localized service network

customized equipment solutions

In Indonesia, road construction projects are widespread, ranging from busy highways on Java to municipal roads and industrial park access roads on Sumatra, Kalimantan, and other islands. Each construction site presents unique challenges: humid coastal environments, mountainous terrain, traffic congestion, and even inter-island construction all place stringent demands on asphalt production. Faced with these diverse challenges, efficient, stable, and locally adapted asphalt mixing plants are crucial for project success.

Choosing asphalt mixing plant indonesia suitable for various Indonesian regions, construction schedules, and production requirements, and combining this with localized services to ensure rapid deployment, stable operation, and long-term profitability, is a critical consideration at every project planning stage.

Application of Asphalt Mixing Plants in Indonesian Road Projects

In Indonesia, different types of road projects exhibit significant variations in their reliance on and use of asphalt production. From national highways and urban roads to regional connecting roads and supporting infrastructure, asphalt mixing plants have become a critical component in ensuring construction continuity and cost control. Based on project type and construction environment, asphalt mixing plants are primarily used in the following typical scenarios in Indonesia:

| Highways and National Main Roads: | Primarily concentrated on Java and Sumatra islands, these projects have long duration and high construction intensity, requiring extremely high continuity of asphalt supply. In projects such as the Trans-Java and Trans-Sumatra Toll Roads, configuring stable aspal mixing plant indonesia helps ensure continuous material supply during peak construction phases and reduces the risk of delays due to supply fluctuations. |

| Municipal Roads and Urban Renewal Projects: | Mostly located in cities such as Jakarta, Surabaya, and Bandung, these projects have a fast pace and multiple batches, requiring high stability in asphalt quality and production flexibility. Urban road projects typically utilize nearby asphalt mixing plants to meet the needs of frequent, small-batch production, while also better addressing the quality inspection and acceptance requirements of municipal engineering projects. |

| Provincial Roads and Regional Connecting Roads: | Common in Kalimantan and Sulawesi regions, these projects are dispersed, and logistics conditions are limited, resulting in high transportation costs and unstable supply of purchased asphalt. By setting up asphalt mixing plant indonesia within the construction area, transportation dependence can be significantly reduced, and construction autonomy can be improved, making it suitable for medium-to-long-term regional road construction projects. |

| Ports, Industrial Parks, and Heavy-Duty Supporting Roads: | Roads serving port logistics and industrial parks require higher load-bearing performance and consistency of asphalt mixtures. In such projects, asphalt mixing plants not only undertake production tasks but also directly impact the durability and future maintenance costs of the roads. |

| Island and Phased Construction Projects: | Often found in the eastern Indonesian islands, these projects have relatively defined timelines, but the construction sites are scattered. These projects focus more on equipment deployment efficiency and operational stability. By rationally configuring asphalt mixing plants, road construction can be completed within the limited timeframe, reducing overall construction complexity. |

On the Ground: Indonesian Road Construction Projects

ALQ80 Asphalt Mixing Plant Supports Trans-Sumatra Freeway in Palembang

- Capacity: 80tph

- Project Overview: Palembang’s heat and heavy rain put constant pressure on production. The ALQ80 ran steadily day and night, with consistent mix quality. We didn’t have to stop and adjust often, which helped us keep the freeway schedule on track.

ALQ80 Asphalt Batch Plant Optimized for Urban Road Projects in Jakarta

- Capacity: 80tph

- Site Engineer’s Review: Space was our biggest issue in Jakarta. The ALQ80 fit the site without complicated rearrangements. Start-ups were smooth, quality stayed stable despite frequent stops, and installation support was fast and well organized.

ALQ80 Asphalt Plant Performs Reliably on Coastal Highway in Bandar Lampung

- Capacity: 80tph

- Project Manager’s Feedback: Humidity and sea air usually cause problems, but this plant stayed reliable throughout the project. Drying efficiency was stable, and spare parts support was quick. We avoided unplanned downtime, which was critical for our coastal schedule.

ALQ100 Asphalt Mixing Plant Handles Mountain Road Construction in Subang

- Capacity: 100tph

- Site Engineer’s Review: Subang’s terrain and weather change quickly. The ALQ100 was easy to install even on uneven ground and kept output consistent. It handled long operating hours well, and technical support was always available when needed.

