Smart Control, Efficient Production

Client Testimonial: Strategic Partner of Fortune Global 500 Companies

Want smooth, durable roads, on-time completion, and within budget? The key lies in an efficient and stable asphalt plant. It precisely mixes aggregate, mineral powder, and asphalt, mixing at high temperatures to consistently and stably produce high-quality asphalt that meets standards.

Macroad asphalt plants not only offer high production efficiency and low energy consumption, but also maintain stable operation in diverse climates and working conditions, minimizing material waste and lowering maintenance costs. Whether working on highways, urban roads, or airport access roads, plant asphalt ensure on-time, quality, and budget delivery, maximizing the value of every ton of material.

Macroad helps global projects achieve efficient construction

In Kyrgyzstans’s Mountains, ALQ160 Breaks Infrastructure Barriers with High Efficiency

- Capacity: 160tph

- The project team reported: The asphalt plant achieved a stable daily output of 1,400 tons of mixture in mountainous construction at 1,800 meters above sea level. The heating efficiency of the drying drum was 12% higher than expected, effectively ensuring the schedule of the cross-border highway project.

Malaysia’s Hot-Humid Zones: ALQ120 Asphalt Plant Defines Reliability with Stability

- Capacity: 120tph

- On-site engineers: On-site engineers noted that in Malaysia’s climate with an average annual humidity of 90%, the asphalt plant in Malaysia‘s electrical system’s moisture-proof design performed excellently, with no humidity-induced shutdowns for 6 consecutive months. The service life of the mixer’s wear parts was 30% longer than similar equipment, significantly reducing maintenance costs.

ALYQ90 Asphalt Plant New Equipment Debuts: Proving Technical Strength with First-Use Compliance

- Capacity: 90tph

- Operators Feedback: Operators reported that the new plant asphalt’s intelligent touch system reduced startup preparation time from 40 minutes (traditional equipment) to 15 minutes. The automatic calibration function could real-time correct mixing ratio deviations caused by fluctuations in aggregate moisture content. In the first month of production, it completed 3,000 tons of mixture production, with all indicators exceeding project acceptance standards, significantly reducing manual monitoring intensity.

Fiji Island Projects: ALT40 Asphalt Plant Gains Popularity with Flexible Design

- Capacity: 40tph

- The operation manager: The operation manager stated that the bitumen mix plant’s modular design reduced logistics costs by 40% for transportation across Fiji’s islands. The quick-install system enabled production within 24 hours of unloading, perfectly adapting to the fragmented needs of scattered road repairs on islands.

ALT120 Empowers Guatemala: A Durable, Low-Consumption Choice for Infrastructure

- Capacity: 120tph

- Project feedback: The construction party evaluated that during the rural road network renovation in Guatemala, the bitumen mixing plant operated continuously for 120 days at high intensity (10 hours daily) with a failure rate below 0.5%. Its low fuel consumption design (8% lower than the standard) saved significant fuel costs for the budget-constrained project.

ALYT120 Asphalt Plant Empowers Dominican Republic: Benchmark of High-Quality Output in Tropical Climate

- Capacity: 120tph

- Prpject Supervisor Prise: The project supervisor noted that in high-temperature rainy conditions, the anti-sticking design reduced asphalt agglomeration, with mixture uniformity reaching 98% (8 percentage points above local standards). It produced 80 tons in 6-hour rainy intervals, with precise metering ensuring consistent road strength, earning recognition from local transportation authorities.

Asphalt Plant Selection Made Easy – Macroad Product Overview

In the current market, asphalt mix plant offer a wide variety of equipment types and performance. Choosing the most suitable equipment based on specific project requirements and construction environments has become a crucial challenge for many project managers and procurement professionals.

Leveraging years of industry experience and technological innovation, Macroad offers a diverse product range encompassing both stationary and mobile asphalt mixer plant, as well as dynamic and drum mixing equipment, providing tailored solutions for projects of varying scales and working conditions. Whether on highways, urban roads, rural roads, or internal park access roads, Macroad asphalt plant for sale ensures smooth project progress with efficient, precise, and durable performance.

The following content will comprehensively analyze the core advantages and application scenarios of each equipment model, helping you clarify your selection process and easily make the optimal decision, ensuring a win-win situation for both construction efficiency and return on investment.

ALQ series asphalt plants for sale

- High Heating Efficiency: The drying drum operates in a co-current mode to remove moisture from cold aggregate. Air drawn from the center of the drum ensures high thermal efficiency and accelerates heating.

- High-Precision Weighing System: Low weighing error, within ±0.5% for aggregates and within ±0.25% for powder and asphalt, ensuring high-quality finished products.

- Reliable and Durable: Upgraded wear-resistant structures, including the mixing blades, hot aggregate silo, and finished product silo, along with predictive maintenance technology, ensure that key components can handle millions of tons of material output.

- Suitable Applications: This asphalt batching plant suit for arge-scale highway construction projects (with construction periods exceeding one year), urban ring road construction, and regional asphalt mixing plants (supplying to surrounding projects).

