More than 20 years of strength

Full-cycle worry-free service

In road construction, consistent asphalt mixture quality means durable pavement and reduced repairs. High production efficiency means projects can be delivered on schedule or even ahead of schedule, saving significant time and costs. Intelligent operating systems allow construction teams to easily manage the entire process, reducing reliance on manual experience. Comprehensive after-sales and spare parts support ensures long-term, stable operation of the equipment, eliminating downtime caused by minor issues.

These seemingly disparate values actually all point to a common core: finding reliable asphalt plant suppliers. Choosing the right asphalt plant manufacturers is like building a solid foundation for the entire project.

The Real Demand Person of Asphalt Mixing Plant

As we discussed earlier, the value of equipment lies in quality, efficiency, intelligence, and service. These aren’t abstract terms; they’re real-world challenges faced daily on the construction front lines. Different roles—general contractors, municipal companies, airport runway contractors, and even local maintenance teams—have distinct responsibilities and goals, and their requirements for asphalt mixing plants are also quite different.

| Transportation Infrastructure General Contractors (EPC): | Undertake turnkey projects for large-scale transportation infrastructure projects, such as national and provincial highways, transportation hubs, and cross-river bridges. They are the coordinators and responsible for the entire project, ensuring on-time delivery and quality standards. |

| Municipal and Urban Construction Units: | Responsible for the reconstruction of urban arterial roads, interchanges, and overlays on existing roads. They often face construction constraints in the urban traffic environment. Their tight project schedules often require phased construction to minimize the impact on urban traffic. |

| Airport and Heavy-Duty Engineering Contractors: | Specialize in high-grade roads and heavy-duty traffic scenarios, such as airport roads and port yards. They place extremely high demands on asphalt mix performance, as these pavements must be rutting-resistant and have stable, high-load bearing capacity. |

| Regional Mixing Plants and Long-Term Operators (PPP/BOT): | Responsible for long-term regional material supply or commercial mixing, or operate road projects under PPP or BOT models. They prioritize equipment cost-effectiveness and stability to ensure long-term return on investment and continuous supply. |

| Local Maintenance and Emergency Teams: | Local highway bureaus, maintenance stations, and emergency repair teams primarily focus on rural roads or emergency repairs. They often require rapid equipment startup and shutdown, and the completion of small, multiple batches of work to ensure road safety and smooth traffic. |

As can be seen, the demand for asphalt mixing plants ranges widely, from large-scale, high-speed construction to small-scale emergency maintenance. Different roles determine different project types, which in turn shape different equipment requirements. Understanding these differences is the first step in selecting the right equipment and evaluating asphalt batch mix plant suppliers capabilities.

One Asphalt Plant Supplier, Multiple Solutions——Macroad Product Matrix

Different projects place varying demands on asphalt mixing plants, with some requiring high production capacity, others seeking flexible relocation, and others prioritizing long-term economic efficiency. Macroad has consistently developed a variety of asphalt mixing plants based on real-world construction scenarios and customer needs. These plants cover large-scale projects like highways, bridges, and airports, while also meeting the flexible needs of municipal services, maintenance, and emergency response.

ALQ Series

The ALQ Series batch mix asphalt plant is renowned for their stable structure and wide production capacity range. They feature high-precision batching and intelligent control functions, ensuring continuous and stable production quality. It is particularly suitable for large-scale infrastructure projects such as highways, cross-river bridges, and tunnel connectors, meeting the needs of transportation infrastructure general contractors and heavy-duty engineering contractors for large-scale production capacity, quality control, and strict construction schedules.

- Models: ALQ40 ALQ60 ALQ80 ALQ100 ALQ120 ALQ160 ALQ320

- Production Capacity: 40-400 t/h

- Mixing Cycle: 45s

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

ALYQ Series

The ALYQ series mobile asphalt batching plant features a modular, quick-assembly design for easy transportation and flexible installation, supporting frequent construction site relocations and enabling relocation in as little as 24 hours. This equipment combines the high-quality mixing performance of a high-pressure asphalt mixing plant with the flexibility and convenience of a mobile asphalt mixing plant. For municipalities and urban construction agencies, the ALYQ series is an ideal choice for urban arterial road reconstruction, interchanges, and other municipal road construction projects—minimizing traffic disruption while efficiently ensuring project quality and deadlines.

