Smart Control, Efficient Production

24-hour Rapid Transfer

Many construction projects suffer delays and increased costs due to lengthy equipment relocation and installation periods, especially for cross-regional construction or temporary sites. Mobile asphalt plant is designed to address this issue. They are not only quick to assemble and disassemble but also adaptable to different terrains and site conditions, enabling rapid on-site production. Choosing an asphalt plant mobile means construction is no longer limited by equipment, resulting in more efficient project startup and more flexible site relocation.

Mobile asphalt mixing plant applicable projects

In road construction projects, site changes often outpace plans: tight schedules, shifting locations, and complex environmental conditions. In such situations, the ability of construction equipment to quickly adapt to the project pace directly impacts progress, cost, and customer satisfaction.

Mobile asphalt mixing plant is designed to address this uncertainty. They offer flexible relocation and rapid commissioning, providing a stable and reliable asphalt supply to projects and helping you efficiently complete construction tasks in any environment.

| Highway and Expressway Construction: | Highway projects are often constructed in sections with tight schedules for each section. Mobile asphalt plant can be quickly moved to different construction sites, and the time required for dismantling, assembly, and restarting is significantly shorter than that of stationary asphalt mixing plants. This ensures that equipment is not idle, provides a stable and reliable asphalt supply, guarantees continuous project progress, and saves on transportation and waiting costs. |

| Municipal Roads and Urban Renewal/Expansion Projects: | Urban construction sites are limited, approval processes are complex, and the construction environment is restrictive. Asphalt mixing plant mobile have a small footprint and flexible deployment, allowing for rapid deployment even in confined spaces. Whether in busy streets or narrow sections, they can quickly produce asphalt, minimizing disruption to urban traffic and the surrounding environment, while ensuring that construction progress is not affected by site limitations. |

| Rural Roads and Regional Connector Construction: | Rural roads and regional connectors often involve scattered construction sites with inconvenient transportation. Stationary asphalt mixing plants require high investment and have difficult returns. Asphalt mobile plant can be flexibly deployed according to project needs, producing asphalt close to the construction site, saving on long-distance transportation costs, improving construction efficiency, and making more rational use of resources at scattered construction sites. |

| Temporary Road Repair and Emergency Engineering: | Sudden events or natural disasters may damage roads, requiring a large supply of asphalt in a short period. Mobile asphalt plant require no complex foundation construction, can quickly enter the site and immediately begin production, enabling rapid emergency response. Construction teams can restore road traffic in the shortest possible time, ensuring the efficient completion of emergency projects. |

Client Stories for Mobile Asphalt Plant

Beyond Expectations: ALYT80 That Meets the Toughest Standards

- Capacity: 80tph

- Project Feedback: We were initially worried that an imported plant wouldn’t meet Bosnia’s strict asphalt quality standards, but the ALYT80 exceeded all expectations. It not only met but stabilized the mix like never before.

From Setup to Profit: A Result-Driven Asphalt Solution

- Model: ALYT100

- Project Investor: We expected to see returns in six months, but it paid back in just three. The plant runs smoothly with minimal maintenance costs — a true high-ROI investment.

Tough Terrain, Reliable Supply: ALYT80 Built for Remote Projects

- Capacity: 80tph

- Project Manager: With tough terrain and high logistics costs, the ALYT80’s steady supply kept us exactly on schedule. Stable output is the real success in this environment.

Move Like Magic: Efficiency That Feels Like Snap-Fit Assembly

- Model: ALYQ90

- Operation Supervisor: Relocation completed within 24 hours — it’s the first time we’ve seen a plant this mobile, without any compromise in mix quality.

Choose the right mobile asphalt plant help you get project done faster

You may have realized that a mobile asphalt plant can help your project get into production faster, save on construction costs, and be more flexible in adapting to future changes. However, with so many mobile asphalt plants on the market, you might be wondering, “Which one should I choose? How can I ensure the asphalt plant is truly suitable for my project, rather than just a fancy spec that doesn’t work well?”

This is exactly what Macroad has in mind. We’ve incorporated years of experience serving global road projects into our equipment design, creating the ALYQ / ALYT /ALB mobile asphalt plants for sale. These offer reliable options tailored to varying project deadlines, budgets, production capacity, and future plans.

ALYQ Mobile Batch Mix Asphalt Mixing Plant

Mobile asphalt batch mixing plant offer precise mixing, easy mobility, and quick installation, ensuring efficient and high-quality asphalt production. Ideal for road construction projects, mobile asphalt batching plant ensure consistent results and reliable performance, making them the best choice for contractors seeking flexibility and efficiency.

