In the production process of asphalt mixing plants, the formulation and proportion of each raw material directly determine the performance stability, construction adaptability, and project quality consistency of the finished mixture. Whether it’s aggregate gradation, mineral powder ratio, or asphalt dosage and temperature control, any slight deviation can affect the final road quality under the amplification effect of engineering projects.

With the expansion of project scale, the diversification of raw material sources, and the continuous improvement of quality standards, traditional formulation optimization methods, which mainly rely on static formulations and manual experience adjustments, are gradually revealing their limited response speed and insufficient stability. Against this backdrop, the industry has begun to focus on AI formulation optimization, hoping to achieve a higher level of formulation stability and production consistency through data-driven and systematic control.

Guide to AI Formula Optimization in Asphalt Plants

In the operation of an asphalt mixing plant, AI-based formula optimization is not simply about generating new formula parameters using algorithms, nor is it a direct replacement of the current formula. Its core objective is to identify, assess, and make limited corrections to key deviations that may occur during production, within the framework of a predetermined design formula and engineering specifications. This reduces the impact of raw material fluctuations and equipment execution errors on the quality of the finished product.

AI formula optimization typically involves the following collaborative levels:

| Raw material level: | Fluctuations in aggregate gradation, moisture content, mineral powder characteristics, and asphalt properties during actual production |

| Equipment execution level: | Weighing accuracy, feeding sequence, mixing status, and the stability of heating and temperature control |

| Production process level: | Batch repeatability, identification of abnormal operating conditions, and recording of manual intervention |

| Feedback and correction level: | Judging deviations and proposing correction suggestions based on historical and real-time data |

In this system, AI’s role is closer to that of an auxiliary decision-making and dynamic correction tool than a fully automated real-time formula reconstruction system. Its effectiveness depends not only on the algorithm’s capabilities but also on the direct constraints of engineering conditions, equipment accuracy, and control logic.

Therefore, the essence of AI formula optimization is to stably execute a given formula within the limits allowed by engineering, and make limited adjustments when necessary, rather than freely changing the formula ratio in production.

From Conventional to Smart: Rethinking Mix Management in Asphalt Plants

In asphalt mixing plants, maintaining stable formulations is crucial not only for finished product quality but also directly impacts construction efficiency and material consumption. AI-powered formulation optimization, through data analysis and systematic monitoring, can identify deviations within a defined formulation framework and propose corrective measures, providing a more reliable means of asphalt production execution.

Compared to traditional methods relying on manual experience and static formulation management, this approach offers potential advantages in addressing raw material fluctuations and equipment differences.

| AI Formulation Optimization | Model | Traditional Methods |

| Real-time data analysis can quickly identify trends in raw material characteristics and propose correction strategies or suggestions, making batch-to-batch deviations easier to control. | Response to Raw Material Fluctuations | Rely on manual observation and batch adjustments, resulting in limited response speed. Operators must rely on experience to make judgments, often leading to delayed or over-correction. |

| Continuous monitoring of key parameters and comparison with historical data can reduce batch-to-batch differences and improve the performance consistency of finished mixtures. | Batch Repeatability and Production Consistency | Static formulations are easily affected by weighing errors, mixing efficiency, and changes in environmental conditions across different batches, leading to fluctuations in mixture performance. |

| Through algorithmic analysis of real-time data, potential anomalies can be identified early, providing adjustment suggestions and reducing losses caused by delayed detection. | Identification of Abnormal Conditions | Abnormal situations often rely on operator experience for discovery, resulting in delays, and deviation correction often requires manual intervention. |

| Systematic data management and analysis can provide quantitative data for engineering management, supporting the optimization of raw material procurement, equipment maintenance, and production plans. | Data Support for Engineering Decisions | Primarily rely on fragmented data and manual recording, making global analysis and long-term optimization difficult. |

On-Site Constraints: Practical Limits for AI Formulation Optimization

In laboratory settings or ideal models, AI-based formulation optimization typically relies on stable inputs and controllable variables. However, in real-world asphalt mixing plant projects, production conditions often do not meet these fundamental assumptions. Many problems that seem solvable by algorithms become structural constraints under constantly changing conditions of raw materials, construction environment, and production organization on-site.