- Model: ALYQ40 ALYQ60 ALYQ80 ALYQ100 ALYQ120

- Production capacity: 40-120 t/h

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

- Asphalt temperature: 120-180 ℃

- Mixing Cycle: 45s

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

ALT Series

The ALT series of drum type stationary asphalt mix plants specialize in continuous production, offering simple processes, low energy consumption, excellent economic efficiency, and long-term operational stability. They are often used in regional asphalt plants or commercial, long-term supply projects, particularly under PPP/BOT models, helping customers maximize their return on investment.

- Model: ALT20 ALT40 ALT60 ALT80 ALT100

- Production capacity: 20-100 t/h

- Dust filter: Bag/Water dust filter

- Asphalt temperature:120-180 ℃

- Finished Asphalt Storage Bin: 3-9 tons

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

ALYT Series

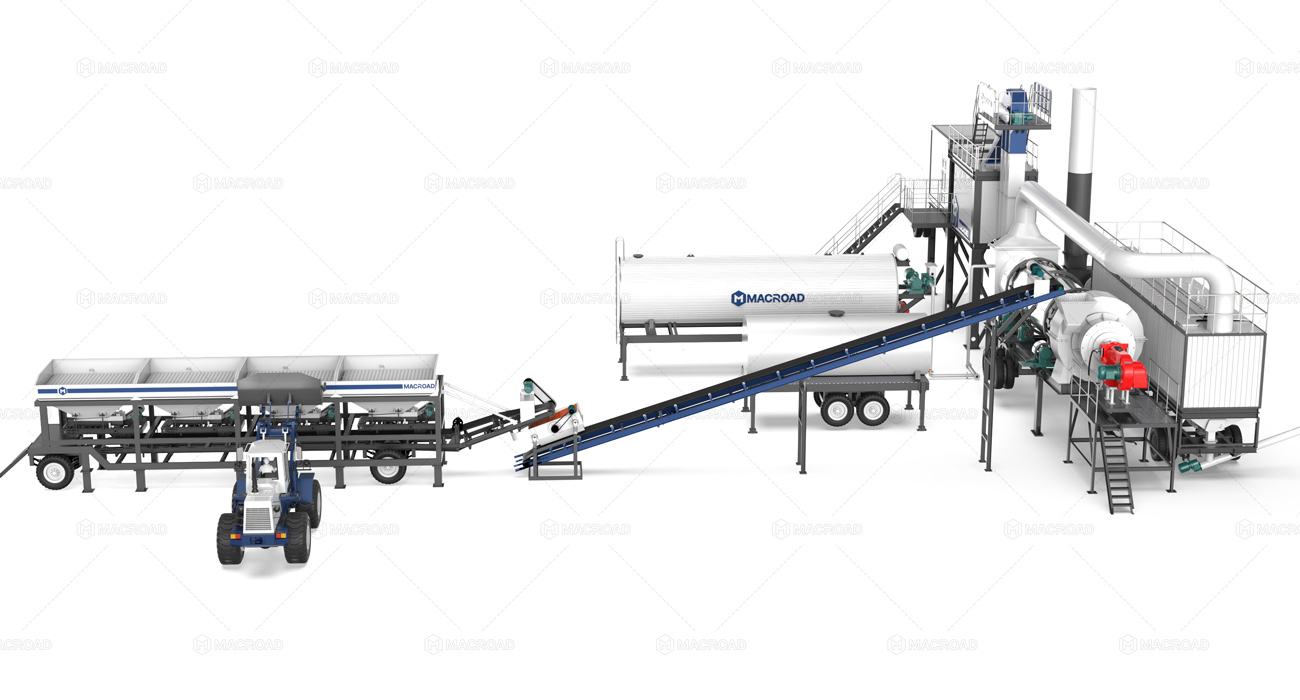

The ALYT series mobile asphalt drum mix plant features a low-profile, tower-less design, flexible start-up and shutdown, a compact footprint, and can be deployed and dismantled quickly. It is ideal for rural road maintenance, small-batch repairs, and emergency repairs, providing an efficient and cost-effective solution for local road management departments and maintenance teams.

