Strategic Partner of Fortune Global 500 Companies

Intelligent Operation, Efficient Production

If you are constructing a high-grade highway, airport access road, or a major urban thoroughfare that will withstand years of heavy traffic, then you know perfectly well that the quality of the asphalt mixture determines the road’s lifespan.

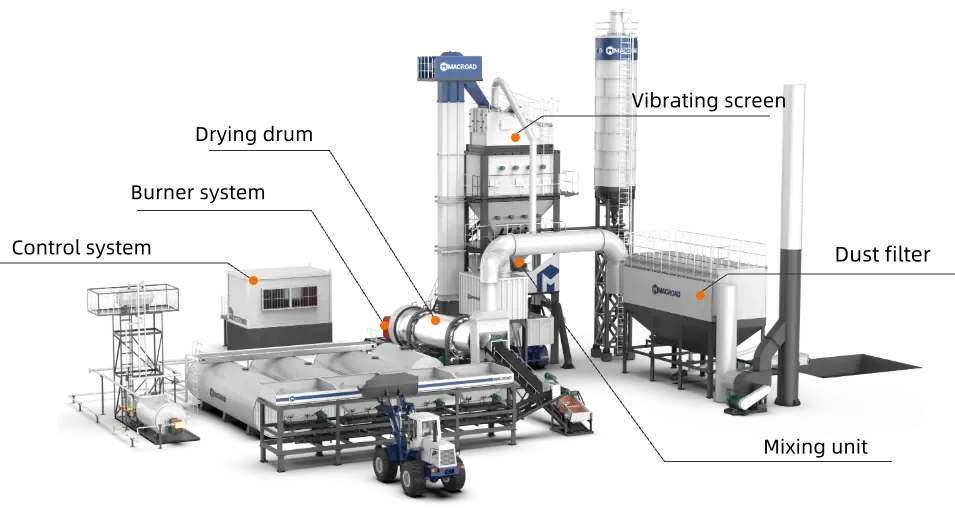

To ensure that each batch of asphalt possesses sufficient strength, viscosity, and uniformity, the asphalt hot mix plant is the most crucial element. Through precise heating and uniform mixing, it ensures that the aggregate and asphalt are fully bonded and integrated at ideal temperatures, guaranteeing the road’s smoothness, durability, and construction efficiency from the outset.

Why modern roads need asphalt hot mix plant?

For any road project striving for high standards, the quality of the asphalt mixture is never a matter of chance, but rather the result of precise control and scientific processes.

Hot mix plant is the core of this process—through high-temperature drying, intelligent metering, and uniform mixing, asphalt and aggregates achieve optimal fusion at ideal temperatures and times. This not only affects the current paving efficiency but also determines the road’s durability and safety for years to come. The following four aspects are the key reasons why hot mixing plant cannot be replaced.

Extending Road Lifespan, Preventing Aging from the Source

Hot asphalt mixing plant can precisely control aggregate heating and asphalt coating thickness, achieving ideal density and gradation in the mixture. The dense structure formed by high-temperature mixing effectively blocks the intrusion of moisture and oxygen, significantly reducing the risk of aging and spalling. Compared with cold mix asphalt plant, road service life can be extended by 3-5 years or even longer, resulting in a significant reduction in long-term maintenance costs.

Smoothness Determines Comfort

For high-standard projects such as airport roads or highways, road smoothness is a key indicator—longitudinal error ≤3mm/3m. The hot mix plant for road construction ensures that aggregate and asphalt are fully integrated, resulting in stable mixture viscosity and a denser, smoother surface after paving. Even at high speeds, vehicles can maintain stable driving, greatly improving safety and comfort.

Resisting High Temperatures, Stable and Rutting-Resistant

In high-temperature regions such as Southeast Asia, the Middle East, and Africa, roads often develop ruts due to softening. Hot asphalt plant can flexibly blend high-viscosity or polymer-modified asphalt, allowing the mixture to maintain a high-strength structure even above 60℃. Whether facing heavy truck traffic or extreme weather conditions, it maintains a stable road surface.

