Continuous operation, stable and controllable production capacity

Thermal efficiency upgrade, significant energy saving and consumption reduction

When you stand at the starting point of a project, you are faced with a rugged mountain road or an unfinished rural road. Challenges are coming. How to choose equipment? How to divide the budget? Is there enough time? Every project is not just a simple construction, but a systematic test of progress, quality and cost.

At this time, a equipment that can be put into production quickly, flexibly deployed, simplified in structure, and easy to control can really keep up with your construction rhythm and help project construction. Asphalt drum mix plant are repeatedly selected, verified and recognized in such needs.

Applicable scenarios of drum asphalt mixing plant

Because of the many changes on the construction site, the tight construction pace and limited resource allocation, more and more project managers are starting to choose equipment based on reality, and choose drum mix plant with simple structure, continuous discharge and stable operation.

Under this demand trend, drum asphalt mixing plants are being continuously recognized by the global market. According to asphalt drum mix plant industry research data, the global drum mix asphalt plant market has reached US$1.5 billion in 2024, and is expected to grow to US$2.5 billion by 2033, and will maintain a compound annual growth rate (CAGR) of 6.0% between 2026 and 2033. Behind this growth momentum is the real demand for continuous, reliable and flexible drum asphalt mixing plant for more and more infrastructure projects.

So what scenarios are drum asphalt mixing plants used in?

| Rural road/branch line expansion: | short construction period, frequent transfer, the rapid deployment characteristics of mobile asphalt drum mixing plants are highly adaptable. |

| Local municipal roads/industrial park road repair: | high requirements for equipment installation speed and discharge continuity, ALT/ALYT series can be installed and used immediately. |

| Remote mountainous areas/resource-limited areas: | simple operation, stable operation, and no reliance on complex engineering personnel system. |

| Emergency repair/emergency engineering: | Bridges have extremely high requirements for the fast discharge and flexible response, it is an emergency asphalt drum plant often used by many local governments or contractors. |

Although these usage scenarios are different, they have in common: extremely high requirements for equipment efficiency, flexibility and reliability, which is the core advantage of drum asphalt mixing plants.

Asphalt Drum Mix Plant in Real Project Cases

High cost-effectiveness ALT40 debuts in Fiji, driving down road construction costs

- Productivity: 40 t/h

- Project Details: The ALT40 in Fiji delivers efficient continuous mixing with precise temperature control, slashing operational costs. Its reliable performance ensured on-time project completion, exceeding quality expectations for large-scale road builds.

From blueprint to smooth road! ALT80 wholeheartedly safeguards the new journey of rural road construction in Brazil

- Productivity: 80 t/h

- Feedback from project lead: Recommended by an old client, the ALT80 asphalt drum mix plant impressed Brazil’s rural road project. Its flawless operation ensured smooth construction, with the local firm praising its quality—validating trust in Macroad’s equipment.

Tailor-made with remarkable effectiveness! ALT60 has been smoothly commissioned in Kyrgyzstan

- Productivity: 60 t/h

- Operator Feedback: The ALT60 in Kyrgyzstan shines with smart controls for precise mixing and temp settings. Its energy-saving design cuts costs, while consistent output speeds workflows—truly a game-changer for the project.

Conquering slow moves! ALYT100 zips across Ecuador, keeping roadwork non – stop

- Productivity: 100 t/h

- Feedback from engineer: The ALYT100 mobile asphalt drum mix plant’s flexibility excels in Ecuador: narrow paths and rugged terrain pose no challenge. Its modular design enables transport ease, with assembly/debugging in hours—slashing prep time, reducing downtime, and ensuring on-schedule, cost-controlled progress.

ALYT120 in Dominican Republic: Tropical-Ready Design Sustains Coastal Road Progress

- Productivity: 120tph

- Engineer’s Observation: The ALYT120 thrives in Dominican Republic’s high humidity and coastal salt air, with corrosion-resistant components. Its 120t/h output stays consistent, even in 35℃+ heat, cutting maintenance by 25% versus standard models—critical for coastal road upgrades.

