accelerate the heating speed.

- High-precision weighing system: small weighing error, aggregate error within ±0.5%, powder and asphalt error within ±0.25%, and good finished material quality.

- Reliable and durable: mixing blades, hot aggregate silos, (finished product silos above 160) and other wear-resistant structures are upgraded, equipped with fault predictive maintenance technology, and key structural parts meet the discharge of millions of tons.

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

ALYQ series

Born for multi-plot construction and short-term projects, the magnetic building block design, quick-plug connectors, water, electricity and gas quick-plug connections and foundation-free installation provide the basis for mobile asphalt batch mix plant efficient 24-hour rapid transition and production :

- Intelligent operating system: Equipped with AI bee control system, fully automatic operation + intelligent early warning, support one-key switching of formulas, and also equipped with a mobile phone APP remote monitoring system, saving 50% of manpower.

- Efficient mixing and screening system: Boiling mixing + large channel screening patented design, efficiency increased by 15%, convenient maintenance, core components free of replacement for 5 years, and vibrating screen motor free of maintenance for 2000 hours.

- Precise metering system: AI automatic weighing, error as low as 1%, avoid waste, save about 80 tons of materials per day, equipped with efficient electronic calibration.

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

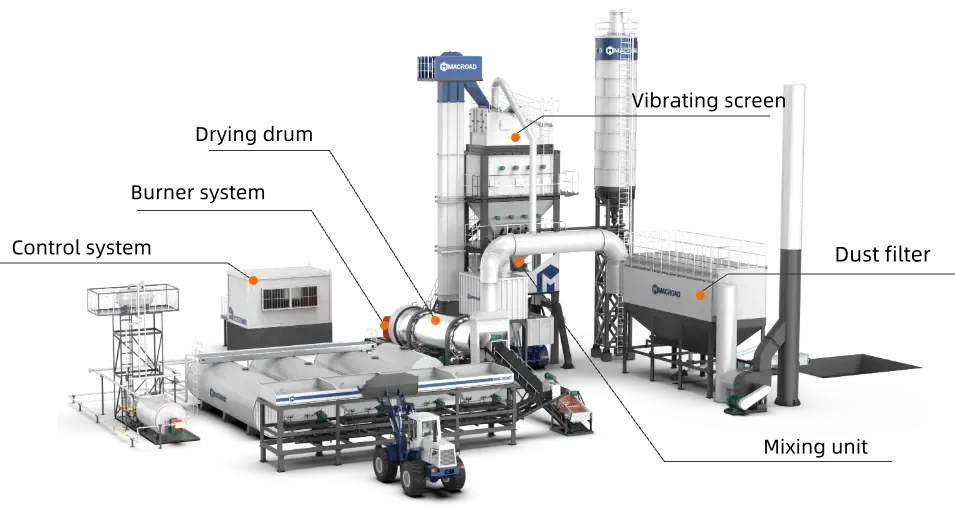

Coordination of core components of asphalt batch plant

How does an asphalt batch plant work? In the field of intermittent mixing, equipment is not simply a collection of parts, but rather a deep collaboration centered around the core logic of independent and precise processing of each batch of material. Macroad implements this concept into asphalt batch plant diagram, ensuring that the error across the entire chain from cold aggregate to finished product is close to zero.

Cold Aggregate Supply and Pre-treatment System

- Multi-bin Intelligent Storage: Simultaneously stores 3-6 different aggregate sizes, with automatic bin management, real-time material shortage warnings, ensuring continuous production and avoiding sudden shutdowns.

- Variable Frequency Precision Feeding: The conveyor belt automatically adjusts its feeding speed according to demand, reducing the risk of material blockage or interruption.

- High-Efficiency Counter-current Drying: Optimized counter-current drying cylinder + insulation layer design in asphalt batch mix plant process achieves rapid dehydration of aggregates, maintaining a stable moisture content of ≤0.5%, and increasing thermal efficiency by 12%, providing the cleanest raw material foundation for subsequent high-precision metering.

Precision Metering and Screening System

- Multi-stage Screening Device: A four-stage vibrating screen separates aggregates of different particle sizes, ensuring uniform particle shape, improving the stability of the final mixture, and eliminating the gradation drift common in continuous equipment.

