Full Chain Solution For Asphalt Plant in Australia

Strategic Partner of Fortune Global 500 Companies

In recent years, road construction projects in Australia have continued to advance, from highways and airport roads to urban roads and transportation routes in remote areas. The requirements for road surface construction have also become increasingly demanding. Different construction scenarios have led to more practical demands regarding the stability, continuous supply, and environmental control of asphalt plant for sale Australia.

At specific construction sites, these requirements often translate into higher expectations for the stability and production pace of asphalt supply. In this construction environment, asphalt material production has become a crucial factor affecting construction progress and road quality. Stable and controllable asphalt production capabilities help construction teams better cope with different project conditions, making asphalt mixing plants increasingly indispensable basic asphalt equipment for sale Australia in road construction.

Key Construction Scenarios in Australian Road Projects

Asphalt equipment for sale Australia do not serve just one type of road project, but are widely used in various transportation and infrastructure construction projects. From national highways and urban roads to connecting projects in remote areas, different types of projects, although varying in construction conditions, all rely on a stable supply of asphalt mix. The following are the main application scenarios for asphalt plant for sale Australia in current and planned road construction projects.

Highway and National Transportation Trunk Line Construction Projects

Australian highway and national transportation corridor construction projects have long construction cycles and cover vast distances, making them a major area of asphalt plant for sale Australia. Typical projects include:

- Pacific Highway Upgrade: Covering multiple sections in New South Wales, involving long-term phased construction and road surface upgrades.

- Bruce Highway Upgrade Program: A major transportation artery in Queensland, the project includes road widening and structural reinforcement.

- Hume Highway Corridor Improvements: An important interstate corridor connecting New South Wales and Victoria.

- Princes Highway Upgrade Projects: Involving continuous upgrading and maintenance of multiple road sections in coastal areas.

Urban Roads and Municipal Transportation Infrastructure Projects

Urban road projects are numerous and widely distributed, making them an important area for the continuous application of asphalt plant for sale Australia. Typical projects include:

- WestConnex Project (Sydney Western Transport Hub Project): Includes extensive urban road and connecting road construction and pavement engineering.

- North East Link (Melbourne North East Link Project): As a major urban transportation improvement project, it involves the construction of multiple municipal roads.

- Parramatta Road Upgrade: A long-term renovation project of a core urban artery in Sydney.

- Melbourne Suburban Road Upgrade Programs: Covering road resurfacing projects for multiple urban main roads and branch roads.

Airport Roads and Heavy-Duty Traffic Pavement Projects

Airport pavements and heavy-duty traffic areas require high-quality and durable road surfaces. Relevant typical projects include:

- Western Sydney International Airport: Involving large-scale pavement construction for taxiways and supporting roads.

- Brisbane Airport Airside Upgrade Projects: Including internal airport road engineering.

- Perth Airport Runway and Taxiway Works: Focusing on pavement construction under heavy-duty traffic conditions.

- Port of Melbourne Road Infrastructure Works: Heavy-duty pavement projects serving port and logistics transportation.

Road Construction in Remote Areas and Resource Projects

Road construction in remote areas and resource development projects typically involves complex construction environments and a high reliance on on-site or nearby asphalt production capabilities. Typical projects include:

- Pilbara Region Mining Access Roads: Providing road infrastructure support for mining transportation in Western Australia.

- Galilee Basin Infrastructure Roads: Serving as transportation connections for resource development areas.

- Northern Territory Remote Access Road Programs: Covering multiple remote communities and regional transportation corridors.

- Queensland Regional Resource Roads: Connecting mining areas, industrial facilities, and major transportation networks.

Road Maintenance and Phased Repair Projects

In addition to new construction projects, Australian states continuously undertake road maintenance and repair projects. Typical projects include:

- State Road Maintenance Programs: Covering periodic resurfacing of highways and major arterial roads.

- Urban Road Resurfacing Projects: Phased maintenance construction for high-traffic roads.

- Regional Highway Rehabilitation Works: Improving existing road structures and driving safety.

- Night-Time Road Repair Programs: Rapid repair projects aimed at minimizing traffic disruption.