Adapting to diverse working conditions and projects

Another major advantage of hot mix asphalt equipment is their customizability. Whether for port construction, tunnels, mountain roads, or road construction in cold regions, specialized mixtures can be produced to meet different temperature, load, and environmental requirements by adjusting aggregate gradation, adding fibers, recycled materials, or special additives. From airports to rural roads, it provides a one-stop solution for various engineering requirements.

From Highways to Country Roads: Asphalt Hot Mix Plant at Work

The significance of hot mix plant extends beyond simply producing high-quality asphalt mixtures. Different construction environments—whether urban arterial roads, inter-provincial highways, or temporary roads in remote mountainous areas—each scenario has its own unique construction rhythm and technical requirements.

Therefore, choosing the right type and configuration among types of hot mix asphalt means higher capacity utilization, shorter construction periods, and more consistent pavement quality. Below, we’ll examine how hmp plant truly realize their value through different engineering scenarios.

| Urban expressways and flyovers: | large traffic volume and high speed, with strict requirements on flatness, compaction and water damage resistance. It is necessary to match fixed large-scale asphalt hot mix plant and multi-storage material systems to ensure continuous and efficient feeding. |

| National highways and primary trunk lines: | long-term large-scale and stable feeding is required. 150-300t/h large-scale fixed mixing plants are preferred to support nighttime construction and ultra-long operation cycles to avoid material interruption affecting paving quality. |

| Airport runways and port logistics parks: | high wheel load pressure requires the addition of modified asphalt and fiber reinforcement. The mixing station needs to have precise asphalt temperature control and dual metering systems to prevent heat loss or premature aging of asphalt. |

| Mining areas, oil fields and remote mountain roads: | Highways have high demands on the quality of asphalt on the road surface due to their high volume of traffic. Batch asphalt mixing plants can meet the asphalt quality requirements of highway kilometers. |

| Rural roads and renovation and maintenance: | For medium-sized projects or intermittent construction, drum type hot mix plant is the preferred choice due to their low cost and easy operation, and can achieve stable material supply within a limited budget. |

Application Scenarios and Benchmark Cases of Asphalt Hot Mix Plant

High-Quality Asphalt in Mongolia’s Harsh Winter with ALQ80

- Project Time: 2025.10

- Project Technical Supervisor: Even in 0℃ conditions, the ALQ80 consistently produces high-quality asphalt, significantly reducing the risk of cracks.

ALQ120 Asphalt Hot Mix Plant Ensures On-Time Delivery for Malaysia Project

- Project Location: Malaysia Sabah

- Construction Project Manager: The equipment operated steadily, meeting daily production targets and allowing us to deliver the project on schedule.

On-Site Training with ALQ80 Enables Kyrgyz Team to Master Operations Quickly

- Capacity: 80tph

- Training Engineer: After on-site training, the client team can operate the equipment independently with precise control and proper maintenance.

ALT80 Asphalt Hot Mix Plant Makes Hot Mix Production Easy for New Clients in Malaysia

- Project delivery time: 2025.10

- Client Operations Supervisor: Even operators new to asphalt plants quickly became familiar with the process and maintained stable output.

ALYT80 Flexibility Supports Multi-Site Operations in Bosnia

- Capacity: 80TPH

- On-Site Construction Supervisor: The equipment is quick to assemble and relocate, effortlessly handling mountainous and multi-site operations.

Two Core Asphalt Hot Mix Plants to Precisely Match Project Requirements

Different application scenarios have different requirements for asphalt hot mix plant. A full understanding of the equipment can help you quickly choose the right amp hotmix. At Macroad, according to the construction characteristics of different scenarios, hot mix asphalt mixing plants are mainly divided into two types, now let’s see what is hot mix plant in Macroad.