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Output(t/h) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Cold Aggregate Feeding System | 4×4.5m³ | 4×6.5m³ | 4×8m³ | 4×8m³ | 5×9m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Hopper Capacity(m) | 4*4.5 | 4*6.5 | 4*8 | 4*8 | 5*9 | 5*12 | 5*12 | 5*12 | 6*15 |

| Collect Belt Capacity(t/h) | 60 | 80 | 100 | 120 | 140 | 200 | 220 | 280 | 360 |

| Dryer Size(m) | φ1.2*5.2 | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 | φ2.2*9 | φ2.6*9 | φ2.6*9.5 | φ2.8*10.2 |

| Dryer Capacity (t/h) | 60 | 80 | 100 | 120 | 140 | 180 | 240 | 260 | 360 |

| Fuel Max Consumption(kg/h) | 300 | 450 | 550 | 700 | 950 | 1200 | 1400 | 1700 | 2250 |

| Vibrating Screen(Layer) | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 6 |

| Aggregate Metering hopper(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mineral Flour Metering hopper (kg) | 120 | 150 | 200 | 200 | 300 | 300 | 320 | 600 | 700 |

| Bitumen Metering hopper (kg) | 100 | 120 | 150 | 150 | 250 | 250 | 250 | 480 | 500 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 500 | 800 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cycle Time(s) | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Dust filter (Bag dust filter) | |||||||||

| Filter Area(m2) | 230 | 300 | 420 | 480 | 550 | 650 | 700 | 1050 | 1350 |

| Draught Fan(kw) | 22 | 30 | 45 | 55 | 90 | 110 | 2*75 | 2*90 | 2*110 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 | 140-180 |

ALYQ series asphalt plants for sale

- Intelligent Operating System: The mobile asphalt batch mix plant equipped with an AI bee-controlled system, it offers fully automatic operation and intelligent early warning, supports one-touch recipe switching, and features a mobile app-based remote monitoring system, reducing labor by 50%.

- High-Efficiency Mixing and Screening System: A patented design of boiling mixing and large-channel screening improves efficiency by 15%. Maintenance is simplified, with core components requiring five years of replacement, and the vibrating screen motor requiring 2,000 hours of maintenance.

- Precision Metering System: AI-powered automatic weighing reduces errors to 1%, eliminating waste and saving approximately 80 tons of material daily. Equipped with an efficient electronic scale.

- Suitable Scenarios: Rural road reconstruction (multi-section, dispersed construction), emergency repairs (such as road repairs after heavy rain), and internal roads within large industrial parks (phased construction).

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 |

|---|---|---|---|---|

| Output (t/h) | 60 | 80 | 100 | 120 |

| Hopper Capacity(m) | 4*6.5 | 4*7.5 | 4*7.5 | 4*7.5 |

| Collect Belt Capacity (t/h) | 80 | 100 | 120 | 140 |

| Dryer Size(m) | φ1.5*6 | φ1.5*6.7 | φ1.65*7 | φ1.8*8 |

| Dryer Capacity(t/h) | 80 | 100 | 120 | 140 |

| Fuel Max Consumption(kg/h) | 450 | 550 | 700 | 950 |

| Mixing Tower(kW) | 54 | 63.5 | 104.5 | 125 |

| Vibrating Screen (Layer) | 4 | 4 | 4 | 4 |

| Aggregate Metering hopper(kg) | 800 | 1000 | 1300 | 1500 |

| Mineral Flour Metering hopper(kg) | 150 | 200 | 200 | 300 |

| Bitumen Metering hopper(kg) | 120 | 150 | 150 | 250 |

| Weighing accuracy | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% | aggregate:±0.5% Mineral Flour:±0.25% Bitumen:±0.25% |

| Mixer Capacity(kg) | 800 | 1200 | 1300 | 1700 |

| Cycle Time(s) | 45 | 45 | 45 | 45 |

| Filter Area(m2) | 370 | 420 | 480 | 510 |

| Draught Fan (kw) | 30 | 45 | 55 | 90 |

| Asphalt Temperature (⊥) | 140-180 | 140-180 | 140-180 | 140-180 |

| Total power(kw) | 200 | 300 | 350 | 380 |

ALT series asphalt plants for sale

- Efficient and Continuous Production: The continuous mixing design ensures uniform material temperature and stable mixing quality, making this stationary asphalt mix plants suitable for large-scale, continuous production.

- Energy-Saving and Environmentally Friendly: The optimized combustion system achieves high thermal efficiency, and advanced dust removal reduces emissions, meeting environmental standards.

- Compact Structure and Easy Maintenance: The asphalt plant’s compact design occupies a small footprint, and key components are easily maintained and replaced, reducing operating costs.

- Suitable Applications: Large and medium-sized road paving projects, as well as projects requiring continuous production and tight deadlines.

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 3 | 3 | 7 | 7 | 9 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option: Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter | Bag Dust Filter |

ALYT series asphalt plants for sale

- Towerless Design: Its low profile ensures asphalt plant can adapt to narrow spaces, uneven terrain, and urban construction zones.

- Compact and Mobile: Its built-in mobile chassis allows for easy transportation and rapid deployment.

- Continuous and Precise Operation: The mobile drum mix plant integrated drying and mixing drum ensures uninterrupted production with a temperature accuracy of up to ±0.5°C.