- Model: ALYQ40 ALYQ60 ALYQ80 ALYQ100 ALYQ120

- Production capacity: 40-120 tons/hour

- Mixing cycle time:45s

- Asphalt temperature: 120-180 ℃

- Dust filter: Gravity/circulation/bag/water dust filter

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

ALYT Mobile Drum Mixing Plant

The ALYT series of mobile asphalt mixing plant for sale offers flexibility, efficiency, and cost-effectiveness for road construction. Combining mobility and portability, they are ideal for both urban and rural roads. Easy to operate and highly adaptable, this drum mix asphalt plant is a key asset to any road construction project.

- Model: ALYT20 ALYT40 ALYT60 ALYT80 ALYT100 ALYT120

- Production capacity: 20-120 tons/hour

- Dust filter: Bag/water dust filter

- Asphalt temperature: 120-180 ℃

- Cold aggregate feeding capacity: 3.5m³ – 6.5m³

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

ALB Small Asphalt Mixer Machine

The Macroad 10t/h mini mobile asphalt mixing plant is a compact asphalt mixer machine designed specifically for small-scale road repair and maintenance projects. It integrates a high-efficiency mixing system, on-site heating, and a user-friendly interface, producing high-quality hot-mix asphalt in a short time. It is suitable for various maintenance scenarios, including municipal roads, rural roads, and parking lots.

- Output: 10t/h mini mobile asphalt plant meeting the needs of small to medium-sized road maintenance

- Mixing capacity: 1T per batch, mixing time only 10–15 minutes

- Discharge temperature: 3–4 Kg/T

- Compact size: 6 × 2.1 × 2.65 m

- High-efficiency heating: Four-layer hot melt pot design, balancing heat preservation and mixing.

| Item | Configuration | Specification | |

| Generator set | Model | 30kw/ALS-5 | |

| Diesel engine power | 30kw/ Weifang4100D | ||

| Mixer drum | Mixing capacity | T/batch | 1 |

| Mixing time | Min/batch | 10-15min/batch | |

| Output temperature | Kg/T | 3-4 | |

| Mixing drum | M3 | 3.88 | |

| Oil burner | RG5S | ||

| Feeding hopper | M3 | 350kg | |

| Other feature | Asphalt tank | L | 800L |

| Conduct oil tank | L | 200 | |

| Drum material | Double manganese plate | ||

| Rock wool thickness | mm | 50 | |

| Hot melt kettle | 4 layers, each layer is 5cm.

from the inside to the outside it is asphalt oil layer, the conduct oil layer, the fire layer, the rock wool layer |

||

| Total weight | 4.5T | ||

| Outsize (mm) | 6*2.1*2.65 | ||

Why Is Mobile Asphalt Plant So Efficient for Construction?