Recommended Asphalt Plant Models for Indonesian Conditions

In Indonesia, road projects are undertaken in significantly diverse environments, ranging from hot and humid coastal areas to inland regions with complex terrain and limited logistics, and densely populated urban construction sites. The demands on asphalt mixing plant indonesia vary considerably depending on the specific project.

Based on extensive project experience in the Indonesian market, Macroad has not adopted a single solution for its equipment design and configuration. Instead, it has developed a multi-series asphalt plants portfolio tailored to construction environments, project cycles, production capacity requirements, and operating methods, to better suit the actual usage scenarios of different regions and project types in Indonesia.

The following four types of equipment are widely used in various road construction projects to meet the common application needs of the Indonesian market.

ALQ Series — Ensuring Quality and Stability for Large-Scale Road Construction Projects

The ALQ series asphalt batching plant primarily designed for long-term, large-scale road construction projects in Indonesia, such as national highways and main road projects. This series excels in precise proportioning and stable operation, making it suitable for continuous production under high-load conditions, and is particularly well-suited for projects requiring high consistency in asphalt mixture quality. In areas with high construction intensity, such as Java and Sumatra, the ALQ series is frequently used to ensure continuous material supply and quality control during long-term construction projects.

- Model: ALQ40-ALQ320

- Production capacity: 40-320 tons/hour

- Mixing cycle time:45s

- Asphalt temperature: 140-180 ℃

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

ALYQ Series — Flexible Choice for Dispersed Projects and Phased Construction

While maintaining the precision of intermittent mixing, the ALYQ series mobile asphalt batching plant emphasizes equipment mobility and deployment efficiency, making it suitable for Indonesian road engineering projects with widely distributed sites or those requiring phased relocation. In provincial road construction, regional connecting roads, and some outer island projects, the ALYQ series can be installed and put into production in a short time, helping projects maintain stable asphalt quality under flexible construction conditions.

- Model: ALYQ40-ALYQ120

- Production capacity: 40-120 tons/hour

- Mixing cycle time:45s

- Asphalt temperature: 120-180 ℃

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

ALT Series — High-Efficiency Production Solutions for Continuous Construction Projects

The ALT series stationary asphalt mixing plant, centered on continuous production and simplified structure, is ideal for Indonesian road projects with stable production demands and continuous construction schedules. In Jakarta, Surabaya, and Kalimantan, the ALT series is widely used in industrial park roads, municipal functional roads, and provincial road maintenance projects to ensure a continuous supply of asphalt, guaranteeing uninterrupted construction while reducing transportation and operating costs. It is particularly suitable for small and medium-sized Indonesian road projects with limited resources and tight project timelines.

- Model: ALT20-ALT100

- Production capacity: 20-100 tons/hour

- Fuel consumption:13-15kg/t

- Asphalt temperature: 120-180 ℃

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

ALYT Series — Rapid Deployment Solution for Remote and Island Projects

The ALYT series mobile asphalt drum mix plant combines the advantages of continuous drum-mix production and mobile structure, primarily serving projects with defined construction timelines and high demands for efficient relocation. In Indonesian island regions or areas with limited logistics, the ALYT series can be quickly deployed and relocated, providing a more flexible asphalt production method for projects and reducing reliance on external supplies.

- Model: ALYT20-ALYT120

- Production capacity: 20-120 tons/hour

- Dust filter: Bag/water dust filter

- Asphalt temperature: 120-180 ℃

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

Technical Innovations Tailored to Indonesian Road Projects

Road construction projects in Indonesia exhibit significant regional variations, with unique requirements in terms of raw materials, construction specifications, and climate conditions. High temperatures, humidity, rainfall, logistical constraints, and differences in project supervision present numerous challenges for asphalt mixing plant indonesia in terms of production stability, quality control, and ease of maintenance.

To address these challenges, Macroad has made targeted improvements to its equipment design, upgrading and optimizing six core systems to ensure that each asphalt mixing plant indonesia operates efficiently and reliably in different regions of Indonesia.

Drying System

- Challenge: In coastal areas and during the rainy season, high humidity leads to significant fluctuations in aggregate moisture content, resulting in uneven drying and unstable mix quality.

- Technical Improvement: Optimized hot air circulation and duct design, along with the use of moisture-resistant and corrosion-resistant materials, ensure even heat transfer and rapid, thorough drying of aggregates.