ALT120 in Guatemala: Community-Centric Efficiency Boosts Local Connectivity

- Productivity: 120tph

- Project Coordinator’s Note: The ALT120 asphalt drum mix plant accelerates Guatemala’s rural-urban road links, with 120t/h output reducing construction time by 30%. Its low noise operation minimizes disruption to nearby villages, while local technician training from Macroad ensures long-term sustainability—strengthening community trust.

Macroad Asphalt Drum Plant – Born For Your Projects

We know that construction scenarios are never the same. Sometimes you need to work continuously in a fixed site and ensure a stable supply of materials; sometimes you need to move between multiple construction sites, and the flexible movement of equipment directly affects the construction period. asphalt drum mix plant manufacturer – Macroad’s two types of asphalt plant are designed based on these real needs.

ALT series asphalt drum mix plant

If your project is carried out at a fixed site, such as industrial park road construction or urban trunk road renovation, and requires a stable output of asphalt day after day, the ALT series stationary asphalt plant will be your reliable partner with the help of continuous production technology.

- Capacity: 20-100 tph

- Power Fuel Oil: 34-170kw

- Asphalt Temperature: 120-180℃

- Dust Filter: Bag dust filter

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

ALYT series asphalt drum mix plant

If your work rhythm is to finish one project and then immediately move on to the next one – such as rural branch line construction and emergency repairs in multiple locations, the ALYT series mobile asphalt plant for sale can save you a lot of trouble and quickly transfer to production within 48 hours, allowing you to efficiently advance scattered projects.