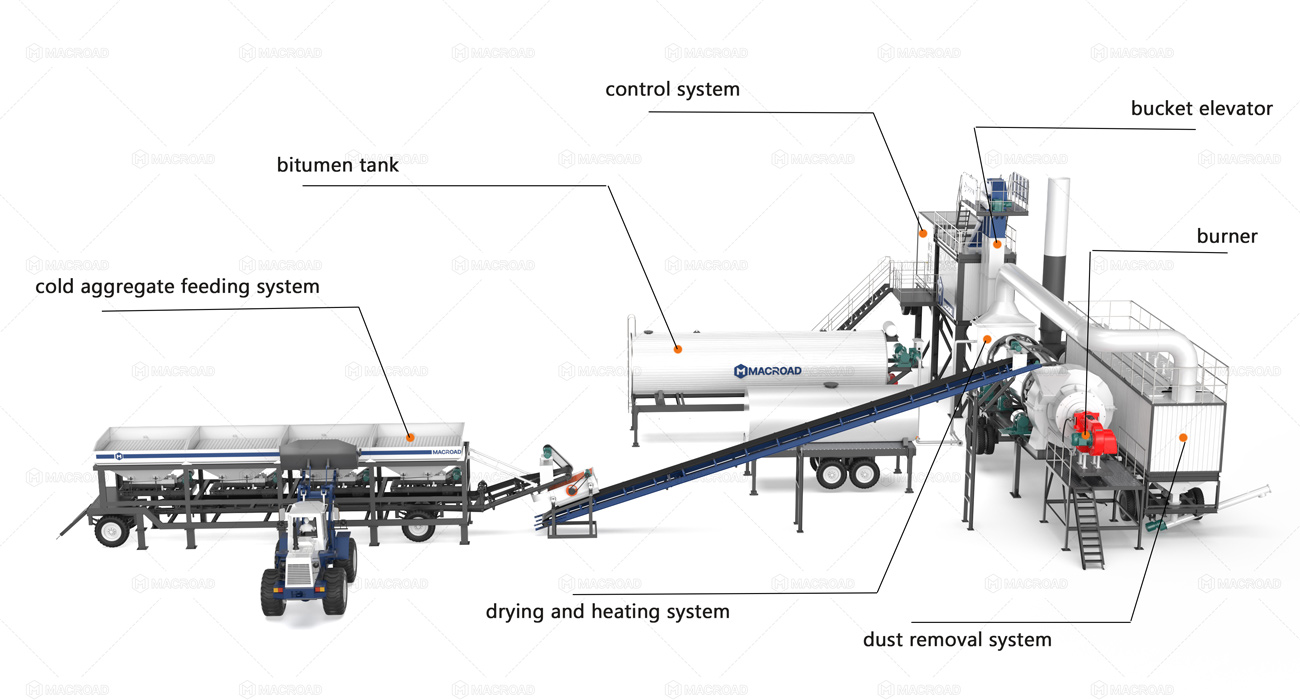

What truly gives Macroad confidence is the unique design of its equipment. Our mobile asphalt mixing plants for sale not only allow for rapid deployment and flexible relocation, but also achieve high-efficiency production, accurate metering, stable operation, and low maintenance costs through their core systems. The following will explore how mobile asphalt plant help construction teams improve efficiency, reduce costs, and ensure successful project completion, focusing on six core systems.

Structure and Transportation Deployment System — Rapid Assembly, Flexible Relocation

- Our Design: Magnetic modular structure, enabling efficient assembly via quick-connect interfaces; quick connection for water, electricity, and gas; no traditional foundation required, can be directly deployed on gravel surfaces or steel platforms.

- What We Can Achieve: Mobile asphalt batch mix plant relocation and commissioning within 24 hours, enabling rapid relocation across multiple construction sites; adaptable to urban, rural, or temporary sites, flexible deployment, improving construction efficiency and saving on civil engineering investment.

Intelligent Control System — Efficient Management, Remote Controllable

- Our Design: AI intelligent bee control operating system integrating electronic inspection, anomaly warning, and maintenance reminders; one-click formula switching, automatic weighing to ensure stable production; supports remote upgrades and mobile APP monitoring.

- What We Can Achieve: Half the number of operators, allowing even beginners to quickly learn; automatic saving of production data, traceability of each batch; remote management makes equipment maintenance smarter and more efficient.

Mixing System — High-Efficiency Tumbling, Durable and Stable

- Our Design: The powerful KingKang boiling system employs dual-shaft forced mixing, ensuring thorough material tumbling; blades and liners require no replacement for 5 years; the machine cover is quick-release for easy cleaning and maintenance.

- What We Achieve: 15% increase in mixing efficiency, 100% production capacity achievement rate, approximately 100 tons more per day than traditional equipment; reduced mobile asphalt plant cost in maintenance, ensuring long-term stable operation.

Screening System — High-Efficiency Screwing, Continuous Production

- Our Design: The patented QuickDraw large-channel vibrating screen features a large screening area; screens can be changed by one person; the motor supports 2000 hours of maintenance-free operation.

- What We Achieve: Doubled screening efficiency, reduced downtime, enabling continuous production; convenient maintenance, easy operation, improving overall construction efficiency.

Metering System — Precise and Economical, Guaranteed Quality

- Our Design: The AI precision metering system incorporates automatic weighing logic and frequency conversion control, with error control ≤1%; the electronic calibration tray offers convenient operation.

- We can achieve: Reduce raw material waste by approximately 80 tons per day, lowering material costs; ensure consistent quality across batches of finished materials, avoiding rework risks and increasing project profitability.

Combustion System — Energy-efficient, Highly Reliable

- Our design: features a dual-fuel system (diesel/natural gas), co-current heating in the drying drum, and a central evaporator to enhance thermal efficiency; an optional dust removal system and automatic fault diagnosis function ensure stable equipment operation.

- We can achieve: Reduce energy costs by approximately 25% and increase heating efficiency by 20%; ensure easy equipment maintenance, real-time monitoring of key components, and precise temperature control, guaranteeing stable and reliable asphalt production for every batch.