- Effect: By stabilizing the drying process, consistent aggregate moisture content is ensured, resulting in stable mix quality, reduced rework and construction delays, and lower fuel consumption, leading to higher production efficiency.

Aggregate Lifting System

- Challenge: The varied terrain of Indonesia’s mountains, plains, and outer islands, coupled with narrow construction areas and complex soil conditions, makes aggregate transportation prone to blockages or interruptions due to terrain and wet materials.

- Technical Improvement: Upgraded conveyor trough shape and impeller structure, added anti-clogging design and wear-resistant treatment of key components to ensure smooth material transport.

- Effect: Improved conveying continuity, ensuring stable operation even under sloping or wet material conditions, reducing downtime frequency, guaranteeing smooth construction progress, and improving overall project construction efficiency.

Weighing System

- Challenge: In coastal areas of Indonesia and during the rainy season, fluctuations in raw material moisture content can easily lead to deviations in the proportion of aggregates, powders, and asphalt, affecting mix consistency.

- Technical Improvement: Upgraded aggregate, powder, and asphalt weighing modules, moisture-proof treatment of sensors, and the introduction of automatic compensation algorithms to correct proportion deviations in real time.

- Effect: Improved proportioning accuracy achieves a weighing accuracy error of ±0.5%, ensuring consistent mix quality, reducing rework rates and material waste, ensuring road construction meets design standards, and improving the reliability of construction results.

Mixing System

- Challenge: In some areas of Indonesia, high aggregate hardness and high mineral powder content can easily lead to uneven mixing or equipment wear, increasing maintenance costs.

- Technical Improvement: Optimized mixing blade angle and mixing chamber structure, using high wear-resistant materials, resulting in more uniform and durable mixing.

- Effect: Improved mixing uniformity and equipment lifespan, reducing manual adjustments and maintenance downtime, ensuring stable construction quality, and lowering long-term operating costs.

Dust Removal System

- Challenge: High dust environment in coastal and industrial areas, resulting in significant material loss and increased pressure on site safety and environmental management.

- Technical Improvement: Adopting a cyclone + bag filter dual-stage dust removal system, and adding a real-time dust monitoring and alarm system to achieve efficient dust capture.

- Effect: Improved material recovery rate, air dust concentration meets environmental requirements, reduced site pollution, and reduced material loss, ensuring construction safety and environmental compliance.

Finished Material Silo and Discharge System

- Challenge: During multi-project or peak construction phases, there is significant pressure on continuous asphalt supply, and frequent replenishment affects construction efficiency.

- Technical Improvement: Adding a large-capacity silo, combined with intelligent output control and adjustable discharge port design, to ensure smooth and controllable discharge.

- Effect: Reduced frequent replenishment, improved continuous construction efficiency, ensured stable asphalt supply at the construction site, and reduced manual operation difficulty and operating costs, making projects more flexible and efficient.

Indonesia’s road construction environment is highly variable, ranging from humid coastal areas to mountainous terrain and remote island projects with limited access. Each region presents different challenges for asphalt production. Through targeted design and improvements to its six core systems, Macroad has addressed issues such as fluctuating moisture content in materials, supply interruptions, unstable mix ratios, and equipment wear, resulting in stable construction quality, high production continuity, and controllable operating costs.

Tailored Solutions for Every Indonesian Road Project

Road projects across Indonesia face significantly different environmental conditions: coastal areas are highly humid, mountainous regions are undulating, and construction on outer islands is often restricted. Each project therefore has unique requirements regarding the capacity, deployment speed, and ease of maintenance of aspal mixing plant indonesia. To help construction teams quickly find equipment suitable for their projects, we have compiled common scenarios into specific questions and answers, providing practical recommendations for each environment.

My project involves building a highway on Java Island, requiring 3000 tons of asphalt mix daily. Which type of plant should I choose?

I’m working on construction projects across multiple islands in Sulawesi, and moving equipment is a major hassle. Do you have any quick-assembly solutions?

When constructing municipal roads along the coast of Surabaya, the high humidity makes raw materials susceptible to moisture. Which equipment is the most reliable?

I’m working on a construction project in a remote area of Kalimantan, where raw material transportation is slow and spare parts are difficult to obtain quickly. What should I do?

For road construction in the Jakarta industrial park, the project requires stable output but has strict harga asphalt mixing plant di indonesia requirements. Which equipment should be chosen?