Practical Experience Across Global Projects

In road construction projects across different regions, the construction environment, project scale, and operating conditions often vary significantly. Based on these diverse construction scenarios, Macroad has gradually accumulated practical experience in handling complex working conditions while serving various client projects. It is precisely this feedback from actual engineering projects that has led to continuous optimization of the asphalt mixing plant’s equipment configuration and operating procedures, enabling it to better adapt to different project conditions and providing a basis for selecting the appropriate asphalt hot mix plant for specific road engineering projects.

Precision Partner for Bridge Construction — ALQ80 in Myanmar’s Gyaing Zathapyin and Atran Bridges Project

- Capacity: 80tph

- Site Manager: The ALQ80’s high-precision weighing system ensured accurate concrete and asphalt ratios, significantly improving efficiency, allowing the team to maintain consistent quality even under tight deadlines.

Accuracy Comes First — ALQ80 Meeting Kyrgyzstan’s Strict Weighing Standards

- Capacity: 80tph

- Quality Control Supervisor: Throughout construction, the ALQ80’s weighing accuracy fully met Kyrgyzstan’s strict standards, greatly reducing material waste and enhancing control over paving operations.

Continuous Operation Assurance — ALT80’s Performance in Malaysia

- Capacity: 80tph

- Field Engineer: The ALT80 operated continuously for weeks in Malaysia’s hot and humid conditions with minimal interruptions, providing reliable support for on-schedule project completion.

Mobility for Efficient Construction — ALYT80’s Advantage in Bosnia Project

- Capacity: 80tph

- Project Coordinator: The ALYT80’s fast mobility and easy setup allowed us to shift between multiple sites, saving significant time and manpower, making project scheduling much more flexible.

Reliable Choice for Urban Roads — ALQ120 Supporting Jamaican Municipal Project

- Capacity: 120tph

- Municipal Project Supervisor: The ALQ120 performed steadily in urban road construction, delivering accurate mix ratios and smooth operation, significantly improving efficiency while ensuring road quality.

Asphalt Plants Precisely Tailored for Australia

Facing the diverse road construction needs in Australia, different projects exhibit significant variations in construction scale, working conditions, and construction organization methods. Based on an understanding of these practical project conditions, Macroad offers types of asphalt plants, covering different application scenarios such as stationary, mobile, and continuous production, helping your project team select the most suitable equipment type based on their specific needs.

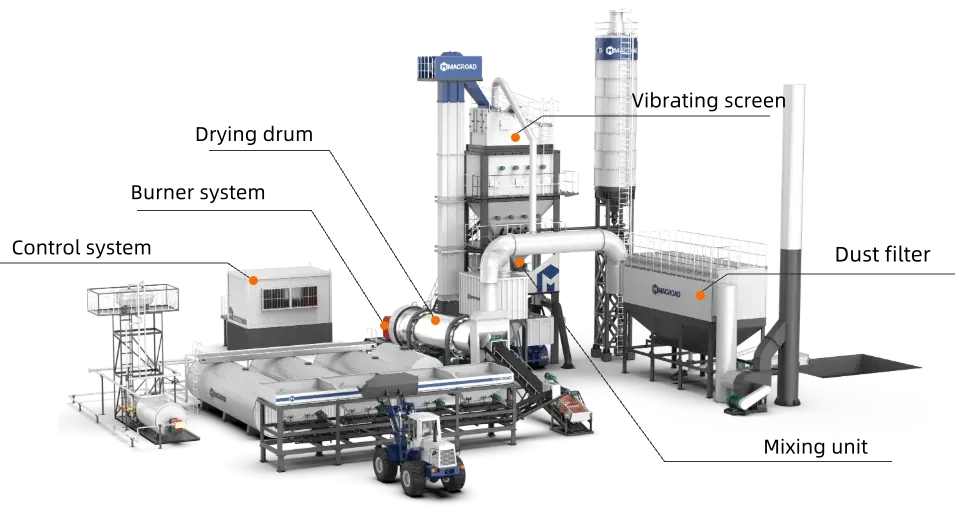

ALQ Series Stationary Batch Asphalt Mixing Plant

- Equipment Features: The ALQ series asphalt batching plant adopts an intermittent production method, allowing for precise control of the asphalt, aggregate, and mineral powder ratios. It is suitable for road engineering projects with high requirements for mix quality. The equipment has a stable structure and controllable operating rhythm, supporting long-term, continuous construction schedules.

- Suitability for Australian Working Conditions: In Australian highway, airport road, and heavy-duty road projects, construction standards are generally high. The stable production capacity and excellent ratio control of the ALQ series help meet the requirements for pavement quality consistency in such projects, making it suitable for long-term, large-scale road construction projects.