- Model: ALYT20 ALYT40 ALYT60 ALYT80 ALYT100 ALYT120

- Production capacity: 20-120 t/h

- Dust filter: Bag/Water dust filter

- Asphalt temperature: 120-180 ℃

- Cold Aggregate Feeding Capacity: 3.5m³ – 6.5m³

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

Leave the complexity to us and leave the efficiency to you

Choosing asphalt equipment manufacturers is never an easy decision. A truly reliable asphalt mixing plant manufacturers not only provides high-performance equipment but also provides comprehensive support throughout the entire process, from selection and installation to commissioning and operation and maintenance, ensuring the smooth progress of your project. Macroad understands this, and therefore, at every stage of R&D and manufacturing, we focus not only on the equipment itself but also on its performance and long-term stability at your project site.

Our goal is clear: to ensure our customers achieve the most reliable and efficient output with the most reasonable investment. To this end, the Macroad technical team divides the entire asphalt mixing plant into several key components and conducts in-depth optimization of each. These improvements are the result of valuable experience accumulated through our long-term collaboration with global customers.

Feeding and Screening

- Increased Capacity and Anti-Blocking: The cold aggregate silo has a 20% increased capacity, with a larger hopper angle and anti-bridging lining. A variable frequency belt and gate linkage prevents instantaneous feed interruptions and overflows.

- Efficient Screening: Large-channel vibrating screens (QuickDraw/Proslide) feature a larger screen area and quick module removal. The fully enclosed screen body is equipped with a parallel negative pressure exhaust system to prevent dust escape.

- Material Arrival Visualization: Material level sensors and abnormality warnings provide alarms for silo shortages and jams. Inspection doors and safety platforms are located at key locations, allowing single-person screen replacement.

Drying and Heating

- Improved Thermal Efficiency: Downstream heating + central air guide structure, equipped with high-efficiency lift plates and drum insulation, improves heat utilization by approximately 25–30% compared to traditional solutions.

- Fuel Flexibility: The burner supports oil, gas, and coal options with fast switching. Combined with combustion control and automatic damper ratio matching, it achieves a wider stable fire zone and more stable heat load.

- Temperature Control: Dual infrared and contact temperature monitoring controls temperature fluctuations to ±0.5°C. Drying exhaust heat is recovered for aggregate and fuel preheating.

Weighing and Mixing

- High-precision weighing chain: Aggregate weighing ±0.5%, powder and asphalt ±0.25%; AI automatic weighing + spiral frequency conversion precise feeding, supporting electronic calibration.

- Intelligent formulation: One-touch recipe switching, secondary metering/secondary feeding, and dynamic secondary weighing strategies, with full data traceability.

- Efficient and wear-resistant mixing: Vigorous powerful kingang boiling mixing promotes sufficient relative movement of aggregates.

Dust Removal and Environmental Protection

- Dual-stage dust removal: A cyclone + bag filter combination delivers 99.9% dust removal efficiency and ≤30mg/m³ emissions, meeting EU standards.

- Closed-loop dust recycling: 95% of fine powder is recycled back into the powder silo and added to the mix in proportion, reducing the need for purchased fillers.

- Installation-friendly: The retractable dust collection duct allows for a ±3cm installation tolerance; the fully sealed sieve and negative pressure exhaust suppress dust at the source.

Control and Intelligence

- Integrated control: One-touch start and stop streamlines 50 operations to one; three modes (computer/touch screen/button) cater to different needs.

- Automated production: The entire process from aggregate batching to mixing to unloading is automated; recipes can be switched with one click, permissions can be managed, and operation records are traceable.

- IoT: Real-time monitoring of operating status, automatic maintenance reminders, remote diagnosis/upgrades; production, energy consumption, and alarm logs can be viewed via a mobile app.

- Data assets: Production data is permanently stored online, supporting report export and quality tracking.

Reliability and Operation and Maintenance

- Modular/Quick Connection: Magnetic modular structure with quick-connect connections for water, electricity, and gas, enabling rapid 24-hour turnaround and production. A simple mobile equipment foundation design is available, reducing construction time and costs.

- More Reliable Drive: The hot aggregate hoist utilizes double-row chains with fully enclosed protection, reducing chain breakage by approximately 60%. Direct drive replaces chain drive in some systems, reducing bearing wear by approximately 60%.

- Predictive Maintenance: Online monitoring of over 20 parameters, including motor temperature, belt tension, vibration, and temperature, with predictive alarms. Standardized spare parts and an on-site emergency spare parts kit are available.

These optimizations aren’t simply a stacking of configurations; they’re centered around your overall goals: more consistent quality, faster schedules, lower overall costs, and greater safety in the whole process of asphalt production. Macroad breaks down complex engineering problems into individual components, then aggregates improvements in each into quantifiable benefits, ultimately delivering a suite of equipment and services that can withstand field scrutiny.