ALQ series

- Models: ALQ40 ALQ60 ALQ80 ALQ100 ALQ120 ALQ160 ALQ320

- Production Capacity: 40-400 t/h

- Mixing Cycle: 45s

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

ALYQ series

- Model: ALYQ40 ALYQ60 ALYQ80 ALYQ100 ALYQ120

- Production capacity: 40-160 t/h

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

- Asphalt temperature: 120-180 ℃

- Mixing Cycle: 45s

Highlights of Asphalt Batch Mix Plant

Quality Assurance and Safe Operation

- Optimized Asphalt Performance: Optimized blade structure within the drying drum achieves efficient heat exchange, increasing thermal efficiency by 25%. This ensures uniform heating of the asphalt and thorough coating of the aggregate, asphalt batching plant guaranteeing the bond strength of the mixture from the source.

- Safe and Reliable Operation: A double-row chain lifting system provides full-process protection for hot aggregate conveying, eliminating the risk of spillage or jamming during operation and ensuring hot mix plant working safety.

High Output, Low Consumption, and Cost Advantages

- Strong Capacity: A large-capacity mixing tank combined with a co-current drying drum increases the efficiency of cold aggregate moisture removal by 30%, ensuring stable hotmix plant hourly output and meeting the needs of large-scale continuous supply.

- Intelligent Cost Control: The PLC electrical control system automatically optimizes the batching process, reducing manual intervention and saving 30% of labor costs. It also supports free switching between coal and oil fuels, adapting to different regional energy supplies and reducing fuel costs.

Intelligent Maintenance and Worry-Free Operation

- Self-Diagnosis: Integrated automatic fault diagnosis device monitors equipment operating status in real time, providing early warnings and locating problems. It supports unattended operation, improving maintenance efficiency by 50%.

- Energy-saving design: The drying drum with concurrent heating combined with the central air guide structure reduces heat loss, increases heating speed by 20% compared to traditional hot mix plant for sale, and consumes less energy.

ALT series

- Model: ALT20 ALT40 ALT60 ALT80 ALT100

- Production capacity: 20-100 t/h

- Dust filter: Bag/Water dust filter

- Asphalt temperature:120-180 ℃

- Finished Asphalt Storage Bin: 3-9 tons

ALYT series

- Model: ALYT20 ALYT40 ALYT60 ALYT80 ALYT100 ALYT120

- Production capacity: 20-120 t/h

- Dust filter: Bag/Water dust filter

- Asphalt temperature: 120-180 ℃

- Cold Aggregate Feeding Capacity: 3.5m³ – 6.5m³

Highlights of Asphalt Drum Mix Plant

Continuous Mixing, Stable and Efficient Material Supply

- Continuous Production Throughout the Entire Process: The drum asphalt mixing plant adopts an integrated structure for continuous drying and mixing, ensuring smooth material flow and enabling 24-hour uninterrupted operation, significantly shortening the construction cycle.

- High-Efficiency Thermal Energy Utilization: The double drum hot mix plant guide and co-current heating structure improves thermal energy utilization by 30%, resulting in more uniform heating and lower heat loss.

- More Stable Material Supply: The continuous feeding and discharging system avoids batch interruptions, ensuring paving continuity and consistent mixture temperature.

Compact Structure, Efficient and Stable Layout

- Integrated Modular Design: The drum body, burner, dust removal, and electrical control system are highly integrated, resulting in a simple overall structure, reducing external connection points, lowering working of hot mix plant risks, and reducing energy consumption.

- Smaller Footprint, Faster Installation: Optimized hot mix type mobile asphalt plants layout reduces the overall footprint by approximately 25% compared to traditional equipment, shortening the installation cycle and making construction preparation more lightweight.

- High Reliability Design: The drum support system and transmission device are dynamically balanced to ensure low vibration and low noise during long-term continuous operation.

Environmentally Friendly and Energy-Saving, Intelligent Control

- Resource Recycling: An innovative dust recovery system achieves 99% recycling, saving 15%–20% of raw material costs in hot mix plant working process annually per unit.

