In traditional road construction sites, scheduling often relies on telephones, walkie-talkie, and experience. Asphalt mixing plants wait for transport trucks, transport trucks wait for pavers, and pavers wait for hot asphalt to arrive—information gaps cause frequent downtime and waste.

Now, all of this is quietly changing with a data line. With the emergence of intelligent scheduling systems, asphalt mixing plants, transport vehicles, and paving sites are tightly connected through digital networks: production progress, vehicle locations, and construction rhythm are synchronized in real time. Instructions no longer rely on human-to-human communication but are automatically calculated and precisely issued by the system.

From manual coordination to data-driven approaches, asphalt production are entering a new phase of minute-level response and end-to-end collaboration—this is the power of intelligent scheduling.

Limitations of Manual Scheduling in Construction Coordination

In most current road construction projects, asphalt mixing plants still rely primarily on manual scheduling. While this model offered flexibility in early projects, its limitations have become increasingly apparent as project scale expands and construction pace accelerates. The root of the problem lies in opaque information, delayed decision-making, and a lack of real-time feedback, making it difficult to establish stable collaborative relationships between different construction stages.

Delayed Information Transmission and Insufficient Response Speed

Scheduling relies on manual communication and individual experience, with production, transportation, and paving often managed separately by different personnel. Information is primarily transmitted via telephone or instant messaging, lacking a systematic platform support. When site conditions change, such as road congestion or equipment downtime, schedulers struggle to adjust production and transportation plans promptly, easily leading to imbalances such as overproduction at the asphalt mixing plant or material shortages at the construction site.

Lack of Data Support, Production Plans Disconnected from Actual Demand

Traditional scheduling is largely based on experience-based judgment rather than real-time data calculations. The lack of quantitative matching between asphalt plans and paving progress often results in waiting or empty runs for transport vehicles, reducing overall construction efficiency. Without dynamic data monitoring, managers struggle to accurately predict subsequent workloads and cannot identify potential delay risks in advance.

Low resource utilization and difficulty in cost control

Asphalt mixtures are highly sensitive to time and temperature. Transportation delays lead to material cooling and the need for secondary heating, increasing fuel consumption. Frequent start-up and shutdown operations not only exacerbate equipment wear and tear but also increase energy consumption and maintenance costs. Simultaneously, the significant manpower required for coordination and monitoring increases management costs and the risk of human error.

Lack of a unified monitoring and feedback mechanism leads to unstable construction rhythm

Management often cannot grasp the operational status of each stage in real time and can only rely on manual reports to understand progress. This information lag prolongs the problem response cycle, easily leading to unplanned interruptions such as waiting and work stoppages on site. Due to the lack of systematic data recording, quality traceability and performance evaluation are difficult to conduct in the later stages of the project, limiting the scope for management improvement.

The common thread in these problems is data fragmentation and scheduling lag. To achieve true construction collaboration, the key is to keep information flow and material flow synchronized in real time. This is precisely the reason for the emergence of intelligent scheduling systems.

How Intelligent Scheduling Systems Drive Construction Decisions with Data

As project scale expands and construction pace accelerates, traditional manual scheduling can no longer meet the dual demands for efficiency and accuracy. To truly achieve minute-level response in construction collaboration, the key lies in establishing a system capable of real-time perception, automated decision-making, and collaborative execution.

The intelligent scheduling system was developed in this context. It is not a single software or device, but a comprehensive platform operating through the collaboration of multiple technologies. Through the coordination of three core modules—GIS+IoT real-time monitoring, AI scheduling algorithms, and cloud-based collaborative management—the system enables data flow and logistics to be synchronized, making every decision faster, more accurate, and more controllable.

GIS+IoT Real-Time Monitoring: Making Site Status Visible

- Core Function: Through IoT terminals and Geographic Information System (GIS), the system collects and presents the real-time operational status of asphalt mixing plants, transport vehicles, and construction sites.