If you’d like, please share your project location, target production capacity, site transfer frequency, and fuel availability. Based on these optimization strategies, we as asphalt mixing plant supplier, will generate a more tailored configuration recommendation and cost-effective calculations.

How to Choose Reliable Asphalt Plant Supplier

A good supplier not only provides high-quality concrete mixing plant equipment but also offers technical support, after-sales service, and spare parts guarantee to safeguard your project. Next, we will teach you how to comprehensively evaluate and select the most suitable asphalt mixing plant supplier based on multiple dimensions, including company qualifications, technical level, after-sales service, and price/performance ratio, to ensure that every investment is worthwhile.

Investigate the asphalt plant supplier’s qualifications and strength

Enterprise qualifications and strength are the basic guarantee for selecting asphalt mixing plant supplier, reflecting their compliance and operational stability.

- Qualification Review: Verify suppliers hold business license, safety production license, ISO quality/environmental management certifications to ensure legal operation and standardized management.

- Business History & Scale: Prioritize long-standing suppliers with good reputation; assess production scale (plant area, production lines, workforce) for stronger capacity to meet large-project needs.

Evaluate asphalt plant supplier product technology and quality

The technical level and quality of the asphalt mixing plant directly determine its production efficiency and the quality of the output asphalt mixture.

- Technological Advancement: Ensure the plant uses advanced processes (automatic metering, intelligent temperature control) for accuracy and stability. Check for energy-saving/environmental tech (dust recovery, exhaust treatment) to reduce costs and pollution.

- Product Quality Inspection: Verify strict inspection processes for raw materials, semi-finished/finished products. Request quality reports for key components and visit workshops to assess production control measures.

Consider after-sales service capabilities of asphalt plant supplier

High-quality after-sales service can ensure the normal operation of the equipment, reduce downtime and reduce the risk of use.

- Response & Maintenance: Ask about after-sales response time and on-site maintenance speed; assess the supplier’s team expertise for quick fault diagnosis. Strong capabilities reduce downtime and safeguard project schedules.

- Parts Supply & Training: Ensure timely parts availability to avoid long outages. Check for operator training (operation, maintenance, troubleshooting) to boost skills, minimize misuse-related failures, and extend equipment life.

Compare Prices of asphalt plant supplier

Asphalt plant price is an important consideration when choosing an asphalt mixing plant supplier, but you should not only focus on the price, but also pay attention to the benefits brought by the equipment.

- Price Rationality: Obtain multi-supplier quotes; analyze cost components (purchase, transport, installation). Compare similar products to assess fairness. Avoid unrealistically low prices risking quality/after-sales issues.

- Cost-Effectiveness: Holistically evaluate quality, technology, and after-sales service. Prioritize suppliers within budget that balance upfront costs with long-term savings (e.g., higher-tech models reducing total ownership costs).

Choosing a suitable asphalt mixing plant supplier is to ensure the smooth progress and long-term benefits of the project. From qualification review to technical expertise, after-sales service, and overall cost-effectiveness, every aspect is crucial. Only through comprehensive evaluation and careful decision-making can you find a reliable and efficient asphalt plant supplier, ensuring smooth project execution, efficient production, and a more valuable investment. Remember, choosing the right supplier means securing safety and peace of mind for your project.

Trusted Asphalt Plant Suppliers, Online to On-Site

After understanding how to evaluate suppliers, the next step is to actually find qualified, best asphalt plant manufacturers. There are many asphalt mixing plant suppliers on the market. How to screen out truly reliable companies from massive amounts of information is a question that every customer who purchases an asphalt mixing plant will be concerned about. Below, we’ll analyze effective ways to find asphalt plant suppliers through various channels, including online searches, B2B platforms, peer recommendations, industry exhibitions, and on-site inspections, helping you save time and efficiently identify the best partners.

Compare websites and customer cases using Google searches

Use B2B platforms for initial screening

Get recommendations from peers or visit industry trade shows

Visit the factory and service team on-site

Finding a reliable asphalt mixing plant supplier requires a combination of methods and approaches. Online searches, B2B platforms, peer recommendations, and industry exhibitions can all serve as initial screening tools, but on-site inspections are crucial for ultimately confirming a supplier’s reliability. Through a systematic and comprehensive search and evaluation process, you can identify an asphalt plant supplier with proven technical expertise, reliable service, and a strong reputation, ensuring smooth project implementation and long-term investment value.

