In asphalt mixing plants, sand, gravel, mineral powder, and asphalt need to be continuously transported from the ground to the drying drum or mixing tower. This seemingly simple conveying process often significantly reduces production efficiency due to steep conveying angles and the tendency for materials to scatter.

Now, a conveying technology design called a skirt belt is changing all this. It makes the once challenging steep-angle conveying process efficient, safe, and stable, providing a solid guarantee for continuous production at asphalt mixing plants.

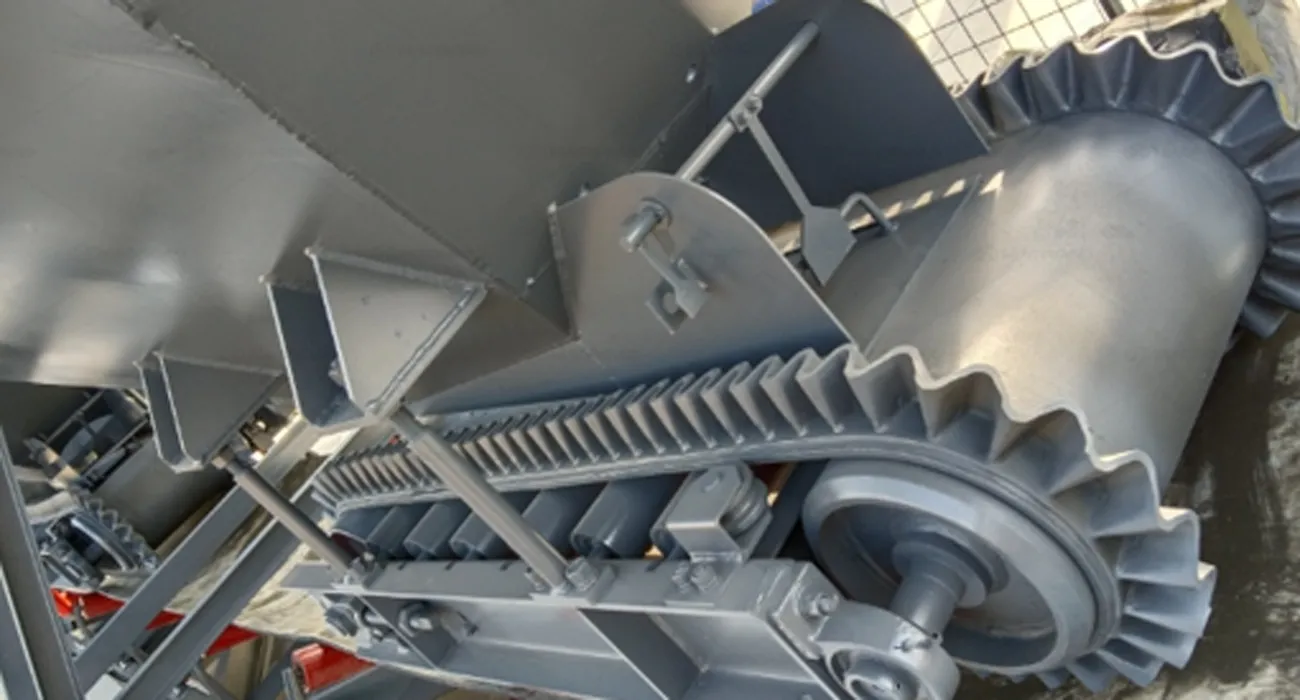

Skirted Belt: Engineered for Steep-Angle Conveying

A skirt belt is like a conventional conveyor belt equipped with guardrails and partitions. The guardrails prevent material from spilling, while the partitions divide the conveyor belt into small hoppers, ensuring stable material flow even at steep angles and near-vertical conveyance. This design makes it a highly effective tool in high-efficiency production environments like asphalt mixing plants, helping them achieve a balance between efficiency and safety.

The core design of a skirt belt includes:

- Side skirts: Act as guardrails to prevent material from spilling during conveying;

- Partitions: Divide the conveying surface into hopper-like sections. During operation, the material is trapped between the partitions and the side skirts, forming a relatively closed conveyor trough. This prevents material from slipping back during steep conveying, ensuring more stable conveying.

Leveraging this structural advantage, skirt belts play a vital role in multiple areas of an asphalt mixing plant:

| Cold material conveying: | Transporting sand and gravel aggregates of varying specifications from the cold material silo to the drying drum. |

| Mineral powder conveying: | Safely and quickly lifting mineral powder to the mixing plant in a relatively closed environment. |

These applications not only address the problems of traditional conveyor belts, such as material spillage, large footprint, and low efficiency during high-angle transport, but also enhance production continuity and space utilization in asphalt mixing plants. Skirt belts are an indispensable conveying tool in asphalt mixing plants, helping production lines achieve greater efficiency and stability within limited space.