Mobile asphalt plant achieve rapid deployment, flexible relocation, high-efficiency production, and stable operation through six core systems. Whether for cross-site construction or temporary emergency projects, they make construction more efficient, costs lower, and projects smoother. Contact us now for a free customized solution and quote to help your project succeed with efficiency.

More Than Mobility: Construction Advantages You Shouldn’t Ignore

The biggest advantage of asphalt plant mobile is their flexibility, but their value goes far beyond that. Even if the project location is fixed, many contractors still prefer mobile asphalt mixing plants because they can solve many problems that fixed mixing plants cannot avoid—from production speed to cost control, to policy approval and asset recovery, each of which directly affects project profits and construction efficiency.

Modular design and low foundation requirements allow mobile type hot mix plant to typically achieve initial production within 5-10 days, saving at least 20 days of preparation time compared to stationary asphalt mixing plants. For projects with tight schedules, this means on-time delivery, avoiding hefty penalties, and allowing construction teams to start production and generate profits sooner.

Stationary asphalt mixing plants require significant upfront investment in foundations, steel structures, cables, etc., which is non-recoverable. Mobile asphalt mixing plants require only simple foundation construction, with almost no demolition losses after project completion. They can be directly relocated or resold, enabling flexible cash flow and reducing investment risk.

Contractors often only receive partial contracts at the beginning of a project, with uncertainty regarding future completion. Demolition and reconstruction of stationary asphalt mixing plants incurs substantial losses, while mobile asphalt mixing plants can be relocated at any time. Even a single relocation saves on secondary construction costs, providing strategic flexibility for the equipment.

Construction approval for stationary asphalt mixing plants is complex, requiring long-term land use and environmental permits, with lengthy approval cycles and high risks. Mobile asphalt mixing plants are temporary equipment, resulting in simplified procedures and faster approval processes, reducing the risk of work stoppages or forced demolitions due to policy changes and ensuring construction continuity.

Mobile asphalt mixing plants can be quickly resold or leased after project completion, generating secondary revenue. Compared to stationary asphalt mixing plants, they offer higher recovery value and more flexible asset utilization, making the equipment not just a construction tool but also a sustainable investment.

Mobile asphalt mixing plants can be deployed on demand and flexibly scheduled according to project timelines and construction pace. Whether for highways, municipal roads, rural roads, or temporary repair projects, they can be quickly put into operation, reducing waiting time and helping construction teams manage resources more efficiently, thus reducing overall project risk.

If you’re still hesitant about choosing a mobile asphalt mixing plant, consider a more comprehensive approach: it not only allows for rapid relocation and flexible deployment, but also shortens the commissioning cycle, reduces civil engineering costs, adapts to project uncertainties, simplifies approval processes, and maintains high asset liquidity. These advantages are unattainable with stationary asphalt mixing plants, but directly improve construction efficiency, reduce risks, and increase return on investment.

Choosing a mobile asphalt mixing plant is not just about selecting equipment; it’s about finding a highly efficient solution that saves time, reduces costs, and enhances flexibility for your project. Take action now and let mobile mixing plants bring a more reliable, efficient, and controllable construction experience to your site.

How to Choose the Right Mobile Asphalt Plant Manufacturers

After understanding the numerous advantages of mobile asphalt mixing plants, your next concern might be: which supplier can truly deliver on these advantages?

Choosing a mobile asphalt plant manufacturer is not just about purchasing equipment; it’s about a comprehensive consideration of construction efficiency, return on investment, and project risk management. A professional asphalt plant supplier will tailor a solution to your specific needs, schedule, terrain conditions, and investment model, ensuring the equipment truly becomes a reliable guarantee for the efficient progress of your project.

Deep Understanding of Mobile Construction Needs

- Construction Adaptability: Suppliers should assess the suitability of mobile asphalt plant based on site area, terrain conditions, road type, and construction complexity to ensure rapid deployment in confined spaces or on uneven ground. Such professional judgment avoids equipment idleness or construction delays due to environmental incompatibility.

- Capacity Matching: Different projects have significantly different output requirements. Suppliers need to recommend appropriate models and capacity configurations based on project schedules and average daily construction volume to ensure that mobile asphalt plant is neither over-configured, increasing costs, nor under-configured, impacting the schedule.

- Schedule Optimization: Experienced suppliers will propose rapid commissioning solutions based on the construction cycle, such as modular layout, hoisting sequence planning, and simultaneous construction suggestions, allowing the equipment to enter a stable production state in the shortest possible time.