- Intelligent Control System: PLC automatically controls temperature, feed rate, and asphalt spraying ratio, dynamically compensating for weighing errors. Aggregate content ≤0.3%, powder and asphalt content ≤0.25%, ensuring stable output quality.

- Energy-Saving and Low-Consumption Design: Drying and mixing are combined in the same drum, resulting in a shorter heat transfer path and reducing energy consumption by 15%–25% compared to traditional hot mix plant process.

Hot Mix Plant Specification

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

From Raw Materials to Finished Mix: The Journey of Hot Mix Asphalt

The hot mix asphalt plant operations determines the stability and durability of the asphalt mixture. The entire asphalt plant process is coordinated and controlled by an intelligent system, ensuring that each batch of mixture reaches its optimal state through multi-level temperature management, precise weighing, and efficient mixing. Its main process can be divided into six stages. The following may answer the question how to make hot mix asphalt.

Cold Aggregate Feeding and Proportioning

Aggregates of different sizes are fed into cold aggregate bins by loaders and then conveyed to the drying system via speed-regulating belts. In this stage, the raw materials are initially proportioned according to a preset hot mix plant rate and ratio to ensure a stable and accurate supply of aggregates of each specification.

Drying and Heating

The proportioned cold aggregates enter the drying drum, where they are continuously tumbled under the action of high-temperature airflow from the burner, achieving uniform dehydration and heating to bring the aggregate temperature to the required level for mixing. This process is one of the key steps determining the quality of the mixture, ensuring that the aggregates can fully combine with the asphalt during solid hot mix plant subsequent mixing.

Screening and Hot Aggregate Storage

The heated aggregates are conveyed to a vibrating screen via a hot aggregate elevator, where they are graded and screened according to particle size and stored separately in individual hot aggregate bins. The screened aggregates are kept dry and at a high temperature to prepare for accurate weighing and mixing.

Weighing and Feeding

According to the formula requirements, the system accurately weighs the aggregates, mineral powder, and asphalt sequentially. Each component is added to the mixing unit in the specified proportions to ensure stable composition and accurate proportions in each batch of the mixture.

Mixing

Inside the mixing unit, aggregates and asphalt are thoroughly mixed at high temperatures. A twin-shaft or drum mixing structure ensures that the asphalt evenly coats the aggregate surface, forming a dense and stable hot-mix asphalt mixture.

Finished Product Discharge and Storage

The mixed hot-mix asphalt is discharged into the finished product silo through the discharge port or directly loaded into transport vehicles. At this stage, temperature control and discharge rhythm are optimized to ensure that the mixture maintains a suitable temperature and good workability during transportation and paving.

Asphalt Hot Mix Plant: Invest Once, Benefit Long-Term

After understanding the structure and operation of hot mix plant, the most practical question is the price of hot mix plant. Different production capacities, configurations, and mobility directly affect the asphalt mix plant price; however, more crucially, the energy consumption, maintenance, and management costs during operation often determine the project’s true rate of return.

Therefore, when evaluating cost of hot mix plant, in addition to the purchase price, it’s more important to focus on how to continuously reduce the total cost of ownership (TCO) over its lifespan, ensuring a higher return on every investment.

Hot Mix Plant Price List Range Overview

The price of hot mix asphalt plant for sale varies significantly depending on capacity, type, and level of automation:

- ALQ40-ALQ320 batch type hot mix plant price: $220,000-$1,220,000

- ALYQ60-ALYQ120 mobile hot mix plant price: $270,000-$440,000

- ALT20-ALT80 drum type hot mix plant price: $60,000-$210,000

- ALYT20-ALYT120 portable hot mix plant price: $60,000-$200,000

Key factors influencing price include: capacity, fuel type, dust control standards, level of automation. For example mobile mini hot mix plant and portable hot mix asphalt plant wouldn’t share the same price. However, regardless of the configuration, the true determinant of profitability is the equipment’s overall performance in terms of energy consumption, maintenance, efficiency, and stability.