Local Raw Material Fluctuations: AI Struggles to Establish a Stable Input Basis

Raw materials are the fundamental input for AI formulation optimization, but in actual engineering projects, their state is often difficult to maintain stability. The physical properties of aggregates and asphalt fluctuate continuously with changes in material source, storage method, and environment. This uncertainty directly weakens the AI’s reliance on the continuity and repeatability of input variables.

- Unstable Input Variables: Aggregates are usually stored in the open, and their moisture content is significantly affected by weather and sourcing location. Even within the same silo, it is difficult to maintain a stable state, making it difficult for AI to establish a reliable moisture content input model.

- Lagging Data Acquisition: Moisture content is mostly obtained through intermittent sampling or empirical estimation, failing to reflect the actual state in real time for each batch, causing deviations in AI calculation results during execution.

- Difficulty in Fully Parameterizing Raw Material Differences: Differences in particle size distribution and surface characteristics among different material sources are difficult to fully express with limited parameters, limiting the AI’s responsiveness to changes in raw materials.

Local Construction Environment Differences: AI Struggles to Cope with Non-Standard Working Conditions

The construction environment directly affects the actual performance of the mixture, but these conditions vary significantly between different projects. Factors such as climate, construction pace, and transportation distance make it difficult to uniformly describe the formulation execution process, thus weakening the AI’s adaptability to changing working conditions.

- Highly non-standardized working conditions: Temperature, humidity, and construction time windows vary significantly across different projects, causing the actual effects of the same formulation to deviate under different environments.

- Difficulty in fully quantifying environmental variables: Some environmental factors cannot be collected and input into the system in real time, leading to AI making judgments based on incomplete information.

- Project priorities constrain algorithm execution: In actual construction, continuous output and schedule assurance usually take precedence over formulation fine-tuning, limiting the execution space of AI optimization suggestions.

Project schedule and production requirements: Compressed AI adjustment space

In most engineering projects, production stability and construction schedule are primary goals. Any formulation adjustment must be made without affecting production and continuous construction, limiting the effectiveness of AI formulation optimization in reality to a very small extent.

- Extremely limited adjustment window: Continuous production requires minimizing interruptions, strictly limiting the frequency and magnitude of formulation adjustments.

- Compressed trial-and-error space: Any experimental adjustments may affect paving quality and acceptance results, and the field has a low tolerance for algorithm adjustments.

- Production targets take precedence over optimization targets: Under high-load production conditions, maintaining stable output is often more valuable than minor optimizations.

Simultaneous changes in multiple variables: Field conditions exceed the capabilities of a single model

In real production processes, multiple factors often change simultaneously, making it difficult to attribute formula deviations to a single variable. In such cases, AI models struggle to accurately determine causal relationships, and their optimization decisions are unlikely to be directly adopted by the field.

- Variable coupling leads to attribution difficulties: Simultaneous changes in raw materials, equipment status, and environmental conditions make it difficult to trace formula problems back to a single cause.

- Deviation between model assumptions and reality: A single model cannot cover complex combinations of working conditions, limiting the predictive accuracy of AI.

- Engineering risks drive conservative decision-making: To avoid quality risks, the field often reduces the decision weight of the algorithm, making AI more of an auxiliary tool for judgment rather than a primary driver of optimization.

From the perspective of on-site production conditions, AI-based formula optimization is primarily constrained by real-world limitations such as unstable inputs, varying operating conditions, and limited execution space. Under these conditions, algorithmic capabilities are not the sole determining factor; the execution capabilities of equipment and control systems become the next key constraint.

Equipment and Control Systems: Inherent Limitations for AI Optimization

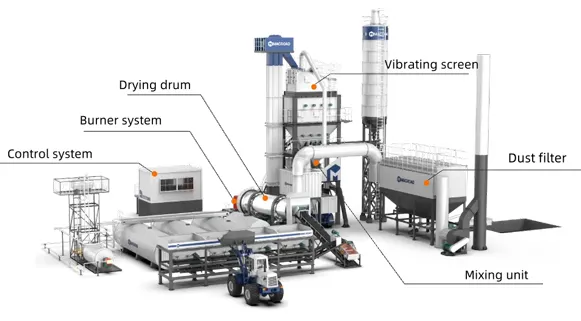

When discussing the engineering feasibility of AI-driven formulation optimization, the equipment itself is often viewed as a neutral executor. However, in practical applications, the equipment structure and control system of hot asphalt mixing plant are not designed for continuous, proactive formulation exploration; their core objective is stable, repeatable, and traceable production. This design logic largely determines the boundaries of AI’s role in formulation optimization.