Efficiency & Stability Boost: The Unique Advantages of Skirted Belts

Traditional flat conveyor belts have long been used in asphalt mixing plants for material transport. However, with increasing demands for production efficiency, space utilization, and environmental protection, their limitations are becoming increasingly apparent: high-angle conveying leads to slippage, significant material spillage, large floor space requirements, frequent maintenance, and limited adaptability. In contrast, skirt belts, with their unique structural design, offer significant advantages in multiple areas, making them a key choice for modern mixing plant conveying systems.

High-Angle Conveying for Higher Efficiency

- Traditional conveyor belts: Inclinations generally do not exceed 18°. Larger angles can easily cause material backflow and interruptions.

- Skirted conveyor belts: They can achieve large angles from 0° to 90°, even vertically, making them suitable for climbing slopes or vertical lifts. This not only improves conveying efficiency but also saves plant space.

- Technical Value: The collaborative design of the skirts and center baffles ensures material stability during conveying, reducing downtime and blockages even under high loads. Actual operating conditions show a 15%-30% increase in conveying efficiency.

Closed design minimizes material loss

- Traditional conveyor belts: Material is prone to spillage during high-angle or high-speed operation, increasing cleanup costs.

- Skirted conveyor belts: The combination of side skirts and baffles creates a relatively closed conveying trough, virtually preventing material leakage.

- Advantages: They not only reduce material waste but also reduce dust pollution, helping the batching plant meet environmental standards.

Improved space utilization and layout flexibility

- Traditional conveyor belts: Horizontal or gently sloping conveying requires long aisles and occupies a large area.

- Skirt Belt: Its three-dimensional conveying design enables wide-angle or vertical conveying within limited space, making the mixing plant layout more compact.

- Application Value: In small factories or multi-line production scenarios, skirt belts enable more efficient production line layout and improve overall capacity utilization.

High Adaptability and Reliability

- Traditional conveyor belts: Made of a single material, they are susceptible to wear and failure in high-temperature, high-dust environments.

- Skirt Belt: Available with heat-resistant and wear-resistant materials, and featuring reinforced baffles for rugged operation.

- Effect: Ensures long-term, continuous, stable operation, minimizing production downtime caused by environmental or operating condition fluctuations.

Reduced Maintenance and Operating Costs

- Traditional conveyor belts: Frequent material spillage and backflow require regular cleaning and maintenance.

- Skirt Belt: Stable conveying reduces downtime, while the wear-resistant and heat-resistant material extends its service life.

- Long-Term Value: Reduces maintenance and replacement frequency, significantly reducing the operating costs of the entire conveyor system.

Comparing traditional conveying methods with the use of skirt belts reveals significant advantages in high-angle conveying, material control, space utilization, adaptability to complex working conditions, and reduced maintenance costs. Not only does it address the challenges of traditional conveying, but it also provides a solid foundation for continuous asphalt production at asphalt mixing plants through efficient, stable, and reliable conveying.

Common Models & Selection Guide: Perfectly Matching Skirted Belts with Asphalt Plants

In asphalt mixing plants of different types and capacities, the specifications and material selection of the skirt belt are crucial. The appropriate selection not only affects the conveying efficiency, but also the long-term operating costs of the equipment. The following dimensions can be used for reference:

Select by Conveyor Belt Width

- 40-80cm width: Suitable for small or medium-sized asphalt mixing plants, such as those with a capacity of 40-80 t/h;

- 80-120cm width: Suitable for medium-to-large asphalt mixing plants, such as those with a capacity of 100-160 t/h;

- 120cm and above width: Suitable for large, continuous production lines with a capacity of 200 t/h or more.

Select by Conveyor Angle

- Up to 30°: Standard skirt belts will suffice;

- 30°-60°: Choose a skirt belt with a high baffle design to prevent material from slipping;

- 60°-90°: Choose a specialized high-angle or near-vertical skirt belt structure, requiring higher baffle strength.

Select by Conveyor Material Characteristics

- For high-temperature materials: Choose a high-temperature-resistant rubber or metal-reinforced skirt belt;

- For dusty materials: A closed skirt belt with improved sealing is recommended to reduce dust leakage;

- For high-wear materials: Choose a wear-resistant rubber to extend service life.

Select by production line layout

- Compact site: Prioritize high-angle conveying solutions to reduce horizontal conveying footprint;

- Peak production capacity: Select wider conveyor belts and high-strength partition structures to ensure efficient conveying.