When constructing roads in tourist areas in Bali, the construction period is short but the work area is narrow. Are there any suitable equipment options for confined spaces?

Construction in the mountainous regions of Sumatra involves numerous slopes and frequent rainy seasons, which can easily disrupt aggregate transportation. How to choose the right equipment?

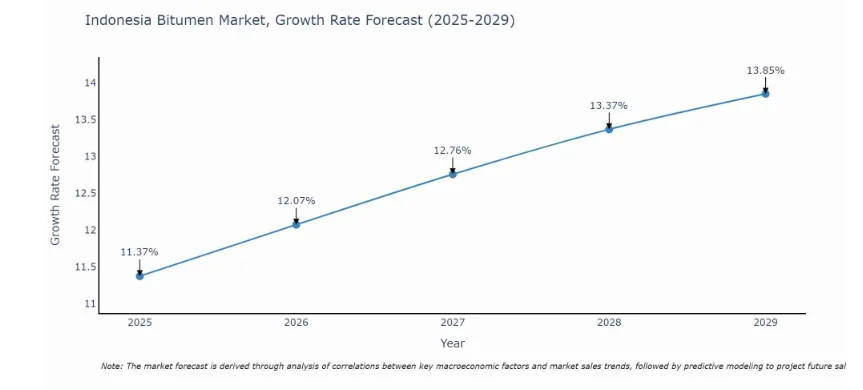

Why Now Is the Best Time to Invest in Asphalt Mixing Plants in Indonesia

Indonesia’s road construction projects span across all islands of the archipelago, from highways and national trunk roads to urban municipal roads and industrial park roads. The demand for asphalt mix is stable and growing rapidly each year. This is accompanied by increasingly concentrated raw material supply, accelerated construction schedules, and stricter environmental requirements, making efficient and reliable asphalt mixing plant indonesia a core competitive advantage in the market. To understand the value of investing in asphalt mixing plants in Indonesia, a thorough analysis of policies, market demand, and construction distribution is necessary.

Infrastructure Policy Drivers

- Increased Government Investment: The Indonesian government is implementing the National Infrastructure Acceleration Program, including highway expansion, urban road upgrades, and industrial park road construction, providing policy support and stable demand for long-term asphalt mixing plant investments.

- Key Project Guidance: The Trans-Sumatra highway, Java island urban renewal, and industrial park projects provide the market with clear construction plans and investment directions, helping equipment investors secure high-quality projects.

- Long Policy Dividend Cycle: Long-term planning ensures continued demand for road construction over the next 5-10 years, allowing mixing plant investments to secure stable orders and cash flow, reducing investment uncertainty.

Large and Diverse Road Construction Demand

- Highways and National Trunk Roads: These projects have high output and long construction cycles, creating a significant demand for large-capacity fixed plants, ensuring high utilization rates and continuous revenue.

- Municipal Roads and Urban Renewal Projects: Limited construction space and complex environments create a significant market demand for compact and mobile high-efficiency plants, suitable for flexible investment strategies.

- Industrial Parks and Port Access Roads: Stable demand for continuous construction makes investing in continuous production equipment cost-effective while ensuring construction efficiency and maximizing output.

Raw Material Supply Distribution and Cost Advantages

- Abundant Resources at Coastal Ports: Convenient raw material transportation allows for rapid equipment operation, reducing procurement and transportation costs and improving construction efficiency.

- Logistical Challenges in Remote Areas: High transportation costs and unstable supply in outer islands and mountainous regions make local investment in asphalt mixing plant indonesia a way to reduce long-distance transportation risks and improve construction response speed.

- Centralized Raw Materials and Flexible Procurement: By strategically deploying equipment, production can be coordinated based on raw material supply in different regions, optimizing costs and achieving high-efficiency operations.

Market Competition and Opportunities

- Intense Competition in Mature Urban Markets: Jakarta and industrial parks already have established suppliers, resulting in relatively limited market space; success requires efficiency and equipment optimization.

- Unmet Demand in Remote Islands and Mountainous Regions: High-efficiency, mobile, or rapidly deployable equipment still has significant market gaps in these areas, offering opportunities for untapped markets.

- Great Potential for Cross-Project Services: Owning multiple pieces of equipment allows for coverage of different project types and regions, achieving high utilization rates and improving overall return on investment.