Control systems are centered on deterministic execution

Most mainstream asphalt mixing plants currently employ PLC-based industrial control systems, designed to strictly execute predetermined process parameters rather than continuously adjust strategies during production. This deterministic control logic inherently differs from the dynamic optimization emphasized by AI.

- Execution takes precedence over decision-making: Control systems prioritize accurate command execution and consistent results, lacking design support for frequent, continuous small-scale parameter changes. This often leads to simplification or limitation of AI outputs at the control layer.

- Parameter modification has process hurdles: Most critical formula parameters require authorization or process switching to take effect, limiting AI’s ability to adjust in real-time during continuous production.

Equipment responsiveness has physical and mechanical boundaries

Changes in formula parameters do not guarantee immediate and accurate equipment execution. Weighing systems, conveying mechanisms, and actuators all have response time and accuracy boundaries. These physical constraints amplify the discrepancy between AI optimization results and actual production.

- Execution has time lag: A significant delay exists between parameter adjustment and the actual entry of materials into the mixing system, making it difficult for AI’s real-time calculations to be synchronously reflected in the current batch.

- Mechanical precision determines the lower limit: Even if AI provides more refined adjustment suggestions, the weighing accuracy and execution resolution of the equipment may not be able to fully realize these changes.

Limited controllable parameters, discretized optimization

At the equipment level, not all variables affecting formula performance can be continuously controlled. Most key parameters are set discretely, inevitably compressing the AI output during implementation.

- Adjustment granularity limited by equipment structure: Parameters such as valve opening and weighing step size have minimum adjustment units, limiting the scope for fine-grained AI optimization.

- Continuous optimization transformed into phased adjustments: The continuous calculation results of AI are broken down into a small number of controllable nodes at the execution layer, weakening its theoretical advantages.

Safety and quality responsibility take precedence over optimization goals

Asphalt mixing plants are high-energy-consuming and high-load equipment; their control systems are designed with operational safety and quality stability in mind. In this context, it is difficult for AI to directly intervene in the core decision-making level.

- Safety interlocks limit algorithm permissions: Multiple safety protection mechanisms prevent AI from bypassing manual or system confirmation to directly adjust key parameters.

- Quality responsibility-driven conservative strategy: Under the premise that quality risks require traceability of responsibility, on-site personnel tend to use AI as an auxiliary decision-making tool rather than an automatic control subject.

From the perspective of equipment and control systems, AI-based formulation optimization is not a simple algorithmic problem, but rather is subject to multiple constraints, including control logic, mechanical boundaries, and safety responsibilities. Within this system architecture, the role of AI is often limited to providing suggestions and assistance.

Testing and Failure Costs: Challenges in Validating AI Optimization

In a road construction project, asphalt mixing plants typically operate in continuous production. The daily production plan is fixed, and transport vehicles and paving equipment operate in a synchronized manner. If, at this point, the system requests verification of the optimization effect using new formula parameters, the project manager faces a real choice: continue with the already validated stable formula, or, within the established timeframe and quality responsibilities, conduct actual testing of the not-yet-fully-validated adjustment scheme.

It is in this decision-making scenario that AI formula optimization faces not a problem of computing power, but rather a problem of the cost of failure. The following questions will help you better understand the verification dilemma of AI formula optimization.

What are the direct consequences if AI-manipulated formulation adjustments fail to meet expectations?

The impact is often not localized, but rather amplified across batches.Under continuous production conditions, formulation adjustments affect multiple batches of the mixture. Once performance deviates from requirements, materials already produced and transported are typically irrecoverable, directly resulting in losses in material, transportation, and labor costs.

Why can’t such adjustments be considered low-risk tests?

Because the verification of formulation performance has a significant lag.The actual performance of the mixture usually only becomes apparent after asphalt paving, compaction, or even initial use. By the time problems are exposed, production has already continued, making it difficult to reverse the adjustments in a timely manner.

Can verification be achieved through controlled, small-scale parameter adjustments?