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

ALYQ Series Mobile Batch Asphalt Mixing Plant

- Equipment Features: While retaining the advantages of intermittent production, the ALYQ series mobile asphalt batching plant features good mobility and modular design. The equipment can be quickly installed and relocated according to project needs, achieving 24-hour rapid relocation and reducing preparation time.

- Suitability for Australian Working Conditions: Given the dispersed project sites and flexible construction cycles in some Australian projects, the ALYQ series is suitable for municipal roads, regional renovation projects, and phased construction projects. It can quickly switch between different construction sites, improving overall construction efficiency.

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

ALT Series Stationary Drum Asphalt Mixing Plant

- Equipment Features: The ALT series drum mix type stationary asphalt mixing plant adopts a continuous production mode, with a relatively simplified structure and high production efficiency, suitable for construction needs requiring long-term, uninterrupted operation. This series performs well in energy consumption control and operational stability, suitable for continuous production of large quantities of asphalt mix.

- Suitability for Australian Working Conditions: In long-distance low-grade road construction and large-scale road upgrade projects in Australia, the ALT series can meet the requirements for output and stability in continuous construction, helping projects maintain construction progress while controlling operating costs.

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

ALYT Series Mobile Drum Asphalt Mixing Plant

- Equipment Features: The ALYT series mobile asphalt drum mix plant combines the efficiency advantages of continuous production with the flexibility of a mobile structure. The equipment has a compact layout and is easy to relocate, suitable for projects requiring frequent changes of construction sites.

- Suitability for Australian Working Conditions: For road construction in remote areas, roads supporting resource projects, and temporary construction access roads, the ALYT series can be deployed and put into production in a relatively short time, reducing reliance on external asphalt supply and better adapting to the complex and ever-changing construction environment in Australia.

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

Through a detailed introduction to the four major series—ALQ, ALYQ, ALT, and ALYT—it is clear that Macroad’s asphalt mixing plants possess a systematic advantage in adapting to the diverse needs of projects in Australia. Whether it’s precise control over road construction quality or high standards for construction flexibility and continuous production capacity, each series of equipment can be specifically matched and optimized for actual working conditions.

These capabilities are not the result of experience accumulated from a single project, but rather stem from Macroad’s long-term service to road engineering projects in different countries under varying construction conditions. From bridge engineering and municipal roads to highways and airport infrastructure projects, the equipment has continuously operated under diverse climatic environments, construction standards, and operational intensities, gradually forming a mature design logic and configuration experience. This allows Macroad to quickly transfer and adapt mature solutions to the Australian market, ultimately providing stable, efficient, and sustainable asphalt mixing plant solutions for various road engineering projects in Australia.

Equipment Optimization for Australian Project Conditions

Macroad’s ALQ, ALYQ, ALT, and ALYT series, supplied for Australian road projects, can cover a wide range of construction needs, from fixed large-scale projects to remote mobile construction sites. While these series asphalt plant for sale Australia provide an overall framework for the projects, the true guarantee of stable asphalt production capacity lies in the targeted optimization of each system’s design—every aspect is considered to adapt to varying construction conditions and stringent engineering standards.

Characteristics of Australian Working Conditions

The construction environment for road engineering in Australia has its unique characteristics, mainly reflected in the following aspects:

- Significant variations in climate conditions: The northern tropical regions experience frequent rainy seasons and high humidity; some southern regions have cold winters, affecting construction continuity.

- Numerous remote and isolated construction sites: Mining areas, remote communities, and resource-related road construction require on-site or nearby asphalt production capabilities.

- Strict environmental protection and approval requirements: Environmental regulations such as those from the EPA have clear requirements for emissions and measurement data, affecting construction material management.

- High construction standards and strict quality requirements: Highway, airport runway, and heavy-duty pavement projects demand high uniformity of the road surface and stability of the mix quality.