- Suitable Applications: Urban road maintenance and repair, small, dispersed construction sites, emergency repair projects, and multi-site rotation.

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 |

|---|---|---|---|---|---|

| Output (t/h) | 20 | 40 | 60 | 80 | 100 |

| Power Fuel Oil(kw) | 34 | 65 | 105 | 135 | 170 |

| Power Burning Coal (kw) | 40 | 75 | 120 | 165 | 200 |

| Cold Aggregate Feeding System | 3.5m3*1 | 4m3*4 | 4m3*4 | 6.5m3*4 | 6.5m3*4 |

| Finihnsed Asphalt Storage Bin (t) | 2 | 2.5 | 4.5 | 5 | 7 |

| Asphalt Temperature (℃) | 120-180 | 120-180 | 120-180 | 120-180 | 120-180 |

| Fuel Consumption Fuel Ol (kg/t) | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 | 5-7.5 |

| Fuel Consumption Buning Coal(kg/t) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Asphalt Tank (t) | 10 | 20 | 30 | 30 | 35 |

| Control Room(m) | 2.2 | 2.2 | 3 | 3 | 3.5 |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

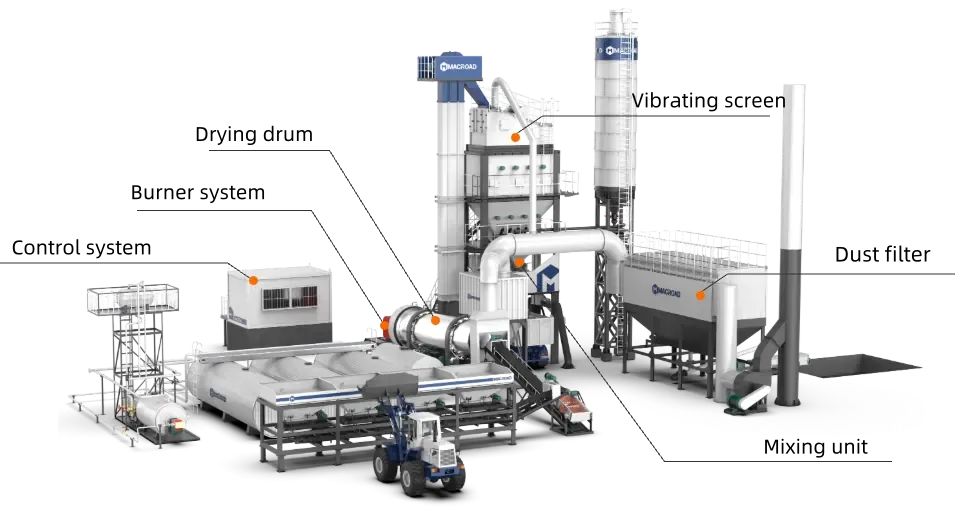

Asphalt Mixing Plant Operating Logic and Core Components

We’ve previously introduced the performance advantages and applicable scenarios of different types of asphalt plants series. However, to truly maximize the efficiency of the asphalt hot mix plant, understanding what is an asphalt plant and its operating logic and the role of its core asphalt plant components is crucial. The following part will step through the complete workflow of an asphalt mixing plant, from raw material input to finished product output, and explain the key components involved in each step to help you gain a clearer understanding of the equipment’s operating principles.

Raw Material Storage and Transportation

- The cold silo (for storing aggregates of varying sizes) is conveyed to the next stage via a belt conveyor according to the required mix ratio, completing the initial transfer of raw materials.

- Asphalt Plant Components involved: Cold silo, belt conveyor

Drying and Heating

- The drying drum receives the conveyed aggregates and uses a burner to heat and dry them to remove moisture.

- Asphalt Plant Components involved: Drying drum, burner

Screening and Grading

- The heated aggregates enter a vibrating screen, where they are screened into aggregates of varying particle sizes and temporarily stored in corresponding hot aggregate silos.

- Asphalt Plant Components involved: Vibrating screen, hot aggregate silo

Precision Batching

- Aggregates from the hot aggregate silo, mineral powder from the powder silo, and asphalt from the asphalt tank are weighed to the set ratio using their respective weighing devices (aggregate scale, powder scale, and asphalt scale).

- Asphalt Plant Components involved: Powder silo, asphalt tank, weighing devices (aggregate scale/powder scale/asphalt scale)

Mixing System

- The weighed aggregates, mineral powder, and asphalt are fed into the mixing tank, where high-speed mixing forms a uniform asphalt mixture.

- Asphalt Plant Components involved: Mixing tank

Finished Product Storage and Discharge

- Qualified asphalt mixture is stored in the finished product silo and discharged through a controlled discharge gate for transport to construction equipment.

- Asphalt Plant Components involved: Finished product silo, discharge gate

Macroad Asphalt Plant Core Advantages: Innovation Driving Customer Value

After understanding how does a asphalt plant work, Macroad’s groundbreaking asphalt plant design in various core systems can further empower projects from the perspectives of efficiency, cost, and risk control. The following analyzes how its technological advantages translate into actual benefits for customers, focusing on six core systems in the asphalt production.