Maintenance & Lifespan Management: Key to Extending Skirted Belt Service Life

Although the structure and material of the skirt belt have been optimized for the complex working conditions of the asphalt mixing plant, reasonable maintenance and management are still the key to ensure its long-term stable operation. The following suggestions can help users extend the service life of the equipment and reduce downtime:

Regular Tensioning and Deviation Inspection

- Inspection Frequency: It is recommended to check conveyor belt tension and deviation weekly.

- Adjustment Method: If conveyor belt deviation is detected, adjust the tensioner or roller position promptly to prevent excessive wear due to friction.

Conveyor Surface and Skirt Cleaning

- Cleaning Tools: Use a dedicated sweeper or flexible scraper; avoid direct contact of metal tools with the conveyor surface.

- Cleaning Frequency: When there is a large amount of sticky material, clean the belt daily to minimize damage to the baffles and skirts caused by material accumulation.

Appropriately Control Conveyor Volume and Speed

- Excessive conveyor volume: Excessive stress on the skirt baffles can occur, shortening their service life.

- Excessive speed: Increased material impact force can lead to increased wear on the conveyor surface. The speed and load should be appropriately set according to design parameters.

Pay Attention to Wear and High-Temperature Resistance

- Applicable Scenario: When conveying high-temperature, high-abrasion materials, choose a skirt belt with a high-temperature and wear-resistant rubber compound.

- Protective Measures: Cooling or insulation devices can be installed in high-temperature areas to prevent premature aging of the conveyor belt due to excessive temperatures and extend its service life.

Spare Parts and Preventive Maintenance

- Spare Parts Allocation: It is recommended to have a sufficient number of spare parts, such as partitions and skirt sections, to facilitate timely replacement when worn or damaged, thus minimizing production downtime.

- Drive System Maintenance: Regularly inspect, lubricate, and tighten the transmission components of the conveyor system to prevent indirect damage to the skirt belt due to transmission failures.

Recording and Analyzing Operational Data

- File Creation: Detailed records are maintained of the conveyor belt’s operating time, maintenance status, and replacement cycles.

- Optimization Strategies: By analyzing operational data, a rational maintenance and replacement plan is developed to improve equipment efficiency and lifespan.

Regular inspections and operational status analysis of the skirt belts ensures stable and efficient operation. Scientific maintenance not only reduces downtime risks but also extends the service life of the conveyor belt, making the asphalt mixing plant production line more reliable and sustainable.

Details Reflect Strength: Evaluating Supplier Quality Through Skirted Belts

In an asphalt mixing plant, the skirt belt is just a small component of the conveying system, easily overlooked. Yet, this small detail often reflects the asphalt plant supplier‘s technical depth and management level. The reason is simple:

- Design: Excellent suppliers will select the appropriate material and structure based on the plant’s capacity, material characteristics, and operating conditions to avoid common problems such as spillage and blockage. Macroad also fully considers different capacity and operating conditions in its skirt belt design, providing customers with customized solutions to ensure stable and efficient conveying.

- Quality: Even a seemingly ordinary skirt belt’s material formulation, process control, and wear resistance are the result of the supplier’s production management and quality system. Macroad rigorously tests each skirt belt to ensure long-term reliability.

- Professional service: From selection guidance, delivery time, and after-sales response, the delivery experience of a small component often reflects the supplier’s overall service capabilities. Macroad provides integrated services from on-site assessment to installation guidance, ensuring peace of mind for customers.

- Technological Foresight: Suppliers with expertise in intelligent monitoring, new materials, and environmentally friendly design are often more competitive in overall asphalt mixing plant solutions. Macroad continuously invests in R&D to provide customers with high-temperature and wear-resistant skirting solutions to meet your needs.

So, don’t underestimate a skirting. It’s these seemingly insignificant details that determine a supplier’s ability to truly deliver value in the face of large-scale projects and high-capacity production. Choosing a professional asphalt mixing plant supplier like Macroad ensures reliable assurance in every detail.

FAQs

What materials are suitable for conveying with skirted belts?

How should I choose the material for the skirt belt?

What is the typical service life?

What is the approximate price of a skirt belt?

How often should maintenance and cleaning be performed?

In the vast production chain of an asphalt mixing plant, the skirt belt is a seemingly insignificant component, yet it plays an irreplaceable role in ensuring stable conveying and improving production efficiency. This demonstrates that a truly excellent supplier demonstrates not only strength in core equipment but also professionalism and responsibility in every detail. In the future, with the continuous advancement of intelligent and environmentally friendly technologies, these details will no longer be mere component optimizations, but will become the cornerstone of the entire production system’s journey towards efficiency, intelligence, and sustainable development.