How to Effectively Reduce the Total Cost of Ownership of Hot Mix Plant

Purchasing a hot mixing plant is just the beginning. The real impact on project profitability lies in the operating and maintenance costs throughout the equipment’s lifespan. The following aspects can help you systematically reduce expenses and make your equipment more efficient and durable.

High-Efficiency Combustion and Heat Recovery-Maximizing the Value of Every Drop of Fuel

- Saving Logic: The energy consumption of an asphalt hot mix plant mainly comes from the aggregate drying and heating process. Higher combustion system efficiency results in lower heat loss and naturally lower fuel costs.

- Optimization Method: Employing precision-controlled burners and optimized airflow design ensures full contact between the flame and aggregate; waste heat recovery is added to the exhaust system to reduce heat waste.

- Results: Fuel consumption can be reduced by approximately 10%–30%, saving tens of thousands of US dollars in fuel costs annually for long-term projects.

- Extended Value: More complete combustion also means lower emissions, better meeting environmental protection requirements.

Intelligent Control System-Enhancing Production Stability and Reducing Labor Costs

- Saving Logic: Automated systems can precisely control feeding, weighing, and mixing times, reducing human error and avoiding rework and waste caused by inaccurate proportions.

- Optimization Method: Integrated PLC system, automatic formula management, dynamic replenishment weighing, and real-time monitoring replace tedious manual operations.

- Results: Operators are reduced by 20%–40%, production capacity is more stable, and material loss is lower.

- Extended Value: Long-term use accumulates production data, providing a basis for later formula optimization and maintenance prediction.

Wear-resistant Structure and Long-Life Design-Enabling Longer Equipment Lifespan and Fewer Repairs

- Saving Logic: The longer the lifespan of wear parts such as mixing blades, liners, and elevators, the lower the downtime maintenance and replacement costs.

- Optimization Method: Utilizing high-chromium wear-resistant alloys, modular blade design, and enhanced heat dissipation and lubrication systems.

- Results: Wear part lifespan can be extended by more than 50%, reducing downtime and significantly lowering maintenance costs.

- Extended Value: Longer continuous operating time translates to higher capacity and profits.

Modular Design-Saving Money from Transportation to Installation

- Saving Logic: Traditional asphalt mixing plants have long installation cycles and complex construction; modular structures allow for pre-assembly in the factory, requiring only on-site connection.

- Optimization Method: Standardized modular transportation, pre-laid cables and pipelines, and rapid assembly

- Results: Installation cycle reduced by 30%–50%, significantly reducing construction labor and site costs.

- Extended Value: Faster project launch and earlier capital recovery capability especially for for mini and portable hot mix asphalt plant.

Preventative Maintenance and Remote Diagnostics-Reduced Unplanned Downtime

- Saving Logic: Early detection of potential problems is more cost-effective than reactive repairs.

- Optimization Methods: Install sensors on key components to monitor temperature, vibration, current, and other conditions; remote systems provide real-time alarms and diagnostics.

- Results: Reduced sudden downtime by approximately 20%–30%, lower maintenance costs, and more continuous production.

- Extended Value: Systematic maintenance extends equipment lifespan and avoids production losses from unexpected major overhauls.

Procurement and Spare Parts Management-Advance Planning, Reduced Long-Term Expenses

- Saving Logic: Spare parts procurement is often scattered and temporary, resulting in higher prices and potential downtime due to shortages.

- Optimization Methods: Sign long-term supply agreements, establish local warehousing, and plan replacement cycles for vulnerable parts.

- Results: Spare parts costs decrease by 5%–20%, significantly reducing downtime risk.

- Extended Value: Make maintenance more controllable, ensuring the hot mix asphalt plant near me is always in optimal operating condition.