Cold Aggregate Supply System: Stable feed, reduced labor and downtime

- Technical Advantages: Integrated with 3-6 aggregate metering and conveying functions, asphalt production plant equipped with an inspection platform, low-material alarms, and automatic deviation-correcting rollers, it provides full process visualization. The PLC control system automatically adapts to asphalt processing plant rhythm, eliminating manual monitoring. Multi-bin intelligent storage supports dynamic bin management. Variable frequency feeding technology adjusts the feed rate based on demand. Combined with a countercurrent drying structure with an insulation layer, the aggregate moisture content is kept stable at ≤0.5%.

- Customer Benefit: Avoids feed interruptions caused by human error, blockages, or material breaks, reducing reliance on skilled labor. Safety devices reduce the risk of unplanned downtime of bitumen plant. Countercurrent drying technology balances energy conservation with uniform drying, ensuring production continuity and indirectly reducing lost time.

Drying System: Efficient Temperature Control, Adaptable to Complex Operating Conditions

- Technical Advantages: Optimized blade structure and material curtain design in asphalt plant equipment improve heat exchange efficiency, and the burner automatically purges to prevent clogging. Waste heat recovery technology maintains a stable drying environment in the drum, adapting to humid conditions such as the rainy season. This synergistically integrates with the countercurrent drying technology of the cold material supply system to enhance aggregate dehydration.

- Customer Value: This eliminates amp asphalt mixing plant downtime in humid weather, reduces manual intervention and maintenance frequency, and lowers energy consumption while ensuring aggregate drying quality, laying a stable foundation for subsequent screening and mixing processes.

Weighing System: Accurate Mixing, Simplified Approval Process

- Technical Advantages: Dynamic secondary metering correction technology controls mix accuracy, achieving an aggregate error of ≤±0.5% and a powder and asphalt error of ≤±0.25%. The powder metering hopper is directly connected to the asphalt plant parts mixer to shorten mixing time, and a four-stage vibrating screen separates aggregates of varying particle sizes to ensure uniform particle shape. The fully enclosed metering structure reduces material loss and dust pollution, and production data can be uploaded to the data center via the Internet.

- Customer Value: Avoids raw material waste and improves mixture stability. The fully enclosed asphalt mixing plant layout reduces dust pollution control costs. Production data is retained for repeated review and access.

Mixing System: Improves Quality, Reduces Rework Risk

- Technical Advantages: A dual-shaft batch mixing asphalt plant design with upgraded wear-resistant asphalt plant wear parts enables 360-degree mixing and achieves 100% asphalt coverage. The IoT system optimizes the mixing path in real time, and intelligent temperature control prevents temperature fluctuations. The upgraded wear-resistant structure supports million-ton discharge capacity and integrates with the constant temperature insulation bins in the finished product storage system to ensure stable finished product temperature.

- Customer Benefit: Reduces rework due to substandard mixture quality, reducing maintenance costs at the source. Intelligent temperature control and constant temperature storage prevent temperature fluctuations that affect construction quality, extending road life. The million-ton wear-resistant design of bitumen manufacturing plant reduces long-term operation and maintenance costs.

Dust Removal System: Meets Environmental Standards, Reduces Approval and Installation Costs

- Technical Advantages: A three-stage filtration process combined with dual-stage dust removal (cyclone + bag filter) achieves a dust capture rate exceeding 99% and an emission concentration below 50mg/m³, exceeding national standards. Flue overtemperature protection and flexible telescopic ducting (allowing ±3cm installation tolerance) accommodate asphalt plant installation errors, while pulse automatic cleaning extends equipment life. Factory pre-testing allows for flexible duct angle adjustment.

- Customer Value: Directly meets local environmental requirements, eliminating the need for re-construction due to angle deviations. The flexible installation design of asphalt mix plant for sale reduces secondary work required due to angle deviations. Pulse cleaning reduces maintenance frequency, and dual filtration technology reduces environmental compliance costs.

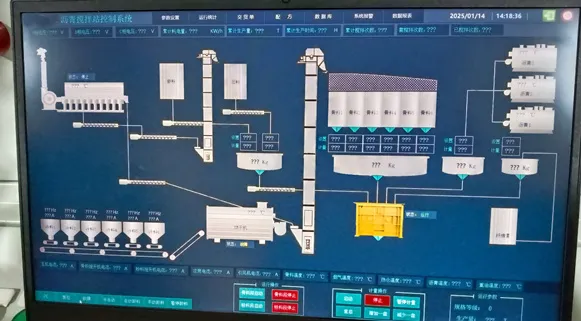

Control System: Simplifies Operation, Lowers Human Capacity

- Technical Advantages: Integrates 15 self-test routines, one-touch start/stop (simplifying 50 traditional steps), and remote debugging capabilities. Supports multi-mode operation and digital monitoring via a computer, touchscreen, and physical buttons. The IoT system collects real-time asphalt plant process operating status, automatically sends maintenance reminders and fault warnings, supports remote parameter adjustment, and integrates with intelligent modules in the mixing and weighing systems to achieve full process automation.