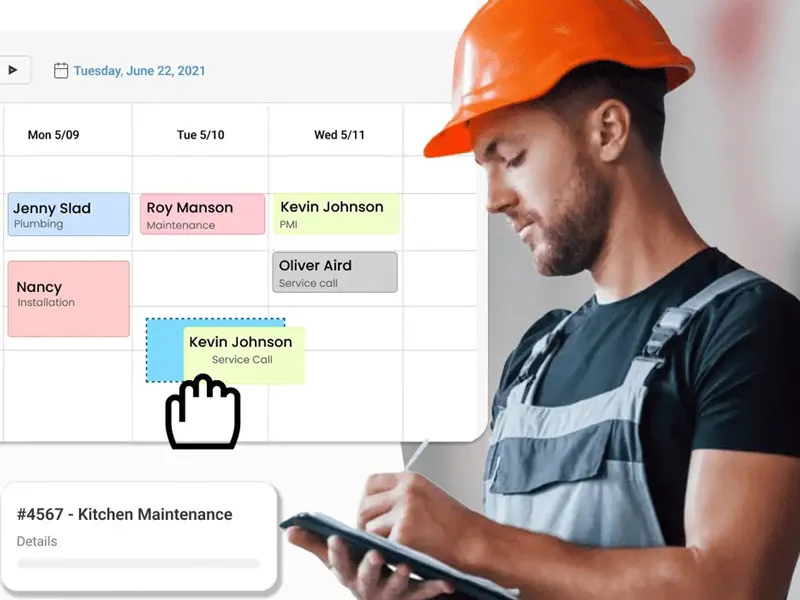

- Operation Mode: Each mixer, transport vehicle, and paving point is equipped with sensors and positioning modules. The system automatically uploads information such as location, material temperature, and operational status. Project managers can view in real-time on the control platform: which vehicles are transporting materials, which batches of materials have arrived on site, and whether the asphalt mixing plant’s output matches the construction schedule.

- Changes Brought About: The process that previously relied on telephone confirmation is replaced by real-time data. Production, transportation, and construction are all visualized and digitized. Dispatchers can immediately identify anomalies and take measures, transforming decision-making from experience-based to fact-based.

AI Scheduling Algorithm: Enabling the System to Judge and Make Decisions

- Core Function: Utilizing algorithms to calculate transportation routes, production rhythms, and task priorities in real time, achieving dynamic matching between production and construction needs.

- Operation Mode: The system uses data such as traffic conditions, vehicle locations, asphalt mixing plant output rates, and construction progress as input, and generates optimal vehicle dispatch and production plans through an AI model. For example, when road congestion is detected, the system automatically adjusts vehicle routes and reallocates mixing tasks to ensure uninterrupted material supply and prevent backlog.

- Changes Brought About: Scheduling decisions no longer rely on personal experience; instead, algorithms complete data analysis and task assignment within minutes. This model not only improves resource utilization but also gives the entire scheduling system self-learning capabilities—as project data accumulates, the system’s judgment becomes increasingly accurate.

Cloud-Based Collaborative Management: Enabling Synchronized Management

- Core Function: Centralizing all production and construction data to the cloud enables real-time collaboration across departments and regions.

- Operation Mode: Project managers, dispatchers, and owners can view progress data in real time through the same platform and monitor equipment operation and transportation status. The issuance, execution, and feedback of instructions are all updated synchronously in the cloud, ensuring that all participants make decisions based on the same data source.

- Changes Brought About: Construction management is no longer limited to the site. Managers can remotely monitor the project via computer or mobile device and adjust production and scheduling plans in real time. The cloud platform also records complete construction data for later quality traceability, energy consumption analysis, and performance evaluation.

When GIS+IoT handles real-time sensing, AI scheduling algorithms handle intelligent judgment, and cloud-based collaborative management handles unified execution, the three form a complete closed loop: data collection → intelligent analysis → decision execution → real-time feedback.

It is this multi-system collaboration that enables the information flow between production, transportation, and construction to be transmitted and adjusted within minutes, achieving a true transformation from manual instructions to data-driven processes.

Intelligent Scheduling in Practice: Boosting Asphalt Plant Construction Efficiency

The value of intelligent scheduling systems lies not only in their technical architecture but also in how they generate quantifiable improvements in real-world construction environments. Through practical application in multiple road construction projects, the system has significantly improved overall construction efficiency and resource utilization in key areas such as production matching, transportation scheduling, and on-site coordination.

The following three typical scenarios demonstrate its working logic and achievements in daily construction.

Scenario 1: Real-time Matching of Production and Paving Rhythm

- Application Background: In traditional models, asphalt mixing plants often rely on verbal feedback from construction teams to adjust output. Information delays can easily lead to paving delays or overproduction, affecting progress and material quality.

- System Mechanism: The intelligent scheduling system uploads asphalt paving machines operation data in real time, connecting to the asphalt mixing plant via IoT and the cloud. The system automatically compares paving speed, transport quantity, and production rate, adjusting the mixer discharge frequency and batch interval in real time in the background.

- Actual Results:

- Asphalt mixture supply is synchronized with paving progress, reducing on-site waiting time by approximately 30%.

- Production errors are significantly reduced, and asphalt aging and waste are virtually eliminated.

- Production plan adjustments are automated, requiring no manual intervention.

Scenario 2: Intelligent Vehicle Route Planning

- Application Background: In projects with multiple construction points and multiple transportation routes, manual vehicle dispatch often leads to transportation delays due to traffic changes or road congestion.

- System Mechanism: The AI scheduling algorithm automatically generates the optimal transportation route and scheduling sequence based on real-time road conditions, distance, and vehicle load. The system follows a first-in, first-out (FIFO) principle, dynamically allocating tasks in the background and pushing them to drivers in real time via mobile terminals.

- Actual Results:

- Average transportation time reduced by 15%–20%.

- Vehicle empty-run rate decreased by approximately 25%.

- Material arrival times are more even, resulting in a more stable paving rhythm.