- Independent High-Precision Weighing: Three independent asphalt batching plant components: weighing sensors for aggregates, mineral powder, and asphalt, dynamically compensating for errors controlled within ±0.5% for aggregates and ±0.25% for powders and asphalt, achieving precise proportioning.

- Fully Enclosed Metering Structure: Prevents dust spillage and material loss during weighing, ensuring stable and reliable weighing data.

Mixing and Temperature Control System

- Dual-Shaft Batch Mixing Host: A large-capacity mixing pot with high-wear-resistant alloy blades rotates the material 360°, achieving 100% asphalt coating and improving mixing uniformity.

- Intelligent Temperature Control: Real-time monitoring and automatic adjustment of mixing temperature, with temperature fluctuations controlled within ±3℃, preventing finished product quality fluctuations caused by overheating aging or low-temperature segregation.

- High-Load Durable Design: Upgraded wear-resistant structures in the mixing blades, hot aggregate bins, and finished product bins. Core components support million-ton-level discharge, reducing long-term operation and maintenance costs.

Environmental Dust Removal and Maintenance System

- Dual-Stage Dust Removal Structure: Cyclone + bag filter dual filtration, dust capture rate >99%, emission concentration below 50mg/m³, meeting environmental requirements of multiple countries.

- Pulse Automatic Cleaning: Regularly and automatically cleans filter bags and pipe deposits, ensuring dust removal efficiency and extending filter bag life by more than 2 times.

- Telescopic Dust Suppression Pipeline: Allows for ±3cm installation error, enabling complete connection within 24 hours, reducing installation difficulty and time costs.

Finished Product Storage and Scheduling System

- Constant Temperature Insulated Silo: Double-layer structure effectively maintains stable discharge temperature, with temperature decay

- Heated Discharge Port: Continuous heating prevents port blockage, ensuring smooth discharge.

- Intelligent Scheduling Control: IoT material level sensors + cloud-based real-time scheduling automatically matches paver progress, reducing transport vehicle waiting time by over 30%.

Intelligent Control and Remote Monitoring System

- One-Button Start/Stop Control: Simplifies traditional 50-step operation to one-button start, improving production efficiency.

- Multi-Mode Operating Interface: Three control methods—computer, touchscreen, and physical buttons—to meet different operating habits.

- IoT Remote Monitoring: Real-time data collection of equipment operating status, automatic maintenance reminders and fault warnings, supports remote parameter adjustment, reducing downtime risk.

Asphalt batch plant vs drum plant

Of course, for asphalt mixing plants, the importance of another type—the asphalt drum mixing plant—cannot be ignored. But is batch mixing always better than drum mixing? The answer is: no single type of equipment is suitable for all projects.

If we compare the two types of asphalt plants to chefs, the drum mixing plant is like a fast-food chef on an assembly line, prioritizing efficiency; the batch asphalt plant is like a chef preparing delicate cuisine, pursuing precision and stability. The differences between the two will be magnified in the details of project acceptance. The table below will help you quickly understand difference between batch mix plant and drum mix plant:

|  |  |

|---|---|---|

| ALQ series batch mix asphalt plant | Model | ALT series drum mix asphalt plant |

| Fixed vertical layout, multi-module independent structure, large footprint | Structure Type | Fixed drum integrated structure, integrated drying and mixing functions, occupies a small space |

| Intermittent production (batch cycle operation) | Production Process | Continuous production (continuous feed of raw materials, continuous output of finished products) |

| Multi-stage aggregate proportioning control | Control System | Continuous flow monitoring with temperature linked control |

| Large volume batch production for multiple recipe switching | Capacity Characteristics | Continuous discharge without interruption, suitable for long-term supply of a single recipe. |

| High formulation flexibility; Excellent mix uniformity; Suitable for high quality asphalt | Equipment Performance | Higher thermal efficiency; Single quality asphalt; Compact structure and small footprint |

| Twin-shaft forced mixing, aggregate coating rate >98% | Mixture uniformity | The drum rotates and stirs, and waste is likely to appear locally |

| Comprehensive municipal roadway projects with multiple types of mix requirements | Project Adaptability | Single-formula centralized feeder for large-scale municipal road projects. |

| batch mix plant price is relatively high (precision metering and mixing systems are expensive) | Initial investment | drum type asphalt plant price is relatively lower (simplified structure, saving 20-30% for the same tonnage) |

If your project frequently requires formula modifications, pursues the highest possible pavement quality, and meets stringent international standards—choosing a batch mix plant is almost a no-brainer.