In response to these characteristics, Macroad’s six systems have been optimized in their design to ensure that the asphalt plant for sale Australia can still operate efficiently and stably under different project conditions.

| Typical Australian Construction Conditions | Corresponding System | Targeted Optimization Design |

| High humidity and frequent rainfall during wet seasons, causing aggregate moisture variation and unstable feeding (e.g. Queensland) | Cold Aggregate Feeding System | Supports precise weighing and simultaneous feeding of 3–5 aggregate types, equipped with automatic belt alignment, material shortage alarms, and maintenance platforms. PLC control automatically matches production rhythm, ensuring stable and continuous feeding even under wet material conditions. |

| Large variation in aggregate moisture content and changing climate conditions, requiring stable drying efficiency and uniformity | Drying System | Optimized drum blade and material curtain design improves heat exchange efficiency. Burner pipelines feature automatic purging, while selected models support heat recovery and intelligent temperature control to ensure uniform drying under varying moisture levels. |

| Strict environmental approval processes requiring reliable and traceable production and mix proportion data | Weighing System | Dynamic secondary weighing correction technology is applied. Powder screw conveyors are directly connected to the mixer, reducing discharge and mixing time. Electronic weighing records support digital management and EPA compliance. |

| High-temperature, high-humidity, or high-intensity working conditions requiring consistent mix quality and uniformity | Mixing System | Twin-shaft compulsory mixing structure with upgraded wear-resistant components, combined with IoT-based real-time monitoring of mixing paths, ensures stable and uniform asphalt mixture quality suitable for highways and airport projects. |

| Stringent environmental regulations with strict requirements on dust emissions and operational safety | Dust Collection System | Multi-stage filtration system with flue over-temperature protection. Factory-tested emission performance exceeds international environmental standards, while flexible ducts and adjustable flanges improve on-site installation adaptability. |

| Remote project locations with limited operators, requiring high automation and remote support capability | Control System | Integrated display and IoT modules support one-button start/stop, remote commissioning, and multiple operation modes. Digital monitoring of equipment status reduces reliance on skilled operators and shortens training cycles. |

Through the optimized design of six core systems, Macroad asphalt mixing plants demonstrate their capability in handling diverse construction environments in Australia: from aggregate supply and drying treatment to precise metering, uniform mixing, environmentally friendly emissions, and digital control, every aspect has been specifically optimized to adapt to conditions such as rainy seasons, high temperatures, remote construction sites, and strict environmental standards. It is these system-level designs that enable different series of asphalt equipment for sale Australia to maintain high efficiency and stability in actual asphalt production, providing reliable support for project teams.

Choosing the Right Asphalt Plant for Australian Projects

You may have already read introductions to various asphalt mixing plants and understand the advantages and technical features of different equipment series. However, when facing the diverse construction environment in Australia, you may still be unsure which equipment is best suited for your project. Different regional climates, construction scales, road standards, and environmental approval requirements can all influence equipment selection. Based on these core influencing factors, when selecting an asphalt mixing plant for Australian projects, you should focus on its suitability for the construction type, environmental compliance, production stability, and long-term operating costs, and then conduct a systematic screening and decision-making process. To help project teams more accurately match construction needs, we have compiled this equipment selection guide for Australian working conditions.

Clearly Define Your Project Requirements

Clearly defining the core requirements of your project is the first step in choosing the right asphalt plant for sale Australia. Only by clearly understanding the specific needs of the project can you accurately match the most suitable equipment.

- Determine project scale: First, you need to assess the scale of the project, especially large-scale road construction projects such as highways and airports, which have high requirements for equipment output and stability. Therefore, it is suitable to choose fixed equipment that can provide continuous production and high stability.

- Evaluate accuracy and proportioning requirements: Some special projects, such as airport runways, have high requirements for asphalt accuracy, requiring the selection of high-precision equipment. Forced-mixing equipment usually provides higher proportioning accuracy and stability.

- Evaluate production capacity requirements: Secondly, you need to confirm the production capacity required for the project. Large-scale projects require high-capacity equipment, while small-scale municipal engineering projects can choose equipment suitable for short-term, efficient production.

Evaluate the Special Requirements of the Construction Environment

Different regions of Australia have different climates and construction environments, which have a significant impact on the selection of asphalt plant for sale Australia. Choosing equipment that adapts to specific environmental conditions can ensure the stability of the construction schedule.

- Dealing with humid environments: The northern regions have high humidity, so choosing equipment with an optimized drying system is crucial. The equipment needs to effectively dry wet aggregates to avoid production interruptions caused by humidity.

- Adapting to hot and cold weather: Southern cold regions may experience low temperatures affecting equipment operation. Choosing asphalt plant for sale Australia equipped with temperature control and waste heat recovery systems can ensure stable operation in cold weather.