Environmental Protection and Construction Efficiency Requirements are Increasing

- Strict dust emission standards: The Indonesian government and local construction companies are raising environmental protection requirements. High-efficiency dust removal systems facilitate compliant construction and reduce the risk of fines.

- High-quality mix requirements: High-precision weighing, drying, and mixing systems ensure construction quality, reduce rework and material waste, and enhance the reputation of construction companies.

- Construction efficiency and energy saving pressure: Energy-efficient drying and high-efficiency mixing equipment can shorten construction cycles while reducing fuel and raw material consumption, increasing overall profitability.

Comprehensive Investment Value

- High demand + growth potential: The continuous advancement of infrastructure construction leads to a sustained increase in the demand for asphalt mix, providing reliable market support for asphalt mixing plant investments.

- Long-term stable returns: Through localized operations and efficient equipment, investors can achieve continuous construction output and order guarantees, ensuring long-term cash flow.

- Multi-dimensional risk control: Policy support, market demand, raw material supply, environmental protection, and construction efficiency are all controllable factors, reducing investment uncertainty and increasing return on investment.

In summary, Indonesia’s road construction is in a rapid development phase, and the market demand for high-quality asphalt mixtures is continuously increasing, from national highways to urban municipal roads and industrial park roads. For investors, now is the best time to enter the Indonesian asphalt mixing plant market, establish localized equipment, and seize market share.

Purchased Asphalt vs. Self-Built Asphalt Plant

However, when considering whether to invest in an asphalt mixing plant indonesia, many construction companies face a crucial decision: should I purchase asphalt directly from external suppliers, or buy asphalt plant directly? Each approach has its advantages and disadvantages, involving factors such as cost, construction flexibility, raw material control, and long-term profitability. To help you better understand the differences between these two options, we have compiled the following multi-dimensional comparison table for your reference and decision-making.

| Buying Asphalt | Comparison Dimension | Building Your Own Asphalt Mixing Plant |

| Low initial capital outlay; no equipment purchase required, only pay for the asphalt mix. | Initial Investment | Higher initial investment; requires purchasing equipment, building infrastructure, and training operators. |

| Long-term procurement costs may be higher; prices fluctuate with suppliers, and transportation costs increase with project location. | Long-Term Cost | After initial investment is recovered, raw materials can be sourced directly; production costs are more controllable, and long-term unit cost is lower than buying. |

| Dependent on suppliers and transportation; delays possible during rainy season, in remote islands, or mountainous areas. | Construction Flexibility | Production can be adjusted according to construction progress; equipment can be flexibly deployed, improving efficiency for remote or multi-island projects. |

| Material types and quality depend on suppliers; mix adjustments have limited flexibility. | Raw Material Control | Raw material ratios (aggregates, mineral powder, asphalt) can be controlled according to project needs, ensuring consistent mix quality. |

| No equipment maintenance required, but supplier quality and delivery must be monitored. | Maintenance & Management | Requires equipment maintenance and operational management; proper maintenance ensures long-term reliability and continuous construction. |

| Dependent on external supply; difficult to expand across multiple projects or islands. | Market Opportunities | Equipment can serve multiple projects and regions, improving market responsiveness and project acquisition capability. |

| Transportation may be affected by rainy season or remote/complex terrain, leading to material moisture or delays. | Environmental Adaptability | Localized production can optimize equipment operation for coastal, mountainous, and island environments in Indonesia, ensuring continuous construction. |

From a short-term financial perspective, purchasing asphalt externally involves lower initial investment and is suitable for small or one-off projects. However, considering long-term costs, construction flexibility, raw material control, and the ability to cover multiple projects, building an in-house asphalt mixing plant offers more significant advantages. Especially in Indonesia’s complex geographical environment and under cross-island construction conditions, building an in-house asphalt mixing plant indonesia can not only reduce long-term procurement costs but also improve construction efficiency and mix quality, leading to more stable returns for the project.

Accelerate Your Indonesian Road Projects with Localized Support

In Indonesia, construction projects involve vast geographical areas, complex environments, and diverse project types, making equipment selection just the first step. Macroad as professional asphalt plant supplier, has established a comprehensive localized service system in Indonesia, covering the entire process from selection to after-sales maintenance, ensuring that equipment can be quickly put into use and operate stably in the long term.