If your project primarily involves large-volume base or subbase courses, has a fixed formula, and faces tight budgets and space constraints—a drum mix plant is often more cost-effective. Globally, over 60% of highway surface courses still use asphalt batching plant, while 80% of rural roads and base courses are handled by drum mix plant—this is precisely the most rational choice in the market.

Why Asphalt Plant Theoretical vs. Actual Output Differs

Many owners only look at the 100t/h asphalt batching plant capacity when purchasing it, only to find after delivery that it can only produce 600-700 tons of material per day, directly causing project delays and fines.

The capacity of an asphalt plant is never a single number, but rather the result of the entire system’s coordination—an error in any link can halve the actual output. This is why, with the same 100t/h capacity, some projects easily produce over 1000 tons per day, while others struggle to reach only 600 tons. Understanding these factors beforehand will allow you to avoid capacity traps during the selection, operation, and maintenance phases.

Raw Material Pretreatment Efficiency (Highest weighting, accounting for 30%)

- Cold Aggregate Moisture Content: For every 1% increase in moisture, drying time increases by 8–12 seconds, and overall plant capacity decreases by 10–15%.

- Drying System Thermal Efficiency: Low thermal efficiency directly reduces hourly dry aggregate output by 8–12 tons.

- Cold Aggregate Silo Feed Continuity: A single blockage or shortage results in a 45-second loss per cycle, accumulating to a daily loss of 30–50 tons.

- High-Efficiency Drying System: Optimized burner air-fuel ratio + low-resistance cylinder structure achieves higher drying capacity with the same fuel.

- Intelligent Moisture Content Compensation Algorithm: Automatically adjusts flame power and speed based on aggregate moisture content, ensuring the drying section always operates at full capacity.

- Anti-Blocking Cold Aggregate Silo Structure: Large-angle silo, reinforced buffer grid, and variable frequency feed belt reduce the probability of blockage and ensure continuous feed.

Screening and Batching Accuracy (Weight: 20%)

- Vibrating Screen Screening Efficiency: Screen blockage or incomplete grading can lead to material loss in hot silos, resulting in a loss of 8–15 tons per hour.

- Metering System Response Speed and Compensation Accuracy: Slower drop compensation leads to longer mixing cycles, resulting in daily output variations of 80–120 tons.

- Raw Material Gradation Fluctuations: When gradation is unstable, the system automatically reduces speed to ensure stable asphalt coating and quality, passively reducing production capacity by approximately 15%.

- Large-Channel Vibrating Screen Design: Reduces blockage through a large-channel structure, improving screening efficiency by 10–15% and achieving 2000 hours of maintenance-free operation.

- AI Precision Metering System: Employs a high-speed response module + dynamic drop compensation, achieving a compensation error of ≤±0.25%, enabling precise metering and reducing mixing cycle waiting time.

- Gradation Fluctuation Prediction Algorithm: Real-time monitoring of raw material particle size changes allows for early intervention and batching adjustments, preventing speed reduction due to system protection.

Mixing Cycle and Main Unit Performance (Weight: 20%)

- Single-pot mixing time: The standard mixing time is 45 seconds, which is the most critical factor affecting output.

- Mixing pot discharge speed: Traditional flap gates require 6-8 seconds, directly impacting overall process efficiency and discharge rhythm.

- Main unit full-load capacity: Unstable full-load performance leads to automatic system speed reduction, making it difficult to achieve the nominal output value.

- Optimized strong-duty mixing main unit structure: Improved mixing efficiency, optimized mixing trajectory, and extended blade wear life reduce the standard mixing time to 35-38 seconds, improving mixing efficiency.

- High-speed pneumatic discharge gate: Enables rapid discharge in 3 seconds, saving 4-5 seconds compared to traditional flap gates, significantly shortening the single cycle.

- Main unit constant load operation design: Automatically balances temperature, viscosity, and load fluctuations, preventing system speed reduction and maintaining high output.