Full-Process Support Capabilities

- Installation and Commissioning: Excellent suppliers provide integrated services from equipment transportation to on-site installation, commissioning, and trial production, ensuring that equipment can be put into production as planned and reducing schedule delays caused by improper installation or unfamiliarity with operation.

- Operational Training: Suppliers should provide systematic training to operators, including production operations, troubleshooting, and safety management, enabling the team to quickly master equipment operation and ensuring stable production even for novices.

- After-Sales Maintenance: Reputable suppliers provide remote monitoring, regular inspections, timely spare parts supply, and a rapid response mechanism to ensure long-term stable equipment operation and reduce downtime and production loss risks.

Strategies for Different Investment Models

- EPC Model: Suppliers should provide one-stop solutions, including equipment selection, installation, commissioning, and process optimization, reducing the project owner’s management burden and allowing contractors to focus on construction rather than equipment management.

- PPP/PPT Model: Suppliers need to provide complete lifecycle cost analysis, feasibility studies, and flexible financing, leasing, or cooperation options to adapt to long-term operation and return cycles while reducing project funding pressure.

- Self-Investment Model: Suppliers must ensure high equipment availability and remote management capabilities, allowing investors to achieve stable returns during project operation while reducing human intervention and management costs.

Technical Reliability and Quality Assurance

- Core Component Durability: Key components such as the mixing shaft, blades, and liners must withstand long-term high-load operation. Suppliers should provide relevant lifespan guarantees to ensure long-term stable production.

- Intelligent Control System: Excellent suppliers equip their equipment with accurate metering, automatic reloading, and remote monitoring systems to ensure stable and traceable finished product quality, avoiding losses caused by rework or quality issues.

- Ease of Maintenance: The mobile asphalt plant design should facilitate quick and easy disassembly and maintenance, reducing downtime and manual operation difficulty, and improving construction efficiency.

Case Study Experience and Customer Reputation

- Project Diversity: Suppliers should have experience covering different types of projects, including highways, municipal roads, rural roads, and emergency repairs, and be able to provide feasible solutions for customers with different needs.

- Cross-Regional Experience: Mobile mixing plants are often used for cross-regional construction. Suppliers need to have successful case studies under different terrains, climates, and construction conditions to ensure stable operation of the equipment in complex environments.

- Customer Reputation: Real-world case studies and customer reviews are strong evidence of a supplier’s capabilities and can help potential customers assess equipment performance, construction efficiency, and service reliability.

After-sales service and long-term cooperation capabilities

- Rapid response: The mobile asphalt plant manufacturer should provide timely technical support and troubleshooting to ensure that problems during equipment operation can be resolved as soon as possible, minimizing project interruptions.

- Spare parts guarantee: Ensure a long-term supply and sufficient inventory of core components to avoid production stoppages due to spare parts shortages.

- Continuous optimization: The supplier continuously upgrades the control system and process solutions to improve the long-term operating efficiency of the equipment and maximize return on investment.

Choosing a mobile asphalt plant manufacturer is a crucial step in determining project efficiency, cost, and risk. Macroad supplier mobile asphalt plant china meets all these requirements: from a deep understanding of construction needs and full-process support to providing strategies for different investment methods, to offering highly reliable technical equipment, extensive case experience, and a comprehensive after-sales system, ensuring your project progresses efficiently and smoothly. Choosing Macroad means choosing a partner who truly considers your construction and investment, maximizing the advantages of mobile asphalt mixing plants.

FAQs

Are mobile asphalt mixing plants more expensive than stationary asphalt mixing plants?

How to maximize the production capacity of a mobile asphalt plant?

How long does it take to relocate a mobile asphalt mixing plant?

How environmentally friendly are mobile asphalt plants?

Is daily maintenance of asphalt plant mobile difficult?

Can mobile asphalt plant adapt to extreme climates?

Are mobile asphalt mixing plants suitable for long-term use or short-term projects?

Choosing a mobile asphalt plant is not just choosing a piece of equipment, but rather selecting an efficient, flexible, and controllable construction solution. Whether it’s shortening the commissioning cycle, reducing civil engineering costs, ensuring project quality, or improving asset liquidity, mobile asphalt plant can bring significant advantages to your project.

Macroad is committed to providing clients with end-to-end support, from equipment selection, rapid deployment, and intelligent control to post-construction operation and maintenance, ensuring your construction is efficient and reliable, and maximizing your return on investment. Contact us today to let our professional team tailor the most suitable mobile asphalt mixing plant solution for your project, making every construction operation efficient, safe, and controllable.