On-site, even small-scale adjustments can trigger systemic impacts.The combined effects of equipment response delays, raw material fluctuations, and environmental conditions can amplify adjustments that were initially considered controllable, causing results beyond expectations.

Why is there a general caution regarding experimental adjustments in practical engineering?

Because the cost of failure is severely disproportionate to the potential benefits.Even if AI optimization is successful, the benefits are usually gradual and limited. Failure, however, can impact project schedules, quality acceptance, and contract fulfillment, making the risks far outweigh the rewards.

Can it be fully validated in non-critical projects before widespread adoption?

This is theoretically feasible, but practically difficult to implement.Engineering projects have significantly different operating conditions; even if effective in one project, it’s difficult to directly replicate in others.

Can simulation or offline testing replace on-site validation?

Simulation can reduce risk, but it cannot fully cover real-world conditions.The randomness of raw material fluctuations, equipment status, and operating methods makes it difficult for offline testing to reproduce the complexity of on-site conditions.

Can validation risks be gradually reduced through long-term data accumulation?

Data accumulation is valuable, but it cannot eliminate phased risks.Until the data fully covers extreme operating conditions, AI cannot guarantee stable operation under all conditions.

When formula optimization validation can only be completed in actual production, and the costs of failure are highly concentrated and difficult to recover, engineers will exercise extreme caution towards any experimental adjustments. In this risk structure, AI’s more realistic role is to provide analytical support rather than to drive decision-making.

Human Involvement in AI Formula Optimization

In actual production, AI-driven formula optimization is not an independent technical module, but rather embedded in a human-centric operational system. Regardless of how much the algorithm’s capabilities improve, its application boundaries are ultimately determined by the responsibilities, experience, and organizational processes of on-site personnel. Understanding these real-world factors is key to determining whether AI can be adopted in the long term.

Responsibility Cannot Be Transferred: AI’s Decision-Making Boundaries Must Be Defined by Humans

At an asphalt mixing plant, any formula adjustment directly impacts quality, schedule, and contract fulfillment, and these consequences must be borne by a clearly defined responsible party.

From an operational perspective, responsibility constraints are primarily reflected in three aspects:

- Quality Responsibility: Formula deviations may lead to substandard mixture performance, directly affecting acceptance results.

- Schedule Responsibility: Failed adjustments may cause downtime, rework, or construction delays.

- Contractual Responsibility: Project outcomes are tied to contract terms; risks cannot be transferred to the system.

Because responsibility cannot be borne by algorithms, AI’s more realistic role on-site is to provide a basis for judgment, rather than directly replacing human decision-making.

Operational Experience Is Not an Obstacle, but a Risk Filtering Mechanism

Under complex and uncertain production conditions, the core value of on-site experience lies not in pursuing theoretical optimality, but in reducing the probability of error.

Experience-based judgment typically focuses on the following questions:

- Is the current deviation still within an acceptable range?

- Is continuing production safer than making adjustments?

- Has this problem occurred under similar conditions before?

This judgment logic does not exclude data, but rather prioritizes validated paths in high-risk environments. When AI’s suggestions conflict with experienced judgments, the more controllable risk solution is often prioritized on-site.

Technology acceptance depends on trust, not algorithmic complexity

At the operational level, whether to adopt AI’s suggestions is primarily a matter of trust, not a technical one.

When deciding whether to execute AI suggestions, operators typically focus on:

- What understandable basis is the suggestion based on?

- Whether the adjustment range is within a safe range?

- Whether deviations can be detected and corrected in a timely manner.

- When the AI’s decision-making logic is not clearly understood, its suggestions are often considered potential sources of risk and are treated with caution.

Organizational processes determine how far AI can go

AI’s position in the system is not entirely determined by technical capabilities, but rather by organizational processes and authority structures.

In the actual processes of most asphalt mixing plants:

- Key parameter adjustments require manual confirmation.

- Manual intervention is prioritized in abnormal situations.

- System automation prioritizes stable operation.

Under such process design, AI is more suitable for placement at the monitoring and suggestion layer, rather than directly entering the automatic control layer. This arrangement does not limit technological development, but rather represents the engineering system’s proactive risk management.