- Customer Benefit: Simplifies complex operations into standardized processes, shortening new employee training by 50% and reducing human error. Remote monitoring and intelligent warnings reduce bituminous mixing plant downtime, and multi-mode operation adapts to different habits, maximizing equipment uptime.

Through the collaborative design of the above reliable asphalt plant systems, Macroad transforms technological advantages into tangible value in reducing costs, improving efficiency, and mitigating risks, helping customers achieve high-quality delivery in projects with tight deadlines and complex working conditions.

Asphalt Mixing Plant Price Structure and Return on Investment

For investors planning to invest in an asphalt mixing plant, clarifying the cost structure and revenue generation is crucial for making a sound decision. Previously, we examined the logic behind equipment selection. The differences in price structure and the cost-benefit logic under different operating asphalt plant model directly determine the rationality of the investment and its payback period. The following parts, from a practical investment perspective, details the factors influencing asphalt plant cost and the key steps to achieving a return on investment, helping you make the final decision.

Key Factors Affecting Asphalt Plant Prices

Production Capacity and Type

- Hourly production capacity is tiered: 20-60 tons (small), 80-160 tons (medium), and 160 tons and above (large). Each increment increases the price by 30%-50%.

- Differences in Equipment Type: Batch type asphalt plant machine is 10%-15% more expensive than continuous asphalt manufacturing plant of the same production capacity because batch plants require more sophisticated weighing and mixing systems.

Core Configuration Levels

- Basic Configuration: Meets basic asphalt concrete plant production needs (simple weighing, standard wear-resistant parts). Prices are lower, but maintenance is more frequent.

- Advanced Configuration: Includes high-precision metering (error ≤ 0.5%) and highly wear-resistant mixing blades (lifespan increased by 50%). Bitumen production plant prices increase by 20%-30%, but reduce material waste and replacement costs.

- Environmental Protection: Adds multi-stage dust removal in asphalt mixing plant (dust emissions ≤ 50mg/m³). Prices increase by 30%-40%, but can meet environmental regulations in regions with strict regulations and avoid fines.

Mobility and Installation Requirements for Asphalt Plant

- Stationary type: Requires a concrete foundation, resulting in high initial construction costs (approximately 10%-15% of the equipment price), but the asphalt concrete mixing plant itself is relatively inexpensive, making it suitable for long-term, fixed-site installation.

- Mobile type: Comes with a built-in chassis and quick-installation structure. The asphalt mixing plant amp price is 15%-20% higher, but requires minimal construction, resulting in low relocation costs and suitable for multiple site rotations.

Additional Services and After-Sales

- Installation and Commissioning: Manufacturer’s on-site service accounts for approximately 5%-8% of the equipment price and includes asphalt plants calibration and system commissioning, ensuring better initial operational stability than self-installation.

- Warranty: Basic warranty for asphalt mixing equipment is 1 year, and extending to 3 years requires an additional 5%-10% fee to cover the repair costs of key components (such as motors and sensors).

Macroad Equipment Price Reference

The following Macroad series asphalt mixing plant for sale prices are for reference only.

Cost Structure and Return on Investment Logic for Different Operating Models

Whether asphalt plant operation for own use, leasing to external parties, or undertaking processing for supplied materials, the cost-to-profit thresholds vary. Only by specifically analyzing where the costs are spent and where the profits come from for each model can we develop a precise return on investment strategy and know the logic behind how profitable are asphalt plants.

Owned Project Construction

Cost Structure

- Fixed costs: Asphalt mixing plant equipment purchase price (including loan interest, if paid in installments), site rental/infrastructure amortization, and annual equipment depreciation (accrued over 5-8 years).

- Variable costs: Aggregate/asphalt procurement (60%-70% of total cost), fuel/electricity (10%-15%), operator labor (2-3 people/shift, total monthly salary 10,000-20,000 $), and routine maintenance (approximately 5,000-10,000 $ per month, including replacement of wearing parts).

- Hidden costs: Idle asphalt plant business for sale during project downtime (approximately 3,000-5,000 $ lost in production capacity per day), and the risk of raw material price fluctuations.

Payback Logic: Improve Bitumen processing plant Utilization + Control Raw Material Loss

- Undertake projects with continuous construction periods (such as highway sections), ensuring at least 200 days of annual construction start-up time to dilute fixed costs;

- Optimize batching solutions and reduce asphalt/aggregate waste through precise metering (every 1% reduction in loss results in an annual savings of 50,000-100,000 $);

- Prioritize the use of proprietary raw material sources and purchase in bulk to reduce purchase prices (saving 500,000-100,000 $ per ton of asphalt, or 200,000-500,000 $ per year).

Leasing Operations

Cost Structure

- Fixed costs: Model asphalt plant purchase price, transport vehicle depreciation, office/parts warehouse rental.

- Variable costs: Equipment relocation and transportation fees (5,000-20,000 $ per trip), on-site operator salaries (based on shifts, approximately 1,000-2,000 $/day), and maintenance costs (10,000-20,000 $/month due to frequent use).

- Risk costs: Equipment damage compensation (especially when leasing to new operators), and off-season idleness (e.g., in extremely cold regions, where there may be no orders for 3-4 months).