Finished Material Storage and Transportation Coordination (Weight: 10%)

- Insufficient finished material silo capacity: When transport vehicles are waiting for materials, asphalt mixing plants are forced to operate intermittently, potentially halving their actual production capacity.

- Discharge height and unloading speed: Insufficient discharge height leads to queues; a 1-second delay in unloading equals a loss of 2-3 tons per hour.

- On-site dispatch matching: If transport vehicle waiting time exceeds 5 minutes, daily production capacity loss can reach 20%.

- Large-capacity insulated finished material silos: Maintain continuous discharge and reduce downtime losses due to insufficient vehicle dispatch.

- High-level rapid discharge structure: Shortens vehicle queuing time and improves overall transportation efficiency by 10%-15%.

- Dispatch auxiliary system: Real-time monitoring of vehicle entry and exit, enabling intelligent queuing and optimized discharge rhythm.

Ambient Temperature and Climate Factors (Weight 10%)

- Ambient Temperature: For every 10°C decrease in ambient temperature, combustion energy consumption increases by 8–12%, drying time is prolonged, and production capacity decreases by 8–10%.

- Low Oxygen Levels at High Altitudes: Combustion efficiency decreases by 15%, requiring a booster burner to restore performance.

- Wet Raw Materials During the Rainy Season: Moisture content increases from 3% to 8%, causing production capacity to drop directly from 100t/h to 65–70t/h.

- Cold Region-Specific Heating System: The mixing unit, asphalt pipelines, and finished product silo are all insulated, and have been verified in projects in Mongolia and Kazakhstan.

- Booster Burner: The equipment is equipped with a booster burner, suitable for high altitudes of 2000–3500m, maintaining a stable flame and high drying efficiency, solving the combustion efficiency reduction caused by insufficient oxygen.

- Rainproof Wet Material Management System: AI detects weather trends, provides early warnings, and automatically adjusts drying and batching strategies.

Operation and Maintenance Level (Weight: 10%)

- Operator Proficiency: Differences in operating speed between skilled and novice operators can lead to a 30% difference in daily output.

- Preventative Maintenance Frequency: Uncleaned screens and untimely blade checks can silently extend mixing time by 20%.

- Automation Level: Higher levels of automation minimize the negative impact of human factors on production capacity.

- Three Operating Modes: Utilizes computer, touchscreen, and manual operation modes to accommodate different operating habits, allowing even beginners to quickly learn and operate stably.

- IoT Intelligent Operation and Maintenance System: Automatically reminds users to clean screens, calibrate, and inspect vulnerable parts, preventing hidden production reductions due to neglected maintenance.

- AI Adaptive Production Optimization: Automatically adjusts flame power, batching speed, and discharge rhythm to maintain optimal production efficiency.

The actual capacity of an asphalt batch plant depends 70% on the equipment itself and 30% on how you use it. By managing these factors well, a nominal capacity of 100 t/h can easily become an actual capacity of 100 t/h or even higher.

Macroad means guaranteed your project success

With so many asphalt batch mix plant suppliers on the market, why are more and more contractors worldwide ultimately choosing Macroad? The answer is simple: Macroad offers its clients not just a piece of equipment, but a complete guarantee for project implementation.

Macroad deeply understands the decisive role of asphalt batch mixing plants in project quality. For over two decades, our equipment has been operating reliably in more than 500 critical projects, including highways, airport roads, and municipal roads. Choosing Macroad means more than just selecting asphalt batch plant manufacturers; it means choosing a professional partner who ensures project stability and control, and guarantees reliable and solid road quality.

Macroad’s R&D System Focused on Batch Mixing Processes

Many brands aim for universality when developing mixing plants, but Macroad’s R&D logic has been built around the asphalt batching plant process from the very beginning. Batch mixing demands higher standards: more stable particle size distribution, more precise temperature control, more uniform asphalt coating, more thorough mixing intensity, and less batch-to-batch variation. Macroad’s technological advantage stems from its focus on solving the key bottlenecks of the batch mixing process:

- Data-driven batch control: We optimize not the mechanical structure, but the three most crucial data points in asphalt batch plants production: changes in aggregate moisture content per batch, real-time asphalt compensation, and mixing energy input. Introducing AI algorithms allows for dynamic correction of these three factors, ensuring consistent quality across different batches.