- Capacity: 20-100 tph

- Power Fuel Oil: 34-170kw

- Asphalt Temperature: 120-180℃

- Dust Filter: Bag dust collector / water dust collector

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

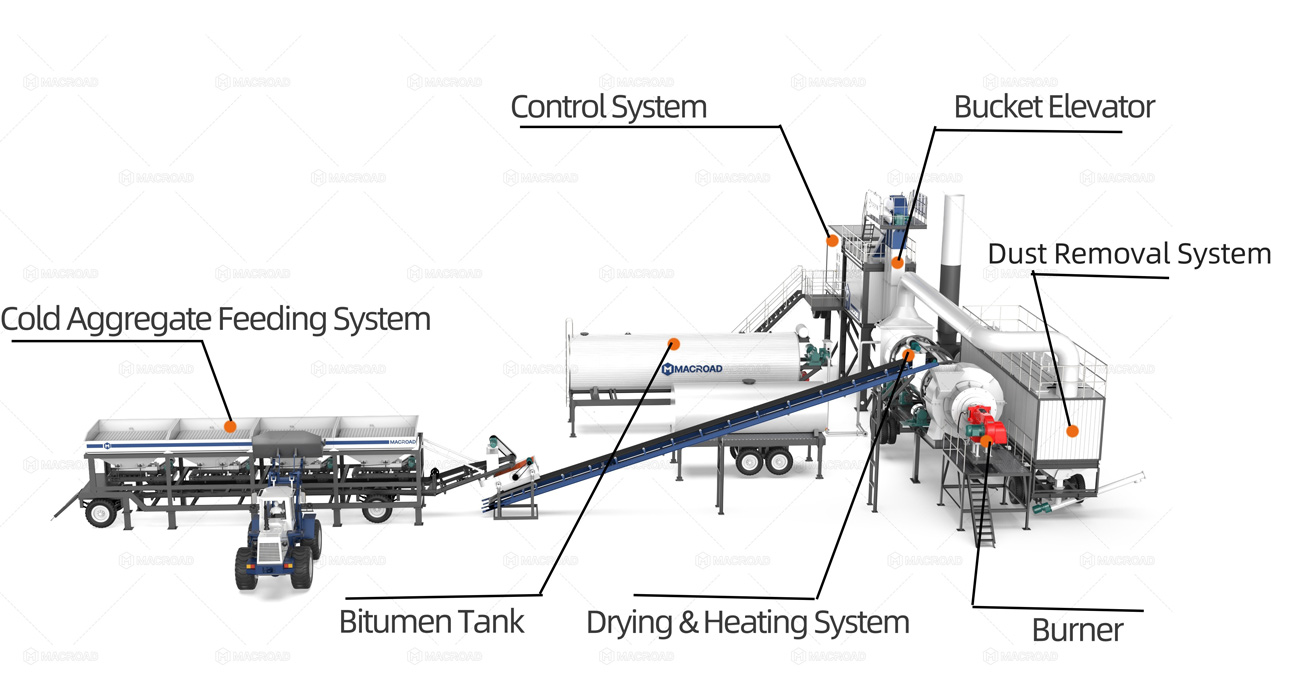

Six core systems of Macroad Asphalt Drum Mix Plant

Whether it is the continuous operation of the stationary ALT series or the flexible transfer of the mobile ALYT series, the stability and efficiency of the equipment are inseparable from the coordinated support of the six core systems. These systems perform their respective functions and are closely linked. From raw material input to finished product output, every step is precisely controllable. Let’s take a look at them one by one to see how they work together to ensure smooth and reliable asphalt production:

Cold material supply system

- Core function: Provide stable and continuous raw material supply for subsequent processes.

- Design highlights: Equipped with 4-6 cold material supply bins, it can store more stones of different specifications and reduce downtime caused by untimely raw material replenishment; the conveyor belt accurately delivers materials according to the preset ratio to ensure that the amount of raw materials entering the next link is stable and controllable.

- Actual value: Avoid material shortage and material interruption risks from the source, lay the foundation for continuous production, and allow subsequent systems to not worry about fluctuations in raw material supply.

Drying and heating system

- Core function: Dry the aggregate and heat it to a process temperature of 120-180℃.

- Design highlights: The integrated drying drum is equipped with a dual-fuel system (diesel/natural gas can be flexibly switched), which reduces energy costs by 25% compared with a single-fuel system; the optimized heat conduction structure increases heat utilization by more than 30%, reducing energy waste.

- Actual value: While efficiently removing moisture from the aggregate, the heating temperature is accurately controlled, taking into account energy consumption and process requirements, so that the aggregate state fully meets the subsequent mixing standards.

Weighing system

- Core function: Accurately measure the amount of hot aggregate, powder and asphalt to ensure that the ratio meets the formula requirements.

- Design highlights: Adopt dynamic weighing compensation technology, aggregate weighing error ≤±0.5%, powder/asphalt error ≤±0.25%; with automatic weighing function, real-time correction of small deviations.

- Actual value: fundamentally avoid manual ratio errors, ensure the accurate and stable composition of each batch of mixtures, reduce raw material waste, and ensure the consistency of finished product quality.

Mixing system

- Core function: Evenly mix the heated aggregate, powder and asphalt to form a qualified asphalt mixture.

- Design highlights: Continuous mixing technology is used to ensure stable discharging and improve mixing uniformity; the blades and linings are treated with wear resistance to reduce maintenance downtime.

- Actual value: The production capacity covers 40-160 tons/hour, which is suitable for projects of different scales, while ensuring the stability of the quality of the finished material and reducing the risk of rework.

Dust removal system

- Core function: Filter dust in the production process, meet environmental protection standards and achieve resource recovery.

- Design highlights: Integrated pulse bag dust removal device, dust emission ≤30mg/m³, in line with global environmental protection standards such as EU CE; 95% of fine powder can be recycled and reused and put back into production.

- Actual value: It not only avoids the risk of environmental fines, but also improves the utilization rate of raw materials. A single set of equipment saves 15%-20% of raw material costs annually, taking into account both environmental responsibility and economy.

Control system

- Core function: Coordinate and control the operation of each system, simplify operation and ensure stable production.

- Design highlights: Equipped with PLC intelligent temperature control system, real-time monitoring of drum temperature and parameters of each link

- Actual value: Lower the operating threshold and reduce human errors; support 24-hour continuous production monitoring, avoid downtime risks in advance, and keep the equipment in efficient operation at all times.

He spent 100,000$ for asphalt drum mix plant, but sold it after three months

After the introduction of the equipment performance of the drum asphalt mixing plant, you may have a preliminary understanding of the technical structure of this type of equipment. But whether a piece of equipment is suitable for your project is not only about the parameter table, but also depends on whether it really fits your project. Because, if the wrong model is chosen, it will not only waste money, but also miss the best window period of the entire project.