Payback Strategies: Increase rental rates + differentiated pricing

- Focus on short-term emergency orders (e.g., road repairs), offering a 20%-30% premium to cover idleness risks;

- Offer equipment + operator + consumables packages, charging 8,000-12,000 $ per day (30% higher than simply leasing asphalt plants);

- Sign annual framework agreements with regional engineering companies to guarantee a base rental period (e.g., 150 days per year) and lock in cash flow.

Processing with Custom Materials

Cost Structure

- Fixed costs: new asphalt plants for sale cost, site rental, processing license application and annual review fees.

- Variable costs: Processing energy consumption (fuel/electricity, approximately 30-50 $ per ton of material), processing labor (1-2 people/shift, monthly salary 8,000-15,000 $), environmental consumables (such as dust filter bags, 3,000-5,000 $ per month).

- Settlement costs: Working capital tied up by customer accounts (usually 1-3 months), and advance payments to raw material suppliers.

Break-even Logic: Expand Processing Volume + Control Unit Energy Consumption

- Set tiered processing fees (e.g., 80 $/ton for processing up to 5,000 tons per month, 70 $/ton for excess) to attract additional orders;

- Optimize production schedules to avoid peak electricity usage (industrial electricity prices are 50% higher during peak hours than during normal hours) and reduce energy costs;

- Collaborate with nearby small construction teams to take on small orders (e.g., rural road repairs) to fill idle periods.

Asphalt Mixing Plant Full-Cycle Maintenance Guide

Regardless of the operating model, the asphalt plant for sale’s stable operating time directly impacts its payback period—avoiding one unplanned downtime can generate an additional day of productive revenue. The core value of maintenance lies in keeping the asphalt mixing plants in good condition from the moment it’s first started up. This prevents hidden damage during the initial run-in phase and reduces the probability of failure over the long term. The following describes key operational points for both initial operation and subsequent routine maintenance.

First Run: Conduct Pre-Startup Inspections and Run-in Period Maintenance

The initial startup is the foundation of equipment life. 90% of initial failures are due to improper installation and commissioning or improper run-in procedures. Pay special attention to the following three aspects of asphalt mixing plants for sale:

Comprehensive Pre-Startup Inspection

- Mechanical Components: Check the plant mix asphalt mixing drum blades and vibrating screen for misalignment (clearance error must be ≤ 2mm). Check the torque requirements for all connecting bolts (especially at the drying drum and frame connection) (retighten according to the instructions) to prevent abnormal noise or ashplant plant component detachment during operation.

- Electrical System: Test the linkage between the control system and sensors (for example, whether the weighing hopper automatically stops feeding when it reaches the set weight). Verify the responsiveness of safety devices such as the emergency stop button and overload protection to prevent sudden shutdowns caused by circuit failures.

- Lubrication and Media: Add the specified lubricant grade according to the model (for example, use No. 3 lithium-based grease for the agitator shaft bearing). Check the fuel, hydraulic oil, and coolant levels and purity (remove any trapped air in the pipes before first use) to prevent component wear due to oil starvation or impurities.

Post-Startup Run-in Procedures

- No-load Test Run: After the initial startup, run the asphalt mixing plant pdf at no load for 30 minutes to observe the smooth operation of all components (e.g., vibration screen amplitude deviation ≤ 5mm). Monitor the drying drum and mixing tank for any abnormal noise (normally, there should be no metallic friction).

- Gradual Loading: Operate at 50% of the designed capacity for the first three days, increasing to 80% on days 4-7 to avoid overloading components (especially power components such as motors and reducers) caused by sudden full-load operation.

- Daily Review: Record key data during the run-in period (e.g., fuel consumption, material temperature fluctuations, and bituminous plant vibration levels). If any parameter is found to be persistently abnormal (e.g., material temperature deviation exceeding ±10°C), shut down the machine to inspect the heating system or sensor calibration to prevent minor issues from accumulating into major failures.

Initial Parameter Calibration

- Metering System Calibration: After the run-in period, recalibrate the aggregate, powder, and asphalt weighing devices using standard weights to ensure that the error returns to within ±0.5% (aggregate) and ±0.25% (powder/asphalt) to avoid measurement errors caused by mechanical looseness.

- Temperature Control System Debugging: Test heating efficiency under different ambient temperatures (e.g., sunny vs. cloudy days). Reset the drying drum flame size and aggregate residence time parameters to ensure material temperature stability (fluctuation ≤ ±5°C).

- Record Baseline Values: Archive post-run-in data (e.g., fuel consumption at full load, motor current) as equipment baseline parameters. Use this as a reference during subsequent maintenance to quickly identify asphalt plant working safety (e.g., a sudden 15% increase in fuel consumption may indicate a burner failure).

Subsequent Operation: Establish a Closed Loop of Daily and Regular Maintenance

After the bitumen plant design enters the stable operation phase, the core of maintenance is prevention. Regular operation reduces unexpected failures and extends the lifespan of core components.

Daily Maintenance

- Pre-shift Inspection: Check the cold material bin belt for deviation (the gap between the edge and the baffle must be ≥5cm), check the dust removal duct for blockage, and check the asphalt pump pressure gauge pointer is within the normal range.