Scenario 3: Multi-Site Collaboration and Remote Monitoring

- Application Background: Large-scale projects often utilize multiple asphalt mixing plants and paving teams simultaneously. Without unified scheduling, production imbalances or information silos can easily occur.

- System Mechanism: Through a cloud-based collaborative management module, production data, transportation status, and paving progress from different asphalt mixing plants are uniformly aggregated. Management can view the operational status of each station through a single platform, and the system automatically coordinates task priorities and balances resource allocation.

- Actual Results:

- Production rhythms of each station are automatically matched, resulting in a more balanced overall progress.

- Management can remotely monitor and issue adjustment instructions without on-site command.

- Significantly reduces coordination time and communication costs, improving overall project management efficiency.

In the past, construction scheduling was a reactive, responsive management approach—adjustments were made only after problems were discovered.

However, with the support of an intelligent scheduling system, scheduling has become a proactive optimization process. The system can predict and correct problems before they occur, ensuring that the operation rhythm of the asphalt mixing plant is always consistent with the construction site, truly achieving a highly efficient closed loop of production-transportation-paving.

Trends in Development: Advancing System-Level Intelligent Construction

The development of intelligent scheduling systems is driving asphalt mixing plants from partial automation to full-process digitalization. In future construction projects, it will not only be a tool, but also a core hub connecting design, construction, and operation and maintenance. Its evolution mainly focuses on the following three aspects:

Expanding Collaborative Scope: Upgrading from Single-Site Management to Regional Scheduling

- Cross-Project Data Interconnection Becomes a Trend: Future scheduling systems will achieve multi-site interconnection through cloud architecture and IoT devices. Data from different asphalt mixing plants, transport fleets, and construction sites will be centrally analyzed and scheduled on a single platform. This collaborative management model can break down project boundaries, enabling shared and dynamic allocation of production capacity.

- Optimized Regional Resource Allocation: When different projects are at different construction stages, the system can intelligently adjust production priorities based on real-time working conditions, achieving optimal combinations of equipment, personnel, and transport vehicles within the region. This will significantly improve equipment utilization and reduce resource idleness and redundant investment.

- Management Model Shifts from Project Units to Regional Networks: EPC contractors and large contractors will gradually build regional command centers, achieving cross-project collaboration and intensive management through intelligent scheduling platforms, forming a data-driven construction and operation system.

Upgrading Decision-Making Logic: From Real-Time Response to Predictive Scheduling

- AI Model-Driven Trend Prediction: Intelligent scheduling systems are moving from immediate adjustments to advance prediction. By accumulating historical production and transportation data, AI models can predict equipment operating status, traffic congestion risks, and project schedule fluctuations, thereby optimizing production and transportation plans before risks occur.

- From manual judgment to algorithm optimization: Previous scheduling relied on on-site experience, while future systems will automatically calculate the optimal solution based on data modeling and multi-factor analysis. This not only improves the scientific nature of decision-making but also reduces errors caused by human intervention.

- Forming an adaptive learning mechanism: The system will continuously optimize algorithm parameters during operation, constantly improving prediction accuracy through feedback mechanisms. Scheduling is no longer a static rule but a dynamic system that can learn and evolve.

Deepening system integration: Moving towards full lifecycle digital management

- Integration with BIM, GIS, and digital twin platforms: In the future, intelligent scheduling systems will no longer exist in isolation but will achieve data integration with design, construction, and operation and maintenance systems. Data such as asphalt mixing plant production records, transportation trajectories, and paving temperatures will be incorporated into BIM and digital twin models, supporting monitoring and maintenance throughout the road’s entire lifecycle.

- Extending from the construction phase to the operation and maintenance phase: Data no longer terminates after project completion but continues to support road maintenance, energy consumption assessment, and material traceability. This transforms road engineering from one-off construction to long-term asset management.

- Building an intelligent construction ecosystem: When the scheduling system is interconnected with modules such as project management, material tracking, and energy monitoring, a data-driven digital construction ecosystem will be formed. This not only improves the efficiency of individual projects but also lays the foundation for the sustainable development of the entire industry.

The future direction of intelligent scheduling is not only to make construction faster and more accurate, but also to reshape the operational logic of the entire construction management system. It will drive the road construction industry from experience-driven to data-driven, from phased optimization to full-cycle collaboration, and ultimately achieve a truly intelligent, transparent, and sustainable construction management model.

The intelligent scheduling system, through real-time data collection, AI optimization, and cloud collaboration, tightly connects the production, transportation, and construction sites of asphalt mixing plants, achieving efficient coordination and optimal resource allocation. This not only improves project timeline predictability and construction efficiency but also provides traceable data support for decision-making.

With technological maturity and the accelerated digitalization of the industry, intelligent scheduling will become the core engine of road construction projects, leading construction management from experience-driven to data-driven approaches, and from localized optimization to systemic collaboration, thus ushering in a new era of efficient, transparent, and sustainable construction.