We once served a customer from West Africa. When he started a local provincial rural road project, he hurriedly purchased a set of equipment, and the total asphalt plant cost was 80,000 US dollars higher than the market average price, but he did not really use it in the project for more than three months. The reason is that the equipment has too large capacity, too high energy consumption, and too complicated transportation and installation, which has caused his project team to be unable to put it into production, and the project progress has been repeatedly delayed.

In the end, he had to sell this seemingly advanced equipment to others at a discount, and look for a suitable solution again with regret. This is not an isolated case.

In the process of contacting more than 500 project customers, as asphalt drum mix plant exporter, we found that equipment selection is almost one of the links that customers are most likely to ignore, but also the most likely to regret.

Therefore, asphalt drum mix plant selection is never a math problem of capacity + price. You are faced with construction period, site, budget, manpower, maintenance… Each variable can affect the final result, so before choosing equipment, ask yourself a few key questions with us:

How big is your asphalt drum mix plant project and what is the demand for material supply?

If you need to supply materials for a large or medium-sized project for a long time, and produce hundreds of tons every day, and pursue production capacity and stability, then you can consider equipment solutions with slightly higher production capacity.But if you are supplying materials for multiple scattered projects, the construction period is uncertain, and there is even the possibility of suspension in the middle, then it is more important for the asphalt drum mix plant to be able to start quickly and be flexibly relocated.

The equipment is not the bigger the better, but it must keep up with your construction pace.

During the entire project process, is it mainly flat land or mountain roads?

Different terrains have very different requirements for the stability and mobility of equipment:

- If there are more flat lands and fixed sites (such as industrial parks around cities and large infrastructure construction sites), basic roller stations are more suitable – the structure is stable, maintenance is more convenient during long-term use, and materials can be continuously and stably supplied;

- If there are many mountainous roads and it is necessary to switch between multiple scattered construction sites (such as rural road expansion and mountain road repair), mobile roller stations are preferred: compact size, high integration, no extra manpower is required for disassembly and assembly, more than half of the time can be saved during transfer, and delays in construction due to complex terrain can be avoided.

Is your material source stable? Do you have your own material yard or rely on external transportation?

Are the transportation conditions at the construction site for asphalt drum mix plant complicated?

This is directly related to whether the equipment transfer is smooth:

- If it is in the suburbs of the city, the transportation road is flat (such as direct provincial and county roads), and the transportation conditions are loose, you can choose slightly larger equipment according to the production capacity requirements – there is no need to worry about transportation obstructions, and installation is more convenient;

- If it is in a remote mountainous area, the road conditions are poor (such as narrow roads, steep slopes, muddy roads), and the terrain is uneven, the transfer friendliness of the equipment must be given priority: whether the size is suitable for local transportation vehicles (such as whether it can pass narrow bridges and tunnels), whether it comes with an integrated chassis (reducing on-site assembly), and whether the installation has low requirements for site flatness (such as tower-free design).

After all, no matter how good the equipment parameters are, it is useless if it cannot be transported to the construction site and installed.

Are you sensitive to fuel costs? Do you want to support multiple fuel switching?

Are the environmental protection requirements high at the project site? Is there a risk of dust nuisance?

Three Return Logic for Asphalt Drum Mix Plant

We have seen too many customers struggling when purchasing: When can they really make back the money they spent? In fact, the payback speed of asphalt drum mix plant is never a simple calculation of equipment price ÷ project profit – the key lies in whether it can keep up with the pace of your project, whether it can adapt to your team, site, and construction period.

Just like the same tool, the value it plays in different hands is very different. Whether it is a startup team that has just started, a construction party that needs to quickly advance the project, or an experienced industry team, their respective project rhythms, financial conditions, and team capabilities are different, and the logic of payback is naturally different.

First-time business customers: With a limited budget, every penny must be spent wisely

When entering the road construction industry, financial constraints are the norm. Many customers tend to only look at the price of equipment in the early stage, thinking that saving money is the beginning of profit. But the reality is often: choosing equipment from small factories for low prices, the equipment has low thermal efficiency, high fuel consumption, and frequent problems with wearing parts, resulting in repeated project shutdowns and delays. Not only can you not make money, but it will slow down the development of the entire business.