- Post-shift Cleaning: Clean any remaining mixture from the mixing tank (especially in corners and crevices to prevent wear on the blades after hardening). Rinse the weighing hopper and discharge port (to prevent powder clumping and metering errors). Clean dust from the dust filter bag surface and backflush with compressed air to maintain air permeability.

Regular Maintenance

- Short-term (weekly): Check the grease level at each lubrication point (for example, the vibrating screen eccentric shaft should be regreased every 7 days). Tighten loose parts such as the pulley guard screws. Test the burner flame. A normal flame should be a blue cone to avoid heat waste caused by a yellow flame.

- Mid-term (monthly): Calibrate the weighing system (using standard weights to ensure the error is within ±0.5%), check wear on wear-resistant parts (for example, if the mixing blade is worn more than 1/3 of its original thickness, turn it over to extend its lifespan), and clean the fuel filter to prevent impurities from clogging the fuel injectors.

- Long-term (annual): Inspect the wall thickness of the drying drum (focusing on the 1/3 area at the feed end; wear ≤3mm can continue to be used), replace aging seals (such as the mixing drum end cover seal), and perform dust removal and line insulation testing on the electrical cabinet to prevent moisture-induced short circuits.

Fault Warning and Emergency Response

- Abnormal Monitoring: Identify potential problems (such as bearing oil depletion and impeller fouling) in advance using historical data recorded by the control system (for example, a sudden 10% increase in average fuel consumption over the past three days) or sensory evaluation (for example, a dull motor sound).

- Simple troubleshooting: If you encounter a slight blockage (such as the discharge port of a hot aggregate silo), you can first shut down the equipment and tap the silo wall with a wooden hammer to vibrate and clear it (do not use iron tools to pry it hard to prevent the silo from deforming). If the weighing error exceeds the standard, first check whether the sensor is loose (it can be restored by re-fixing and calibrating).

Initial maintenance, through comprehensive inspections for installation hazards, scientifically controlled run-in loads, and precise calibration of operating parameters, can mitigate initial failures at the source. Subsequent maintenance relies on routine care and regular inspections to slow component wear and reduce the likelihood of unplanned downtime. This combination of two phases significantly extends asphalt plant for sale’s trouble-free operation time, maximizing its effective operating time and ensuring every maintenance investment translates into tangible benefits.

Global Asphalt Mixing Plant Market: Why Now’s the Time to Invest

When considering investing in asphalt mixer plant for sale, hidden within market fluctuations are opportunities closely aligned with your business goals. The subtle shifts in the current asphalt plant global market not only signal growing demand but also promise dividends for those who are prepared. Understanding these changes can help you more accurately align your investment with future returns.

The Wave of Asphalt Plant Demand: Two Market Opportunities

- Growth Potential in Emerging Markets: Southeast Asia, Africa, and Latin America are accelerating infrastructure development, with a slew of supporting projects for urban and rural road networks and industrial parks underway. Over the past five years, related investment has grown at an average annual rate of over 7%. These projects require clear equipment flexibility and capacity: a medium-sized machine with a capacity of over 100 tons/hour, equipped with rapid relocation capabilities, can efficiently connect to dispersed construction sites and convert sporadic orders into stable cash flow.

- Replacement Bonus in Mature Markets: Europe, the United States, Japan, and South Korea are focusing on maintaining existing roads, while environmental regulations continue to tighten. Starting in 2026, older equipment that doesn’t meet low-carbon emission standards will be phased out, resulting in an estimated replacement gap of 12,000 units. Equipment equipped with recycled material processing and low-emission combustion systems not only overcomes market entry barriers but also commands a premium based on compliance, with per-ton processing revenue up to 20% higher than that of standard asphalt plant.

Technological Barriers: Making Asphalt Plant Competitive Advantage

- The trust value of intelligent monitoring systems: Project owners now prioritize production transparency. asphalt plant with real-time data monitoring (material temperature, mix accuracy, and energy consumption) can demonstrate professionalism when bidding for large municipal projects, reduce communication costs, and become the preferred and reliable partner of client companies.

- Market accessibility through environmentally friendly configurations: For markets like the EU and North America, environmental standards such as dust emissions ≤10mg/m³ and compliance with nitrogen oxide standards are not additional costs but mandatory entry requirements. Asphalt plant that meets these standards can bypass low-price competition and directly secure high-value-added orders.

The Gift of Trends: Long-Term Benefits of Early Investing Asphalt Plant

- Cost Advantages of Green Transformation: Global infrastructure is shifting towards a circular economy. Equipment capable of processing recycled materials can reduce raw material costs by 30%, aligning with customer budgets and adapting to policy changes, making it a must-have for sustainable projects.

- Stability of Asset Preservation: Green smart asphalt plant significantly outperforms traditional models—after three years of use, its resale value can still maintain over 60% of its original value, reducing investment risk while maintaining flexibility for business adjustments.

The market never waits for those who hesitate. When projects in emerging markets are waiting for equipment to enter the market, old asphalt plant near me in mature markets is being phased out at an accelerated pace, and technological upgrades are constantly raising the ceiling of returns, investing in this moment is not just about purchasing a piece of equipment, but also about anchoring a more certain growth space for the business.