- Construction in remote areas: In remote areas, transportation and logistics conditions are poor. Choosing equipment that is easy to transport and has a modular design will reduce the complexity of on-site installation and facilitate rapid deployment.

Combine Construction Period and Production Model

The length of the construction period directly affects the choice of equipment production model, and it is crucial to ensure that the equipment can efficiently complete the work within the specified time.

- Stability for long-term projects: For projects that require long-term continuous construction, batch mix or drum mix asphalt plant for sale Australia can provide higher stability and continuous production capacity.

- Flexibility for short-term projects: For time-sensitive municipal engineering or small-scale projects, choosing flexible mobile equipment is more suitable. Mobile equipment can be quickly deployed, adjust the production pace, and reduce uncertainties during the construction process.

- Adjustable production model: Some project construction needs may change at any time, such as site conditions or material types. At this point, choosing equipment that can automatically adjust operating parameters is crucial. It can quickly adapt to actual site conditions, ensuring efficient production and preventing delays caused by variations that could impact project progress.

Ensuring Compliance with Environmental Requirements and Approval Processes

In Australia, environmental standards are very strict. Choosing equipment that meets environmental requirements not only helps improve approval efficiency but also avoids project delays due to environmental non-compliance.

- Emission Standards: Choosing asphalt plant for sale Australia that meets EPA emission standards is very important. The equipment needs to be equipped with an effective exhaust gas filtration system to ensure that emissions comply with environmental regulations and avoid project delays.

- Automatic Measurement and Reporting Functions: The equipment’s automatic measurement system can accurately record the proportion data of asphalt and aggregates and automatically generate electronic reports that meet environmental requirements. This can accelerate the approval process and avoid problems caused by human error.

- Pre-approved Environmental Testing: Equipment that has undergone environmental testing and obtained certification in advance can reduce repeated communication regarding emissions during the later approval process, ensuring the smooth start of the project.

Evaluating Equipment Production Capacity and Maintainability

The production capacity of the equipment and the ease of maintenance directly affect the smooth progress of the project. Choosing equipment that suits the project needs can not only improve production efficiency but also reduce equipment failures and maintenance costs.

- Equipment Capacity Matches Project Needs: Evaluate whether the equipment’s capacity matches the scale and duration of the project. Large-scale projects require high-capacity equipment, and stationary equipment is usually suitable for long-term, stable, high-load production.

- Maintainability: The maintenance cost and difficulty of the equipment are also important factors to consider for long-term projects. Choosing equipment that is easy to repair and has a modular design can ensure efficient operation after long-term use and reduce downtime.

- Ease of Operation: Is the equipment’s operating system simple and intuitive? Equipment equipped with an automated control system can reduce the workload of operators, simplify operating procedures, and avoid human errors.

Comprehensive Budget and Cost-Benefit Analysis

Finally, budget and cost-effectiveness are factors that cannot be ignored when choosing an asphalt mixing plant. A reasonable asphalt mix plant price can help you maximize the use of funds while ensuring project needs are met.

- Initial Investment and Long-Term Operating Costs: When choosing asphalt plant for sale Australia, you need to weigh the initial investment against the long-term operating and maintenance costs based on the project budget. Although stationary equipment has a higher initial investment, from a long-term operating perspective, its stability and low maintenance costs are often more cost-effective.

- Return on investment during the project lifecycle: Large-scale projects have longer return on investment periods for equipment, while short-term projects focus more on short-term returns. Flexible, mobile equipment can meet this need.

- Budget flexibility: Equipment selection can be flexibly adjusted based on the actual project situation and budget. For projects with limited budgets, choosing mobile or intermittent asphalt plant for sale Australia can effectively reduce initial investment.

Choosing the right asphalt mixing plant is crucial to meeting the needs of your Australian projects. Whether it’s high-efficiency production capacity, environmentally friendly emission standards, or designs adaptable to diverse construction environments, Macroad’s asphalt mixing plants precisely meet these requirements. Choosing Macroad means choosing not only high-quality equipment but also a reliable partner to help you successfully complete every project and achieve the best return on investment.