Lowering the total cost of hot mix plant is not just about saving money; it’s about making every production run more efficient and reliable. These optimizations work together to save businesses hundreds of thousands of dollars over the equipment’s lifecycle, while simultaneously improving engineering quality and brand competitiveness.

Faster Production? EPC Solutions Cut Construction Time by 30%

Previously, we analyzed in detail the workflow, investment costs, and long-term benefits of hot-mix asphalt mixing plants. However, for large-scale road, airport, or port projects, simply purchasing equipment is far from sufficient—from park planning and civil construction to equipment installation and commissioning, every step affects the project’s commissioning speed and cost.

In this case, choosing an EPC (Engineering, Procurement, and Construction) turnkey solution provided by asphalt mixing plant manufacturers can integrate complex processes into a controllable and predictable workflow, enabling the project to be implemented quickly and efficiently. Macroad as one of the hot mix plant manufacturers, provides full professional support throughout the entire EPC process, ensuring that equipment and engineering are optimized simultaneously, helping clients achieve stable production in the shortest possible time.

Park Planning and Process Design

- Macroad is responsible for: Optimizing the layout of aggregate bins, mixing units, asphalt storage tanks, and transportation routes based on the operating characteristics of hot mix plant to ensure smooth production processes.

- What you get: A clear and reasonable overall park plan, smooth equipment and logistics connections, and more convenient construction.

- Advantages: Improved construction and equipment installation efficiency, reduced conflicts and delays, and faster commissioning.

Civil Engineering and Supporting Construction

- Macroad is responsible for: Constructing a complete set of infrastructure, including plant buildings, roads, drainage systems, control rooms, finished product silos, and dormitories.

- What you get: A complete production park supporting 24/7 hot mixing plant production, eliminating the need to coordinate with multiple contractors.

- Advantages: Reduced construction risks, lower management costs, and more controllable project progress.

Equipment Supply and Installation

- Macroad is responsible for: Modular prefabricated asphalt hot mix plant equipment and providing on-site assembly and installation guidance.

- What you get: Rapid equipment deployment and significantly shortened installation time.

- Advantages: Early production commencement, shortened overall construction period, and reduced labor and commissioning costs.

System Debugging and Integration

- Macroad is responsible for: synchronous debugging of electrical, control, and weighing systems, and completing trial production.

- What you get: Seamless integration of hot asphalt mixing plant and process, enabling direct production of high-quality asphalt mixtures.

- Advantages: Reduced trial operation risks, ensuring stable and reliable initial output.

Operation Training and Operational Support

- Macroad is responsible for: Hot mix plant supplier providing operator training, daily maintenance guidance, and remote technical support.

- What you get: The team quickly masters operating skills, ensuring smooth and unimpeded production.

- Advantages: Reduced operational errors and downtime risks, long-term improvement in capacity and return on investment.

Long-Term Maintenance and Optimization

- Macroad is responsible for: Monitoring hot asphalt plant operating status and providing suggestions for energy saving, formula optimization, and maintenance improvements.

- What you get: Continuous access to equipment operating data and improvement plans.

- Advantages: Increased equipment utilization, extended service life, and reduced long-term maintenance costs.

With Macroad’s integrated EPC solution, you not only get a high-performance asphalt hot mix plant, but also enjoy one-stop optimized services from park planning to commissioning and operation. Every step is designed specifically for the characteristics of hot-mix asphalt mixing plants, shortening the construction cycle, reducing risks, maximizing return on investment, and enabling your project to achieve efficient production as quickly as possible.

Whether you’re building highways, airport roads, urban arterial roads, or rural roads, the quality and lifespan of every road begins with the asphalt hot mix plant. Choosing the right equipment means laying a solid foundation for your project; choosing Macroad means not only choosing a high-performance hot mix plant, but also receiving a complete set of professional support from planning and construction to commissioning, making your investment more stable and your output more efficient.

Let Macroad help you build an efficient, reliable, and sustainable road construction production system, maximizing the value of every investment. Contact us to make your road construction projects easier and more efficient!