Macroad Services: Your Partner from Start to Success

The success of an asphalt mixing plant investment goes beyond the delivery of a single piece of equipment. From initial requirements matching to stable operation, professional support at every stage directly impacts project efficiency and profitability. Macroad as professional asphalt plant supplier, understands that customers require not only high-quality best asphalt plant but also problem-solvers throughout the entire project lifecycle. The following service system, designed around our customers’ specific needs, covers every critical step, from diagnostics to ongoing operations and maintenance, ensuring reliable support for your best asphalt mixing plant.

Customer Needs Analysis

- Full-Scenario Project Diagnosis: Gain an in-depth understanding of construction scenarios (e.g., heavy-duty highways, rural roads, and freezing resistance in extremely cold regions), production capacity targets (tiered adaptation between 500-6,000 tons per day), and environmental standards, and establish a dedicated project profile.

- Site Survey and Planning: Our engineering team conducts online and on-site research on terrain, climate, power supply, and other parameters, providing targeted layout solutions (e.g., modular assembly for mountainous areas, noise and dust reduction designs for urban areas).

- Transparent Cost and Technical Support: Provides itemized quotes for the entire process (including equipment, transportation, installation, etc.) and cost optimization recommendations. Technical questions are answered through online meetings and on-site demonstrations.

Customized Asphalt Plant Design Solutions

- Precise Equipment Adaptation: Recommends types of asphalt plants (stationary/mobile/batch/drum) and core configurations based on production capacity and application scenarios, including technical parameter comparisons and energy consumption analysis.

- Material and Process Solutions: Provides customized mix ratio recommendations for different scenarios (e.g., anti-rutting formulas for highways, modified asphalt technology for extremely cold regions), matching local construction specifications.

- Personalized Adaptation: Supports customization of equipment appearance, brand logo, voltage and frequency (110V/220V/380V), and multi-language user interface also we will provide the asphalt plant 3d model.

Installation and Coordination Services

- One-Stop Logistics Delivery: Leveraging our global logistics network and standardized production quality control, core components of asphalt mixing plant china (such as agitator blades and burners) undergo 12 inspection steps, and the entire unit undergoes a 72-hour continuous load test, resulting in a 100% factory acceptance rate.

- Transportation options are available for each unit size, with door-to-door tracking services, reducing delivery times by 20%.

- Efficient Installation and Commissioning: Our professional team completes assembly within 72 hours, passing three inspections: no-load, loaded, and environmental inspections. On-site calibration of asphalt plant mix parameters (e.g., asphalt weighing accuracy ±0.25%) is also provided.

Commissioning and Training Services

- Tiered Operation Training: Provides practical training on startup and shutdown, parameter setting, and daily inspections for operators; provides technical training on circuit/oil line troubleshooting and replacement of wearing parts for maintenance personnel.

- Customized Scenario Training: Targeting special scenarios such as extreme cold and high altitude, we offer specialized courses on low-temperature startup maintenance and high-altitude power compensation, along with a supporting Equipment Maintenance Manual and asphalt plant video tutorials.

- System Data Calibration: Generates initial equipment operation records to ensure 98% aggregate screening efficiency, laying the foundation for subsequent stable production.

Asphalt Plant Maintenance and Repair Services

- Proactive Operation and Maintenance Guarantee: Quarterly/semi-annual inspection asphalt plant are developed based on equipment usage frequency and scenarios, covering over 20 areas such as lubrication systems, electrical safety, and software upgrades, and generating an Equipment Health Report.

- Preventive Maintenance: Remotely monitor motor temperature, mixing time, and other data through the IoT, providing early warning of abnormalities such as overheating and overload, reducing the probability of sudden failures by 30%.

- Accessories Supply Chain Guarantee: Directly from the original manufacturer, we provide 100% genuine accessories, with 95% of commonly used accessories in stock and shipped within 48 hours of order. We also support reverse engineering of accessories for older equipment.

Global Market Service and Support

- 24/7 Response Network: Remotely troubleshoot software issues in real time through the PLC system and provide solutions within 2 hours. Engineers will arrive on-site within 48 hours in core areas and 72 hours in remote areas.

- Rapid Troubleshooting: General faults are repaired within 24 hours to ensure uninterrupted project progress.

- Sustainable Value Extension: Regularly promote new industry technologies and provide value-added services such as dust removal system upgrades and AI-powered ratio optimization algorithm iterations to support continuous equipment upgrades.

Every piece of Macroad asphalt plant proves that we don’t just manufacture machines; we create infrastructure solutions tailored to different regions and scenarios. Whether it’s unwavering performance in extreme climates or breakthrough efficiency in complex working conditions, the key is our dedication to making our customers’ projects run more smoothly—and that’s why customers around the world choose to work with us.

If you’re struggling with asphalt plant selection for your project, or want to take your project efficiency to the next level, let’s talk. Tell us about your construction environment, capacity requirements, and concerns, and Macroad will provide a customized answer using our globally proven technology and services. Fill out the form below now, and let’s get started together to make your infrastructure projects more efficient, stable, and competitive.