Macroad — A Globally Trusted Asphalt Plant Supplier

If you’ve read this carefully, it means you’re already carefully planning your asphalt mixing plant supplier selection. As a professional asphalt mixing plant supplier with 20 years of experience in the asphalt mixing plant market, Macroad prioritizes maximizing returns on every investment, from equipment development to on-site service.

Factory-Trade Integration: Reliability Starts at the Source

Our 20,000 square meter, self-owned production facility in the Jiaozuo Industrial Zone in Henan Province ensures comprehensive quality control for every piece of equipment. Core components such as the wear-resistant lining of the mixing unit, the welding precision of the drying drum, and the control cabinet program are all rigorously controlled by experienced technicians. Each weld undergoes three hydraulic pressure tests, and each piece of equipment undergoes a 72-hour full-load continuous operation test before shipment, accompanied by an energy consumption and failure rate inspection report. This allows for rapid production upon receipt, minimizing initial efficiency losses.

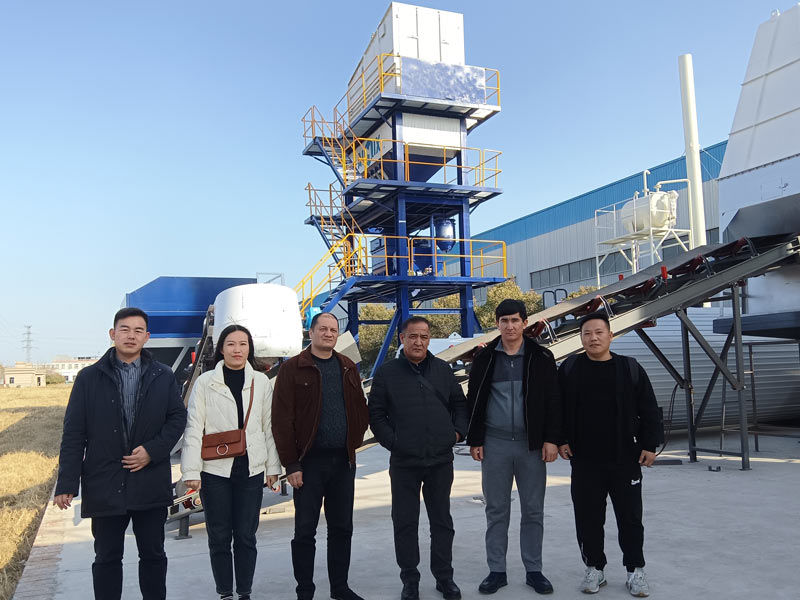

Five Local Networks for Fast Global Response

Macroad, an asphalt equipment manufacturers, has over 10 years of experience in the asphalt industry. With Macroad’s asphalt mixing plants now deployed worldwide, Macroad has established five local service centers in Indonesia, Malaysia, Russia, Uzbekistan, the Philippines, and Kazakhstan. These centers, equipped with a team of professional engineers and a standardized spare parts inventory, offer a rapid service network with 48-hour on-site response in core markets and 72-hour arrival time in remote areas. From equipment commissioning to operations and maintenance support, Macroad provides localized technical services to ensure comprehensive project coverage.

Certified Core Technologies, Setting the Industry Quality Standard

- Internationally recognized certifications: Products are EU CE certified (dust emissions ≤ 30mg/m³, safety indicators meet EN 13139 standards), complying with stringent global environmental and safety regulations. ISO 9001 quality management system certification ensures full control from R&D to delivery.

- Core patented technologies: 5 exclusive patents, including a utility model patent for a mobile drum mixer, a patent for a highly integrated asphalt mixing plant structure, and intelligent dust recovery technology.

Regional Practices, Proven Full-Scenario Solutions

- Southeast Asian Market:

- Central Asian Market:

Uzbekistan, Kyrgyzstan, Kazakhstan

- Other key regions:

As a professional asphalt plant supplier, Macroad is committed to providing reliable, efficient equipment and comprehensive technical services to our global customers. From equipment research and development, production, installation, and after-sales support, every step is centered on the smooth progress of our customers’ projects. Choosing Macroad means choosing a trustworthy asphalt plant supplier who can ensure your asphalt mixing plant project operates efficiently and stably over the long term, maximizing the value of your investment.