Macroad has seen too many such cases. We suggest: don’t rush to get it all done in one go, get the project running first, and then develop it. Starting with a small basic model (such as the ALT series), gradually upgrading in the later stage, controlling costs, and steadily expanding is a more reliable way to get back to the original cost.

Problems faced:

- New to the industry, lack of construction experience and industry judgment

- Limited funds, hoping to reduce the risk of initial investment

- Easy to choose low-quality asphalt drum mix plant due to price sensitivity

Common pitfalls:

- Choose equipment from small factories for low prices, resulting in high fuel consumption, frequent failures, and difficulty in advancing the project

- Blind pursuit of one-step completion, too large equipment leads to high financial pressure and low utilization

Macroad’s payback strategy:

- Recommend 40-80 tons/hour ALT series asphalt drum mix plant basic equipment to meet the needs of initial projects

- Support later modular upgrades (intelligent temperature control, dual fuel, etc.), and the upgrade cost is only 20%-30% of new equipment

- Overall control of initial costs, so that the equipment can truly participate in the project to create revenue before upgrading and expanding

There is a project but no technical team: Don’t let equipment debugging slow down the pace of payment collection

Although some customers have won the project, the construction team is not mature yet and lacks professional equipment operators. At this time, if the equipment has frequent problems during installation and debugging, it may miss the construction window, causing delays, breach of contract and loss of profits.

We recommend that such customers give priority to brand asphalt drum mix plant with convenient debugging and comprehensive after-sales service. Macroad’s mobile and stationary equipment provide 24/7 after-sales service to ensure your project goes smoothly.

Problems faced:

- The project has been obtained, but the team is not familiar with the operation of asphalt equipment

- Highly dependent on the technical support and training of the asphalt plant manufacturer

- High requirements for equipment delivery cycle and ease of operation

Common pitfalls:

- Purchase of assembled equipment, repeated problems in on-site commissioning, delaying production

- People arrive but cannot operate the equipment, inadequate training affects the progress of the project

Macroad’s payback strategy:

- Provide an integrated delivery solution: installation and commissioning are all completed by the original factory team

- Provide free training to help the team quickly master equipment operation and ensure that the project is put into production and completed on time

- After-sales response is not disconnected: equipped with 24-hour remote technical support to reduce downtime losses, so that the project will not be stopped, advance quickly, and collect payments more promptly.

Senior successful bidders: Pursue efficiency, but also pursue capacity matching

Experienced customers with stable projects often tend to purchase equipment with large capacity. However, if the equipment capacity is much higher than the actual demand, it will not only fail to improve efficiency, but will bring higher energy consumption and operation and maintenance costs, increase idle risks, and cause inefficient operation.

Macroad’s advice is: Don’t blindly pursue bigger and better, but pursue just right. We will develop the optimal capacity matching solution based on the characteristics of your project, so that the equipment can operate efficiently, reduce waste, and quickly return on investment.

Problems faced:

- Mature team and multiple projects in hand

- Stable projects, but fluctuating capacity requirements, such as centralized feeding in the early stage and decentralized repairs in the later stage

- Focus on equipment operation efficiency and discharge capacity

Common pitfalls:

- Choose large-capacity equipment for safety, but the daily utilization rate is less than 60%

- High energy consumption and low utilization increase operating costs and extend the payback period

Macroad’s payback strategy:

- Provide dynamic capacity matching solutions: Comprehensively consider the average demand of the project, construction rhythm and later changes, recommend the most suitable equipment for you, and take into account the peak feeding in the early stage and flexible repairs in the later stage

- Intelligent low-consumption mode: Automatically switch to low-power state when the equipment is idle, reduce idling energy consumption by 30%, and save 80,000-100,000 fuel costs annually;

- Improve equipment utilization, reduce unit cost by 15%, significantly shorten the payback period, and ensure maximum profit margin

The value of a drum asphalt mixing plant lies not only in its technical parameters, but also in whether it can truly adapt to the rhythm of your business development and create sustainable profits for you. Macroad not only sells equipment, but we also provide a complete set of full-cycle solutions from selection strategy to payback path. We understand the real concerns of each type of customer, and we also know how to use the actual output of the equipment to help you win back your investment. Your project is progressing smoothly and the benefits are realized faster, this is the meaning of the asphalt drum mix plant.