High-Performance Asphalt Plants Fully Compliant with Australian Standards

After selecting the asphalt equipment for sale Australia, the next crucial consideration is whether the equipment meets Australia’s stringent construction and environmental standards. Australia has numerous certification requirements for asphalt mixing plants, covering aspects such as production accuracy, emission standards, and ease of installation. Macroad’s asphalt mixing plants are designed and engineered with these requirements in mind, ensuring that they meet the standards and needs of various Australian projects, from high-precision weighing and environmentally friendly dust control to flexible installation, providing customers with reliable construction assurance.

Patent and Certification Compliance

- Standard Requirements: Australian construction standards require equipment to be reliable and safe, and to meet international certifications (CE) or equivalent technical specifications to ensure that the equipment does not experience safety or performance problems during transportation, installation, and operation.

- Macroad Advantages: High-integration asphalt equipment for sale Australia, mobile drum mixer patents, pipeline expansion technology, and CE certification ensure that the equipment fully meets Australian technical and safety requirements in terms of structural stability, intelligent operation, and transportation and installation safety.

- Benefits: Ensures safe and reliable construction, stable equipment during transportation and installation, smooth approval process, and reduced risk of construction interruptions.

Dust Removal System Adaptability

- Standard Requirements: The Australian EPA has strict requirements for dust emission limits, with on-site emissions required to be ≤50mg/m³. The dust removal system must also remain stable under continuous high-production conditions, with a bag life of no less than 2000 hours.

- Macroad Advantages: The primary cyclone dust collector significantly improves dust separation efficiency, and the secondary bag filter (ALQ80 bag area 384㎡) ensures stable emission control even under continuous high production.

- Benefits: Emissions consistently below standard limits, reduced maintenance frequency and downtime risk, and extended dust removal equipment lifespan, improving project operational efficiency.

Installation and On-site Adaptability

- Standard Requirements: Australian construction specifications require a maximum allowable deviation of ±3cm for equipment installation, and an allowable error of ±5° for pipe and duct installation angles, to ensure on-site safety and normal equipment operation.

- Macroad Advantages: The telescopic pipe design in asphalt equipment for sale Australia allows for a ±3cm installation error, and the air ducts use a movable flange design, allowing for rotational angle adjustment, providing strong on-site installation adaptability.

- Benefits: Reduces on-site installation difficulty, reduces construction time and rework risks due to installation deviations, and improves the rapid deployment capability of the equipment.

High-Precision Weighing System

- Standard Requirements: Australian road construction standards require aggregate weighing accuracy within ±2%, and powder and asphalt weighing accuracy within approximately ±1.5%, to ensure that the mixed material quality meets highway and runway construction standards.

- Macroad Advantages: The aggregate scale has a maximum weighing capacity of 1100KG, with a dynamic accuracy of ≤±1.5% and a static accuracy of ≤±0.5%; the powder scale has a maximum weighing capacity of 150KG, with a dynamic accuracy of ≤±1.5% and a static accuracy of ≤±0.3%; the asphalt scale has a maximum weighing capacity of 100KG, with a dynamic accuracy of ≤±1.5% and a static accuracy of ≤±0.3%, fully meeting Australian standard accuracy requirements.

- Benefits: Ensures accurate mix proportions, guarantees construction quality and product consistency, facilitates data recording and approval processes, and reduces the risk of rework.

Macroad’s asphalt equipment for sale Australia are designed and engineered with full consideration of Australian construction and environmental standards. From high-precision weighing and stable dust control to flexible installation and structural safety, every design aspect closely adheres to local regulations. This not only guarantees construction quality and product consistency but also provides reliable assurance for project approval and daily management, allowing you to complete various road construction projects with peace of mind and efficiency.

The Ideal Asphalt Plant Partner for Australian Projects

Combining years of global experience with optimized design for Australian operating conditions, Macroad asphalt equipment for sale Australia provide reliable, intelligent, and efficient solutions for various road construction projects. Whether it’s highways, airport runways, or municipal roads, each piece of equipment is meticulously designed and rigorously tested to ensure stable and efficient operation during construction and consistent product quality. With high-precision weighing systems, advanced dust removal technology, and flexible installation design, Macroad helps clients easily overcome various construction challenges while reducing maintenance costs and risks.

Choosing Macroad means choosing not only high-performance asphalt equipment for sale Australia but also a trustworthy partner, bringing a robust and efficient construction experience and significant return on investment to Australian road projects. Fill out the form below to let our professional team contribute to your project and help you successfully complete your road construction projects.