Our Indonesian service team is located at PT. AIMIX GROUP INDONESIA, Ruko Cleon Park, Jl. Jkt Garden City Boulevard No.55A, Cakung Tim., Kec. Cakung, Kota Jakarta Timur, Daerah Khusus Ibukota Jakarta, and can provide timely response and localized support to construction projects across the country, ensuring the smooth implementation and efficient operation of every project.

Selection Support

- Local Environment Adaptation: Recommending suitable models based on Indonesia’s coastal high humidity, mountainous terrain, and construction environments on outer islands, ensuring efficient operation under various topographical and climatic conditions.

- Production Capacity and Project Matching: Planning equipment capacity and configuration based on construction pace, daily mix requirements, and raw material types to avoid resource waste or insufficient capacity.

- Logistics and Construction Optimization: Considering island transportation, road conditions, and construction cycles, providing selection and layout suggestions to ensure rapid equipment deployment.

Production and Quality Inspection

- Localized Production: Key components are assembled in Indonesia, shortening transportation cycles and meeting the construction scheduling needs of different islands and remote areas.

- Strict Quality Inspection: Before leaving the factory, equipment is tested under simulated coastal high humidity, salt air, and mountainous construction environments to ensure mix accuracy and equipment stability.

- Reliability Assurance: The quality inspection process ensures a low failure rate for long-term equipment operation, improving construction continuity and project efficiency, and making investment risks controllable.

Shipping and Installation

- Fast Local Delivery: Utilizing the Jakarta service center (PT. AIMIX GROUP INDONESIA) and coastal ports to optimize transportation solutions, ensuring timely delivery to outer islands and mountainous construction sites.

- On-site Installation Guidance: Engineers guide equipment installation, system connection, and initial debugging, reducing pre-construction preparation time and accelerating start-up efficiency.

- Modular Rapid Deployment: Modular design and quick-assembly components improve the efficiency of relocation and deployment for multi-island and multi-project construction.

Commissioning and Training

- Precise Commissioning: Adjusting equipment parameters based on project mix requirements and construction pace to ensure stable output and qualified mix quality.

- Operator Training: Training local operators to master operation, maintenance, and safety procedures, improving the independent management capabilities of the construction team.

- Knowledge Summary: Providing operation manuals and technical guidance to help the team adapt to the asphalt mixing plant operating environment and use the equipment efficiently in the long term.

After-Sales and Remote Support

- Fast Local Response: The local Indonesian team promptly handles on-site problems and operational anomalies, shortening fault response time.

- Remote Monitoring and Early Warning: The Internet of Things system tracks equipment operating status in real time, identifying potential problems in advance and reducing downtime risks.

- Construction Continuity Guarantee: Combining remote guidance and on-site support to ensure stable equipment operation in coastal high humidity, mountainous, or remote outer island construction environments.

Maintenance

- Local spare parts warehousing: Key spare parts are stored locally in Indonesia to ensure quick replacement for remote construction sites and outer islands.

- Regular maintenance guidance: We provide maintenance plans and operational advice to extend equipment lifespan and reduce failure rates.

- On-site professional support: Engineers provide on-site assistance for complex repairs, ensuring uninterrupted construction and improving equipment efficiency.

Macroad’s localization services cover the entire process of Indonesian road construction projects, from selection and production quality control to shipping, installation, commissioning, and training, as well as after-sales remote support and maintenance. Each stage is optimized to suit Indonesia’s geographical and construction characteristics.

With our local service center in Jakarta, customers working in diverse environments—from humid coastal areas and mountainous regions to remote islands—can benefit from fast response times, reliable support, and efficient operations, maximizing the value of their asphalt mixing plant indonesia investment and ensuring the smooth completion of their projects.

Building high-quality roads in Indonesia presents challenges at every stage, from equipment selection to construction management. Leveraging years of global experience and localized service advantages, Macroad provides Indonesian clients with efficient, reliable, and flexible asphalt mixing plant indonesia solutions. Whether in humid coastal areas, mountainous regions, or on multiple projects across the outer islands, we ensure rapid deployment and stable operation of our equipment, maximizing the value of every ton of asphalt mix. Contact the Macroad team today to ensure your Indonesian road projects get off to a smooth start, deliver quick returns, and capitalize on every investment opportunity.