- Optimized mixing structure design: Macroad’s main mixer blade angle, wheelbase, and circulation path are optimized through simulation calculations, rather than using generic templates. This directly improves: stability, flow value, rutting performance, and durability.

- Temperature control system deeply understanding material behavior: Changes in asphalt viscosity across different temperature ranges directly affect the batch mixing effect. Macroad’s intelligent temperature control system automatically adjusts drying, heating, and mixing temperatures by real-time data collection of material temperature, ambient temperature, and mixing energy.

- Multiple patents form a closed-loop process: Macroad’s patented technologies are not merely decorative, but serve the stability of the batch mix production chain: pipeline structures reduce asphalt temperature loss, modular design improves maintenance efficiency, and a highly integrated control architecture enhances coordination precision. These technologies ensure that every link in the batch mix production chain is accountable for the final quality.

Engineering Service System for Road Projects

A batch asphalt plant is not just a piece of equipment sold and done; it’s a system requiring continuous calibration, real-time mix optimization, and long-term stable operation. Any downtime, accuracy drift, or temperature runaway can render an entire truckload of mix unusable. Macroad’s service value lies in our understanding not only of the equipment but also of the working pace, material properties, and construction windows of road engineering projects. We will make asphalt batch mix plant price truly worth it.

- Our service team possesses a deep understanding of the process: All of Macroad’s service engineers have undergone specialized training in asphalt batch mix plant process, enabling us to solve problems that truly affect mix quality, such as: how to adjust the mixing cycle based on aggregate moisture content; how to adjust the asphalt temperature profile in high-altitude areas, etc.

- Localized spare parts and on-site service: Batch mix asphalt mixing plants are batch-driven; once a plant stops, the entire project chain is forced to halt. To this end, Macroad has established local spare parts warehouses, regional service centers, and rapid response teams in Malaysia, the Philippines, Indonesia, Uzbekistan, and Russia.

- Full-cycle project involvement: The Macroad team participates in the entire project setup phase, including project planning, equipment layout design, installation and commissioning, operator training, capacity ramp-up guidance, and production optimization during the project period, ensuring the stable operation of the mixing plant.

A Strict Delivery System Adhering to Construction Milestones

Most asphalt plant suppliers‘ delivery ends here: equipment installation complete, ready for operation. Macroad’s delivery standard is: the first batch of mix must be qualified. To achieve this standard, we have established an engineering-based delivery system:

- Early Intervention in Foundation Construction and Site Planning: Batch mixing plants are extremely sensitive to screening height, hot material reflux, and metering drop. Macroad will ensure through upfront technical support: hot material will not clog, metering will not drift, proportions will not be disordered, and production capacity will not be limited by layout.

- Triple Calibration: The batch mix asphalt plant production chain is a precision system; equipment must be recalibrated upon arrival at the site. Macroad will perform on-site calibration: precise proportioning, temperature control curve adaptation to local climate, mixing energy calibration, ensuring road projects can be produced according to specifications.

- First Batch Mix Validation: For the first batch, we work with the customer to verify various indicators such as stability, flow value, porosity, and rutting index, ensuring the mix truly meets high-grade road requirements.

- Continuous optimization during operation: Every piece of data in the production process, such as temperature, moisture content, stirring cycle, and utilization of recycled powder, will be used to optimize and continuously improve efficiency and reduce costs.

Macroad’s value lies not in equipment specifications or a single technology, but in making every batch of mix controllable, ensuring equipment runs continuously at critical moments, guaranteeing road quality and construction progress, and making project profitability predictable.

Macroad doesn’t just sell an asphalt batch plant; it provides a stable, reliable, and sustainable batch mix production system for your road projects. We understand that a batch mix plant is more than just equipment; it determines whether a project can be delivered on time and whether the road can withstand heavy loads and the test of time. From technical design and capacity utilization to service response and project implementation, Macroad always adheres to the core principles of real capacity, stable output, and long-term reliability.

Now is the best time to make your project more secure, controllable, and worry-free. Contact us now; an email or a phone call can transform your batch mix project from uncertain to predictable.