From an operational perspective, the promotion of AI-driven formulation optimization is not a matter of conflict between humans and technology, but rather a question of how to rationally embed technology into existing responsibility structures, experience systems, and organizational processes. Human judgment is not an obstacle to AI, but rather a fundamental basis upon which it must rely in engineering practice.

Practical Approaches to AI Formulation Optimization

The limitations faced by AI in formulation optimization in engineering practice are not due to insufficient algorithmic capabilities, but rather determined by factors such as production risk structure, system stability requirements, and liability boundaries. Therefore, its development must proceed within controllable, explainable, and verifiable engineering frameworks, rather than pursuing merely superficial automation. Based on this practical constraint, the application of AI in formulation optimization is more likely to evolve along the following path.

From Formula-Driven to Decision Support

In real-world production, formula adjustments directly impact finished product quality and engineering risks. Completely relinquishing control to algorithms makes it difficult to define responsibility and recover risks. Therefore, on-site engineers tend to retain human decision-making power.

Feasible Applications:

- Formula Deviation Risk Alert: AI compares real-time and historical data to identify potential quality deviations in advance, providing early warnings to operators.

- Multi-Solution Result Comparison Analysis: Simulates the possible outcomes of different formula strategies, allowing human decision-makers to choose the optimal solution.

- Optimization Suggestion Scoring and Prioritization: Based on historical validation results, provides operators with priority references for solutions, helping to make decisions faster and safer.

From Real-Time Adjustment to Key Node Intervention

Continuous, real-time formula optimization requires highly stable input conditions, but the volatility of on-site operating conditions makes this premise difficult to meet in the long term. In contrast, intervention at key nodes makes risk control easier.

Feasible Applications:

- Pre-Formula Switching Assessment: Before changing raw material batches or construction standards, AI analyzes the compatibility and potential risks of the new formula.

- Abnormal Condition Trigger Analysis: When key parameters exceed normal ranges, AI intervenes with analysis, rather than continuous intervention.

- Key Indicator Monitoring During Construction Phase: During critical processes such as paving and compaction, AI provides assisted judgment to support human decision-making.

From Production Validation to Offline Validation and Experience Accumulation

The failure cost of formula optimization is highly concentrated; a single incorrect adjustment can lead to irreversible quality or schedule losses. Therefore, validation should prioritize offline analysis and experience accumulation.

Feasible Application Directions:

- Historical Data Backtracking Analysis: Analyzing the effectiveness of formula strategies through data from completed projects reduces the risks of on-site experiments.

- Structured Experience Organization: Transforming operator experience into model parameters and rules to support future decision-making.

- Offline Simulation Validation: Testing AI optimization strategies in a simulated environment to ensure controllable results before recommending them to on-site operations.

From Single-Model Decision-Making to Combined Applications Under Engineering Constraints

The production process of asphalt mixing plants involves numerous unquantifiable factors. A single model cannot cover all engineering constraints, necessitating the combination of rules and experience to form controllable strategies.

Feasible application directions:

- Rule-Model Collaboration: AI optimization results are only effective within the limits allowed by safety boundaries and operational rules.

- Hierarchical Decision-Making Structure: Separating judgment, suggestion, and execution to avoid AI directly assuming engineering responsibility.

- Condition-Triggered Optimization: AI provides adjustment solutions when specific conditions are triggered, rather than continuously and proactively controlling the entire production process.

A feasible approach to AI-driven formulation optimization in engineering practice focuses on a combination of decision support, intervention at key points, offline verification, and engineering constraints, rather than pursuing full-process automation. This approach allows AI to gradually realize its value while mitigating risks and laying the foundation for future levels of automation.

In summary, the greatest value of AI-driven formulation optimization in asphalt mixing plants at the current stage lies not in replacing manual formulation control, but in enhancing cognitive capabilities and reducing decision-making uncertainty.

The complexity of engineering sites, the structural limitations of equipment systems, the asymmetry of failure costs, and the reality of non-transferable responsibility all dictate that AI must operate within a human decision-making framework. This is not an obstacle to technological development, but rather a rational response of the engineering system to risk.

Truly sustainable AI-driven formulation optimization should start from engineering realities, adhering to the principles of verifiability, explainability, and controllability, and gradually integrate into the existing production system. Only along this path can AI move from concept to long-term, stable engineering applications.